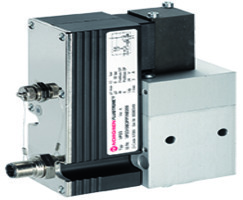

Norgren VP2310BD461MB201 Proportional pressure valve - IP65

Part Number: VP2310BD461MB201

Quick Summary

Norgren VP2310BD461MB201 is a proportional pressure valve enabling precise pneumatic control for automation systems. Many engineers struggle with drift, tuning complexity, and cycle-time impact when using older analog controllers. It carries CE certification and IP65 ingress protection, supporting safe operation and regulatory compliance in demanding environments. For OEMs and maintenance teams, optional fieldbus actuation and VP-Tool interfacing enable faster commissioning, reduced wiring, and scalable control. The all-digital control electronics simplify tuning across pressure ranges, while external pressure control on request accommodates custom system architectures. With IP65-rated rugged construction, installation and service are straightforward in demanding factories. Optional serial interfacing with VP-Tool and fieldbus actuation support seamless integration into existing automation architectures.

Product Information

Extended Description

VP2310BD461MB201 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

7 ... 17 bar, 102 ... 247 psi

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Range

VP23

Brand

IMI Norgren

All-digital control electronics deliver precise pressure regulation with fast, repeatable response. This translates to tighter control of pneumatic actuators and reduced process variation, boosting cycle accuracy on packaging lines, gripping systems, and automated assembly. The digital architecture simplifies tuning across changing loads and environmental conditions, enabling consistent performance without frequent recalibration and minimizing operator intervention in daily setup and changeovers. Variable pressure control with an optional external pressure control mode provides flexibility for multi-step processes. By maintaining setpoints across different loads, designers reduce overshoot, cycle-time gaps, and energy waste. This capability is especially valuable in automation lines that alternate between high-speed positioning and delicate clamping tasks, where precise pressure profiles improve both throughput and part quality without hardware changes. Serial interfacing with VP-Tool and optional fieldbus actuation streamline installation and commissioning. Engineers can load and adjust valve maps remotely, reduce wiring complexity, and accelerate line changes. This complements VP23 family compatibility, enabling seamless parameter transfer between controllers and valves while supporting remote diagnostics and faster fault isolation during production shifts or maintenance windows. Fieldbus compatibility enables Industry 4.0 readiness with centralized monitoring and fault reporting. The VP2310BD461MB201 supports integrated control with standard networks, minimizing cabinet wiring and enabling predictive maintenance through performance trending. In practical terms, users gain quicker startup, simpler expansion of multi-valve manifolds, and easier integration with existing automation architectures across manufacturing floors. Rugged IP65 housing with nitrile seals and CE certification ensures reliable operation in dirty, wash-down, or outdoor environments. The valve tolerates dust, water spray, and broad temperature ranges typical of industrial plants, reducing unplanned downtime and service costs. With a well-documented VP23 interface and proven stability across the 7–17 bar operating window, it delivers sustained performance throughout life-cycle.

Get a Quick Quote for a Norgren VP2310BD461MB201

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2310BD461MB201?

Enquire Now

FAQs

For a new installation, connect the valve to a clean, regulated compressed air supply within the 7–17 bar range and ensure a secure mount with proper clearance for cables and fieldbus connections. Verify IP65 seals are intact, wire the power and fieldbus interfaces according to the VP23 family guidelines, and enable any required VP-Tool or serial interfaces before commissioning.

The valve uses all-digital control electronics to maintain rapid, repeatable pressure regulation. By leveraging precise digital feedback and safe external pressure control if configured, it minimizes overshoot and drift when loads change, ensuring consistent actuator performance across different speeds and force requirements in automated lines.

Yes. The VP2310BD461MB201 supports optional fieldbus actuation and serial interfacing via VP-Tool, enabling parameter transfer, remote diagnostics, and easier commissioning within VP23 ecosystem deployments. This reduces wiring complexity and accelerates integration with existing automation networks in packaging and manufacturing environments.

The valve is CE-certified and IP65-rated, ensuring compliance with international safety and environmental standards. These certifications matter for regulatory acceptance across global manufacturing sites, enabling safer operation in dusty, wash-down, or outdoor environments and reducing the risk of non-conformance during audits.

High-cycle applications benefit from reduced downtime due to robust IP65 construction, nitrile seals, and durable digital electronics that resist wear. The combination of easy commissioning, reduced wiring, and potential energy savings from accurate pressure control translates to shorter maintenance windows, lower service costs, and faster ROI through improved throughput and part quality.