Rittal VX 5051.250 Roof Plate - Zinc-Plated Steel

Part Number: 5051250

Manufacturer

Rittal

Part number

5051250

Category

Alt Part Number

VX 5051.250

Quick Summary

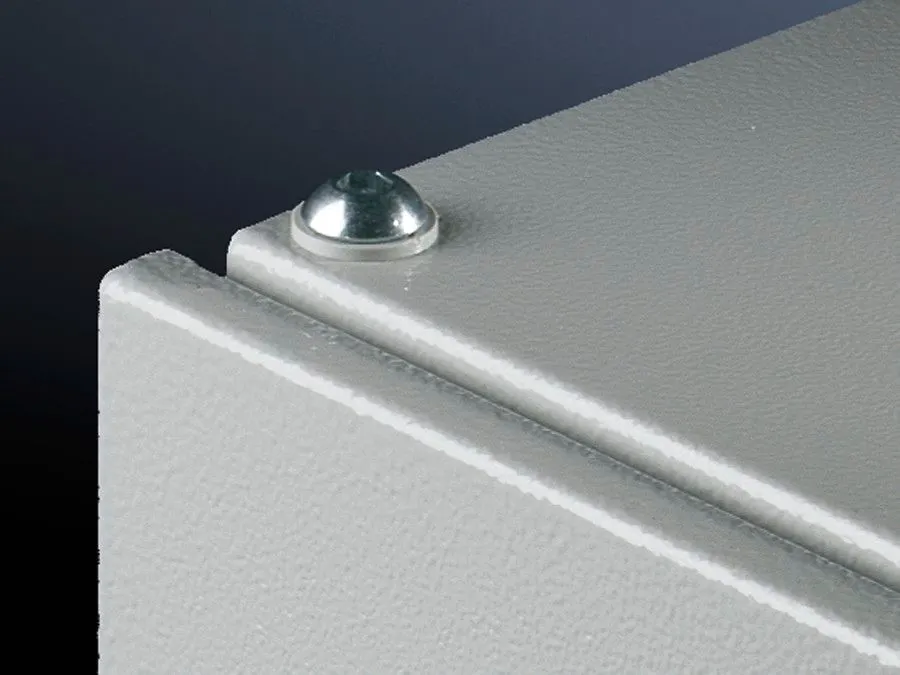

The Rittal VX 5051.250 roof plate enables secure screw-fastened roof mounting for enclosure roofs. Eyebolts and grommets often complicate grounding and slow installation; this accessory uses contact washers for potential equalisation to simplify wiring and improve reliability. While the data sheet notes steel with a zinc-plated finish, and standard M12 threads, engineers should consider CE marking, IP ratings, and SIL safety requirements when integrating this component into a larger system. Your decision should factor in enclosure certification and environmental exposure. For business value, the solution offers faster installation, robust corrosion resistance, and reliable grounding, supporting consistent electrical safety and lower maintenance costs in industrial control panels and automation cabinets.

Product Information

Article number

VX 5051.250

Material

Steel

Surface finish

zinc-plated

Supply includes

20 pan head screws M12 x 20, hex socket | 20 serrated sealing washers A 12.5

Dimensions

Thread: M12

Packs of

20 pc(s).

Weight/pack

0.54 kg

Customs tariff number

73181900

EAN

4028177972230

Feature: Steel construction with zinc-plated finish provides durable, corrosion-resistant mounting for enclosure roofs. Business impact: Prolongs service life in harsh industrial environments and reduces maintenance. Application: Suitable for industrial enclosures and control cabinets where long-term reliability is essential. Feature: Screw-fastening design with included M12 x 20 pan head screws and serrated washers improves installation speed and sealing integrity. Business impact: Shortens assembly time, lowers labor costs, and enhances gasket performance during roof mounting. Application: Assembly lines and retrofit projects aiming for fast, repeatable roof fastening. Feature: Integrated contact washers enable potential equalisation for grounding and EMI control. Business impact: Improves electrical continuity and reduces ground-loop risk. Application: Electrical cabinets and automation panels requiring dependable grounding. Feature: Thread compatibility with M12 mounting and a 20-piece pack format supports predictable sourcing. Business impact: Simplifies inventory planning and ensures consistent torque and fit. Application: Stocking for maintenance teams and OEMs. Feature: Ready-to-install packaging with clear dimensions and EAN for traceability. Business impact: Reduces ordering errors and speeds procurement. Application: Fleet deployments and procurement workflows across industrial facilities.

Get a Quick Quote for a Rittal 5051250

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 5051250?

Enquire Now

FAQs

Install by aligning the plate with the enclosure roof bolts and threading M12 fasteners through the plate using the supplied pan head screws. Tighten securely with a hex socket, ensuring the included serrated washers establish proper sealing and grounding. Use the contact washers for potential equalisation where a reliable electrical path is required.

The kit includes 20 pan head screws M12 x 20 with a hex socket and 20 serrated sealing washers A12.5, designed to fit the M12 thread and provide a secure, sealed mounting for the roof plate.

Yes, the plate uses M12 threading. The package specifies packs of 20 with a thread specification of M12; the weight per pack is 0.54 kg, and the supply includes 20 screws and 20 washers.

It includes contact washers for potential equalisation, improving electrical continuity and helping to mitigate ground-loop issues, which supports more reliable grounding and EMI performance in enclosure assemblies.

The roof plate features steel construction with a zinc-plated finish for corrosion resistance. This combination is well-suited for industrial enclosure applications where durability and long service life are important, though ensure compatibility with your specific environmental IP/CE/SIL requirements.