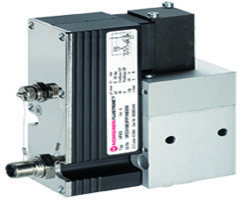

Norgren VP2316BD461MB201 Proportional Valve - IP65

Part Number: VP2316BD461MB201

Quick Summary

The Norgren VP2316BD461MB201 proportional valve provides precise pressure control for pneumatic systems in automation and packaging lines. Engineers often struggle with integrating external pressure control, digital electronics, and fieldbus interfaces in compact valve assemblies. The valve complies with CE marking and IP65 ingress protection, and supports optional fieldbus interfacing to meet industrial automation standards. Designed for reliable, digitally controlled precision in VP23 family products, it helps manufacturers reduce cycle times and downtime while ensuring CE/IP65 compliance.

Product Information

Extended Description

VP2316BD461MB201 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

7 ... 17 bar, 102 ... 247 psi

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Range

VP23

Brand

IMI Norgren

All-digital control electronics provide precise, repeatable pressure setpoints with rapid settling and simplified tuning. This improves process stability and reduces waste in sensitive applications such as automated dosing and packaging lines. Applied to compact valve assemblies in automation lines, it streamlines commissioning and minimizes calibration time while delivering consistent performance. Variable pressure control enables a single valve to adapt to different load conditions, and external pressure control on request lets you tailor system pressure to downstream actuators. The business impact is energy efficiency and reduced actuator load, which lowers energy consumption and wear. This is ideal for multi-zone pneumatic systems in packaging or material handling. Optional serial interfacing with VP-Tool and fieldbus actuation reduce wiring complexity and enable remote parameter tuning. Users can monitor pressure, adjust profiles, and perform diagnostics from a central control system, cutting commissioning time and downtime. This supports Industry 4.0 readiness and easier replacement in existing VP23-based installations. IP65-rated enclosure and CE certification ensure rugged operation in dusty or wash-down–like environments, while nitrile seals withstand typical industrial oils and temperatures. These protections translate to longer service life and lower maintenance costs in harsh factories. The combination of enclosure, seals, and certifications makes it easier to achieve regulatory compliance and safer operation. Designed for VP23 series compatibility, the valve integrates with standard air reservoirs and manifolds, simplifying installation and spare part management. The product’s compact footprint, standardized ports, and documented CAD data speed up OEM integration and field retrofits. Overall, customers gain predictable performance, reduced lifecycle costs, and a solid basis for lean manufacturing initiatives.

Get a Quick Quote for a Norgren VP2316BD461MB201

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2316BD461MB201?

Enquire Now

FAQs

To integrate the VP2316BD461MB201 with a VP23 manifold, mount the valve onto the standard manifold interface, connect the compressed air supply, and verify the low-friction seals and IP65 enclosure are properly sealed. If you plan to use serial configuration or fieldbus, enable the optional VP-Tool interface or fieldbus module and follow the configuration steps to load the correct pressure setpoints and profiles. Proper electrical connections and enclosure sealing ensure long-term reliability in industrial environments.

The valve operates between 7 and 17 bar of supply pressure and is rated for ambient temperatures from -5 to 50 °C (23 to 122 °F). It uses nitrile rubber seals suitable for standard compressed-air environments. These ranges support stable performance in most industrial pneumatic applications, including automation lines and packaging equipment, while maintaining reliability under typical factory conditions.

Yes, the VP2316BD461MB201 is designed for precise, repeatable pressure control with digital electronics that enable rapid settling and consistent actuation. Its VP23 compatibility and optional fieldbus interfaces support fast tuning and remote diagnostics, reducing startup time and downtime on high-speed lines. While exact cycle times depend on system design, the valve delivers predictable performance essential for high-throughput packaging applications.

The valve is CE certified and IP65 protected, ensuring compliance with broad European regulatory standards and robust ingress protection for dusty or wash-down-like environments. Optional fieldbus actuation and VP-Tool interfacing expand compatibility with industrial control networks, supporting safer operation and easier integration into modern automation systems.

Digital, proportional control reduces energy use by limiting pressurized air only to required levels, lowering consumption and wear on downstream actuators. Nitrile seals and a rugged IP65 enclosure extend service intervals, reducing maintenance costs. The ability to tune pressures via VP-Tool or fieldbus lowers commissioning time and improves process stability, contributing to faster ROI and improved overall equipment effectiveness.