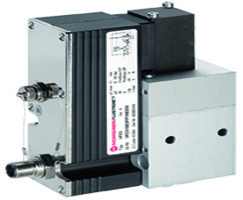

Norgren VP2310BD461MB200 Proportional Valve - IP65

Part Number: VP2310BD461MB200

Quick Summary

Norgren VP2310BD461MB200 proportional pressure control valve enables precise air pressure modulation for automated pneumatic systems. This addresses common pains like drift, sluggish response, and integration complexity when upgrading legacy valves. The device leverages all-digital control electronics for fast, repeatable setpoints and low overshoot, while CE certification and IP65 protection ensure safe operation in harsh environments from factory floors to wash-down zones. Optional external pressure control and serial interfacing with VP-Tool simplify configuration, and fieldbus readiness supports modern control architectures. Its compact VP23 design reduces panel space and installation costs, delivering clear business value for engineering teams and procurement Projects needing reliable, scalable performance.

Product Information

Extended Description

VP2310BD461MB200 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

0 ... 10 bar, 0 ... 145 psi

Port Size

ND8

Control Signal

4-20 mA

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

113.3 mm

Dimensions - Length

136 mm

Dimensions - Width

55 mm

Weight

1.1 kg

Country of Origin

Czechia

Range

VP23

Brand

IMI Norgren

All-digital control electronics deliver closed-loop regulation with repeatable accuracy, reducing process variance and energy waste in high-speed pneumatic lines. This directly translates to higher product quality and lower operating costs in automated assembly and packaging. Variable pressure control from 0 to 10 bar consolidates multiple processes into a single valve, enabling lean inventory and faster changeovers in robot cells and tooling stations. External pressure control on request provides flexible referencing across manifolds, easing retrofits and expansions without new hardware. Serial interfacing with VP-Tool and fieldbus actuation cut commissioning time and wiring, ensuring quicker deployment in modern control architectures. IP65 housing and nitrile seals protect the valve from dust and wash-down fluids, improving uptime in dirty or wet production areas. The compact ND8 port design simplifies installation on standard manifolds, reducing integration effort and panel footprint.

Get a Quick Quote for a Norgren VP2310BD461MB200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2310BD461MB200?

Enquire Now

FAQs

To install VP2310BD461MB200, connect the 4-20 mA control signal and supply as specified, then use VP-Tool for configuration if serial interfacing is enabled. When fieldbus actuation is chosen, integrate the valve into your control network using the appropriate gateway or scanner. Ensure ND8 port connections are secure and verify IP65 enclosure integrity after wiring. This setup reduces commissioning time and supports scalable automation.

Verify the valve is supplied for compressed air with an operating pressure range of 0 to 10 bar and a control signal of 4-20 mA. Confirm ambient temperature compatibility (-5 to 50 °C), IP65 ingress protection, ND8 port size, and weight around 1.1 kg. Ensure seals are nitrile rubber and review the CE certification for regulatory compliance in your region.

Yes. The VP2310BD461MB200 is IP65-rated, providing protection against dust ingress and water jets, making it suitable for manufacturing floors, wash-down zones, and other harsh environments. For longevity, ensure mounting and seals are intact and that the device operates within its -5 to 50 °C range and 0–10 bar pressure window.

Ideal for automated pneumatic systems in packaging, robotics, and assembly lines where stable pressure and fast response improve cycle times and yields. The valve supports VP-Tool interfacing and fieldbus options, making it a strong fit for modern factory automation, material handling, and precision tooling where compact size and reliability matter.

Maintenance benefits come from digital regulation reducing drift and overshoot, extending valve life and lowering unplanned downtime. ROI improves through faster commissioning with VP-Tool and fieldbus options, reduced wiring, and energy efficiency from precise pressure control. CE and IP65 certification further support compliance and reliability in regulated or wash-down environments.