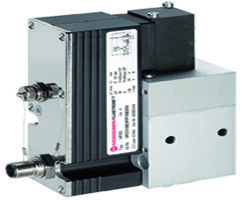

Norgren VP2316BD761MB200 Proportional Pressure Valve - IP65

Part Number: VP2316BD761MB200

Quick Summary

Norgren VP2316BD761MB200 is a proportional pressure control valve designed for precise air pressure management in automation systems. This solution addresses drift, slow start-up, and inconsistent downstream regulation that can bottleneck production lines. The unit combines all-digital control electronics with an option for external pressure control, ensuring stable performance across demanding environments. It carries CE certification and an IP65 rating, giving you confidence in compliance and ruggedness in dusty or wash-down settings. Optional VP-Tool serial interfacing and fieldbus actuation simplify networked control, reducing integration time and maintenance overhead. In practice, this valve supports higher efficiency, tighter process control, and a lower total cost of ownership for modern manufacturing lines.

Product Information

Extended Description

VP2316BD761MB200 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

0 ... 16 bar, 0 ... 232 psi

Port Size

ND8

Control Signal

0 … 10 V

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Dimensions - Height

113.3 mm

Dimensions - Length

136 mm

Dimensions - Width

55 mm

Weight

1.1 kg

Country of Origin

Czechia

Range

VP23

Brand

IMI Norgren

Feature → Business Impact → Application: Digital control electronics deliver precise, repeatable pressure regulation with fast response, enhancing line stability and reducing scrap in high-speed pneumatic lines. Application: automated assembly and packaging where consistent downstream pressure improves product quality. Feature → Business Impact → Application: External pressure control on request provides flexible system topology, enabling rapid reconfiguration for multi-zone processes without replacing hardware. Application: modular pneumatic manifolds and distributed control architectures in smart factories. Feature → Business Impact → Application: Optional VP-Tool serial interfacing and fieldbus actuation streamline integration with existing control networks, lowering commissioning time and risk. Application: OEM automation cells and plant-wide control systems. Feature → Business Impact → Application: IP65 rated enclosure and nitrile-seal reliability deliver rugged operation in dusty or wash-down environments, reducing maintenance cycles and downtime. Application: food & beverage, automotive, and general industrial automation. Feature → Business Impact → Application: ND8 port size, 0-16 bar range, and 0-10 V control enable compact installation with broad compatibility, minimizing custom adapters. Application: retrofits and new builds across existing pneumatic pipelines. Feature → Business Impact → Application: CE compliance and robust construction mitigate regulatory risk and extend service life, delivering lower total cost of ownership over the valve’s life cycle. Application: regulated manufacturing environments and multi-shift operations.

Get a Quick Quote for a Norgren VP2316BD761MB200

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2316BD761MB200?

Enquire Now

FAQs

Installation involves mounting the valve onto standard ND8 pneumatic interfaces and connecting the compressed air supply. Use nitrile-seal compatible fittings and ensure proper seal seating to maintain IP65 integrity. Electrical connections should follow the 0-10 V control scheme, and if you enable external pressure control, configure the downstream feedback path accordingly for accurate closed-loop control.

The valve accepts a 0-10 V control signal for analog proportional regulation. Optional VP-Tool serial interfacing provides a convenient method to configure and monitor valve performance, while fieldbus actuation can integrate the valve into larger automation networks, reducing wiring and simplifying diagnostics.

Yes, the VP2316BD761MB200 is IP65-rated, making it robust against dust ingress and water exposure in harsh environments. Maintenance-wise, rely on standard pneumatic checks, replace nitrile seals as part of routine service, and inspect electrical connections periodically to preserve performance and reliability in multi-shift operations.

The valve is CE-certified, confirming compliance with European safety and performance standards. IP65 provides protection against dust and water, supporting use in challenging environments. These certifications help meet regulatory requirements for many automotive, packaging, and general industrial automation applications.

You can expect reduced energy use due to precise, repeatable pressure control, leading to lower compressor load and waste. The digital electronics improve repeatability and lower process variation, while optional fieldbus interfaces shorten integration time. Overall, these factors contribute to longer mean time between failures and lower total cost of ownership in high-cycle operations.