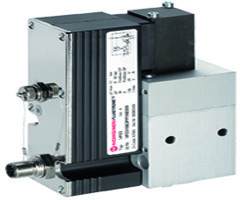

Norgren VP2310BD761MB201 Proportional Valve - IP65

Part Number: VP2310BD761MB201

Quick Summary

Proportional pressure control valve VP2310BD761MB201 provides precise modulation for automated pneumatic systems. This valve addresses the common challenge of fluctuating air supply that can cause inconsistent actuation and downtime in manufacturing lines. The device features all-digital control electronics and a robust IP65 enclosure, with CE conformity for global deployment, and offers optional serial interfacing via VP-Tool as well as fieldbus actuation. By aligning with the VP23 range, it enables scalable control across multiple stations and simplifies integration with standard PLCs. In short, this valve delivers reliable performance, faster commissioning, and reduced total cost of ownership for modern automation environments, making it a solid choice for both new lines and retrofit projects.

Product Information

Extended Description

VP2310BD761MB201 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

7 ... 17 bar, 102 ... 247 psi

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Range

VP23

Brand

IMI Norgren

Feature: All-digital control electronics deliver precise pressure modulation with fast response and repeatable setpoints. Business Impact: This minimizes drift across long production runs, boosting actuation consistency and reducing downtime. Application: Ideal for packaging lines and robotic pick-and-place where stable pressure under variable loads is critical for throughput. Feature: Optional external pressure control and VP-Tool serial interfacing. Business Impact: Enables tailored pressure profiles and simpler changeovers, cutting programming time and risk of misconfiguration. Application: Automotive assembly cells and multi-program automation where different tools require distinct pressure regimes. Feature: Optional fieldbus actuation. Business Impact: Reduces wiring complexity, enables remote control and condition monitoring, and aligns with PLC-centric architectures. Application: Factory networks and MES-integrated lines needing centralized pneumatic control. Feature: IP65 enclosure and CE compliance. Business Impact: Ensures reliable operation in washdown or dusty environments while meeting essential safety standards. Application: Food processing, packaging, and electronics assembly in challenging environments. Feature: VP23 range compatibility and nitrile seals. Business Impact: Simplifies spare parts inventory and maintenance planning while delivering robust performance for clean compressed-air systems. Application: General automation with scalable valve control across multiple stations.

Get a Quick Quote for a Norgren VP2310BD761MB201

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2310BD761MB201?

Enquire Now

FAQs

Install the valve in a clean, dry compressed-air line with secure mounting to minimize vibration. Use the VP23-compatible electrical interface and configure the unit via VP-Tool if serial interfacing is chosen. For fieldbus actuation, connect the actuator to the appropriate network, ensure correct baud rate and termination, and consult the datasheet for wiring diagrams and safety precautions.

Medium: compressed air. Operating temperature: -5 to 50 °C. Operating pressure: 7 to 17 bar (102 to 247 psi). Seals: nitrile rubber. Certifications: IP65 enclosure, CE marking. Part of the VP23 range by IMI Norgren. These specs support precise, repeatable actuation in rugged automation environments.

Yes. The valve provides accurate proportional pressure control essential for repeatable packaging and robotic actuation. With optional external pressure control and VP-Tool interfacing, it supports quick changeovers and complex pressure profiles, while the IP65 enclosure ensures durability in washdown and dusty environments typical of packaging and automated handling lines.

The valve is CE marked and IP65 rated, indicating conformance with essential safety and environmental standards and protection against dust and water ingress. These certifications facilitate regulatory compliance in European markets and enable reliable operation in industrial settings with stringent cleanliness and protection requirements.

Digital control electronics reduce drift and improve repeatability, lowering scrap and rework. Fieldbus or VP-Tool interfacing reduces wiring and maintenance complexity, while easier commissioning shortens downtime. Availability of CAD data, brochures, and datasheets supports faster integration and informed procurement decisions, contributing to lower total cost of ownership over the valve’s life cycle.