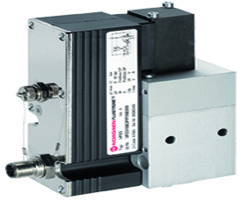

Norgren VP2316BE461MB201 Proportional Pressure Control Valve - IP65

Part Number: VP2316BE461MB201

Quick Summary

VP2316BE461MB201 is a proportional pressure control valve that delivers precise pressure control for automated pneumatic systems. Engineers often face drift and lengthy tuning when upgrading valve control in existing lines, leading to process variability. CE conformity and IP65 protection ensure safe, reliable operation in harsh factory environments. Optional VP-Tool serial interfacing and fieldbus actuation simplify integration with modern automation architectures, shortening commissioning time and reducing installation risk. Built on the VP23 family platform, it provides all-digital control electronics that support repeatable setpoints and predictable behavior across multiple applications. In manufacturing environments from packaging to robotics, this valve delivers consistent, energy-efficient pressure control while helping maintenance teams optimize uptime.

Product Information

Extended Description

VP2316BE461MB201 Norgren: All-digital control electronics | Variable pressure control, external pressure control upon request | Optional: serial interfacing with VP-Tool program | Optional actuation via fieldbus | Valve conforms to CE | Free of lacquer affecting substances

Medium

Compressed air

Operating Temperature

-5 ... 50 °C, 23 ... 122 °F

Operating Pressure

7 ... 17 bar, 102 ... 247 psi

Materials - Seals

Nitrile rubber

Certification - IP Rating

IP65

Range

VP23

Brand

IMI Norgren

All-digital control electronics deliver precise, repeatable pressure setpoints, reducing drift and improving process stability across cycles. Business impact: tighter quality, fewer off-spec events, and extended actuator life in high-speed lines. Application: automated pneumatic networks requiring dependable digital control with quick parameter updates. External pressure control upon request offers flexible zoning without sacrificing local responsiveness, enabling scalable system architectures for complex lines. Business impact: simplified cascade control and reduced hardware footprint. Application: multi-zone packaging and material-handling systems where centralized regulation is advantageous. Optional serial interfacing with VP-Tool facilitates parameterization, data logging, and fault tracing, cutting commissioning time and maintenance overhead. Business impact: faster start-ups, improved traceability, lower service downtime. Application: mixed vendor environments needing robust diagnostics. Optional fieldbus actuation reduces wiring complexity and enhances PLC interoperability, lowering installation costs and simplifying future upgrades. Business impact: streamlined integration and better diagnostics across the control loop. Application: plant-wide automation with standard fieldbus networks. IP65 rating protects against dust and water ingress, boosting reliability in demanding environments. Business impact: longer service intervals and reduced maintenance costs. Application: dusty or wet factory floors and washdown areas. Seals made from nitrile rubber withstand common industrial fluids while maintaining reliability across -5 to 50 °C. Business impact: sustained performance and lower replacement costs. Application: general-purpose compressed-air systems. VP23-range compatibility eases scaling across lines, while the compact, rugged design supports straightforward panel mounting. Business impact: faster deployment and lower downtime. Application: modular automation projects in packaging, robotics, and material handling.

Get a Quick Quote for a Norgren VP2316BE461MB201

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Norgren VP2316BE461MB201?

Enquire Now

FAQs

Plan for a stable panel mount and proper orientation to ensure reliable operation. Verify supply pressure stays within 7-17 bar and provide clean, dry compressed air to protect seals. If external pressure control is used, ensure compatibility with VP23 family guidelines and maintain IP65 protection throughout the installation. Use VP-Tool or fieldbus interfaces where appropriate to simplify diagnostics and commissioning.

Key specs include medium: compressed air; operating temperature range -5 to 50 °C; operating pressure range 7-17 bar; seals: nitrile rubber; IP65 ingress protection; range VP23; digital control electronics; optional serial VP-Tool interfacing and fieldbus actuation for broader interoperability.

Yes. The valve offers optional fieldbus actuation and serial interfacing via VP-Tool, enabling easier parameterization, data logging, and fault tracing. This compatibility reduces wiring, simplifies PLC integration, and accelerates commissioning in modern automation architectures such as packaging lines and robotic cells.

The valve carries CE conformity for safety and performance compliance and IP65 rating for protection against dust and water ingress. These certifications support safe operation in typical factory environments and simplify regulatory alignment for industrial pneumatic systems that must meet European standards and rugged use cases.

Its all-digital control electronics deliver repeatable performance, reducing drift and rework. Optional VP-Tool and fieldbus interfaces shorten commissioning and enable easier diagnostics, cutting downtime. Rugged IP65 protection and nitrile seals extend service intervals, lowering maintenance costs while enabling scalable VP23-based deployments across multiple production lines.