Rittal AS 5051.587 Wear plate - Perforex LC fit

Part Number: 5051587

Manufacturer

Rittal

Part number

5051587

Category

Alt Part Number

AS 5051.587

Quick Summary

Wear plate for workpiece support protects machine beds and stabilizes workpieces in Perforex LC applications. Without a robust wear plate, production downtime rises due to bed wear and misaligned tooling, slowing throughput. Industry expectations for tooling interfaces in automation and control systems include reliable safety considerations, durable enclosure protection, and long service life to lower maintenance costs and downtime. Leveraging this wear plate set helps engineers optimize asset utilization, reduce spare-part inventories, and streamline installation within existing automation architectures.

Product Information

Extended Description

5051587 Rittal: Wear plate, workpiece support up to machine number 620-039

Article number

AS 5051.587

Supply includes

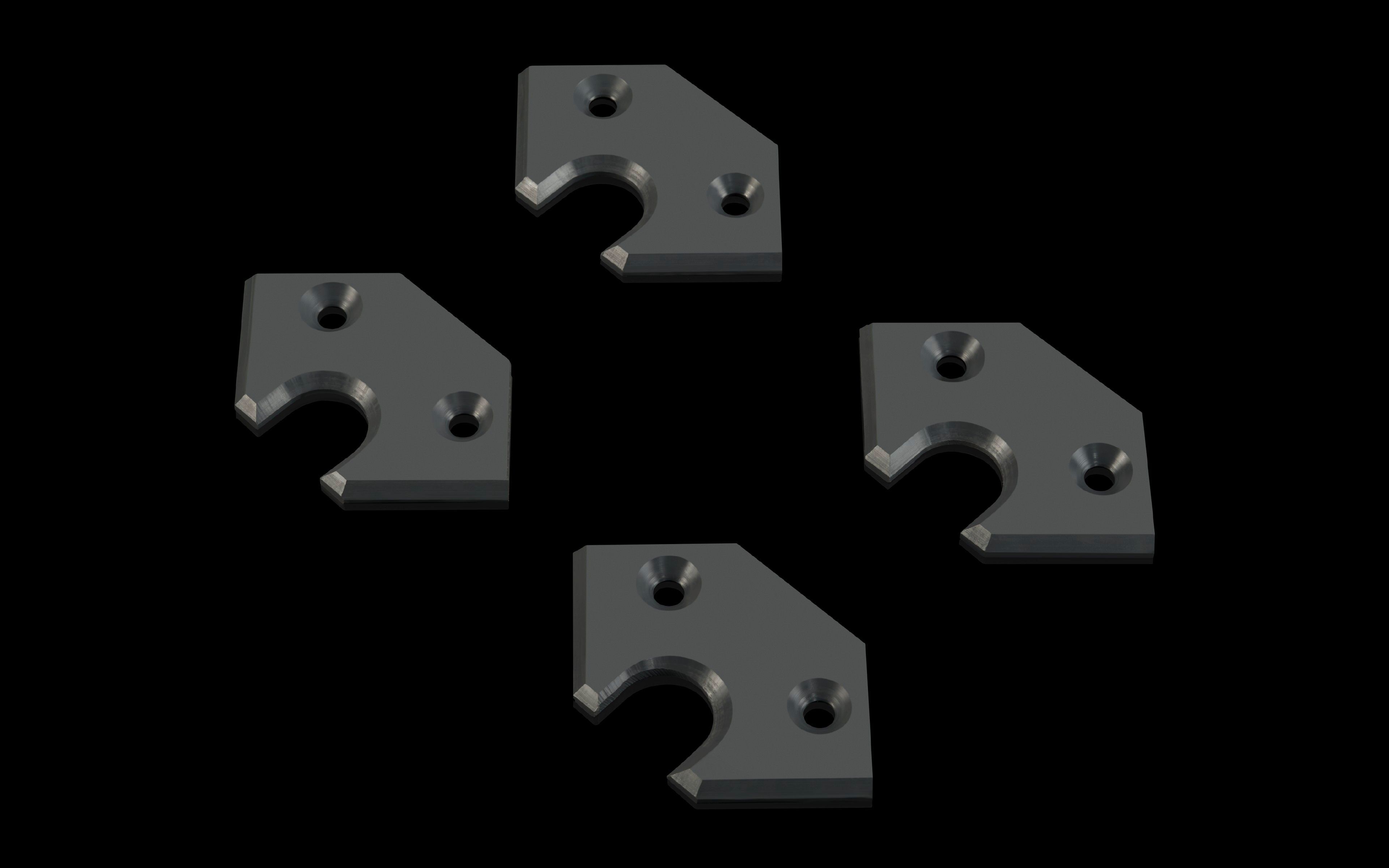

4 wear plates

To fit

Perforex LC up to machine number 620-039

Customs tariff number

39269097

EAN

4028177954090

Product description

Wear plate, workpiece support up to machine number 620-039

Feature → Business Impact → Application: The AS 5051.587 kit includes four wear plates, delivering immediate uptime benefits by reducing bed wear and scrap while extending the service life of the machine bed. This translates to lower maintenance costs and higher line throughput for Perforex LC operations, especially in high-volume production environments where precision and repeatability are critical. Application-wise, it directly supports workpiece accuracy and repeatable positioning during machining campaigns, improving overall part quality and process reliability. Feature → Business Impact → Application: Compatibility with Perforex LC up to machine number 620-039 ensures a clean retrofit path and minimizes integration risk, reducing downtime during changeovers and speeding up tool-change cycles. This is particularly valuable for contract manufacturers and shop floors needing quick turnarounds without compromising accuracy. Application-wise, the wear plates align with existing interface tolerances, enabling straightforward installation and predictable wear patterns across the tooling station. Feature → Business Impact → Application: Supplied as a 4-piece set, the wear plates simplify inventory management and spare-part planning, lowering stockholding costs and simplifying reordering during maintenance windows. Application-wise, maintenance windows become more efficient, with rapid replacement reducing production gaps. Feature → Business Impact → Application: The design emphasizes stable workpiece support and bed protection, improving clamping reliability and reducing chatter in Perforex LC workflows. Application-wise, this supports demanding milling and finishing tasks where surface integrity and dimensional stability are paramount. Feature → Business Impact → Application: The kit ecosystem aligns with standard automation component practices, enabling smoother procurement and interoperability with other Rittal or partner devices. Application-wise, it reduces vendor footprint and accelerates project timelines across automation upgrades, retrofits, or new line deployments.

Get a Quick Quote for a Rittal 5051587

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 5051587?

Enquire Now

FAQs

Begin by verifying compatibility with Perforex LC and machine 620-039. Remove the existing bed wear components, align the new wear plates to the mounting pattern, and secure with the original fasteners. After installation, check for proper seating and confirm that your workpiece surfaces register consistently. This minimizes setup time and reduces run-out during initial cycles.

The four-plate kit provides immediate bed protection, reducing wear-related downtime and scrap. This yields improved dimensional stability and accuracy in workpiece handling, better clash-free toolpaths, and lower maintenance costs over the system’s life. The fit and repeatability support higher line throughput in Perforex LC workflows.

Yes. The AS 5051.587 wear plates are designed to fit Perforex LC systems up to machine number 620-039, delivering a straightforward retrofit with minimal configuration changes. This compatibility helps maintain existing fixtures and control logic while upgrading wear resistance.

While this data set does not specify formal certifications for the kit, industrial wear plates used in automation typically align with broad safety and interoperability expectations. Users should verify local CE/UKCA labeling, IP enclosure ratings, and supplier documentation during procurement to ensure compliance for their specific application and environment.

ROI improves through reduced bed wear, fewer part rejections due to misalignment, and faster changeovers. The four-plate kit lowers spare-parts spend and extends tool life by stabilizing workpiece positioning, enabling higher uptime and consistent part quality across production runs.