Rittal VX 5302.028 Potential Equalisation Kit - UL Approved

Part Number: 5302028

Quick Summary

Rittal VX 5302.028 Potential Equalisation Kit enables central potential equalisation for VX IT enclosures to improve EMC. This reduces EMI risks associated with scattered bonding points and inconsistent earthing, addressing a common challenge for panel builders and maintenance teams. UL approvals support safe, regulator-aligned installations and simplify audits across manufacturing environments. The Plus version provides a pre-sized rail and six M8, 16 mm² earthing braids designed for VX IT enclosures between 1800 and 2000 mm in height, with assembly parts included for quick commissioning. For modernization projects, this solution offers predictable maintenance intervals and reduced field rework, delivering reliable bonding without sacrificing installation speed.

Product Information

Extended Description

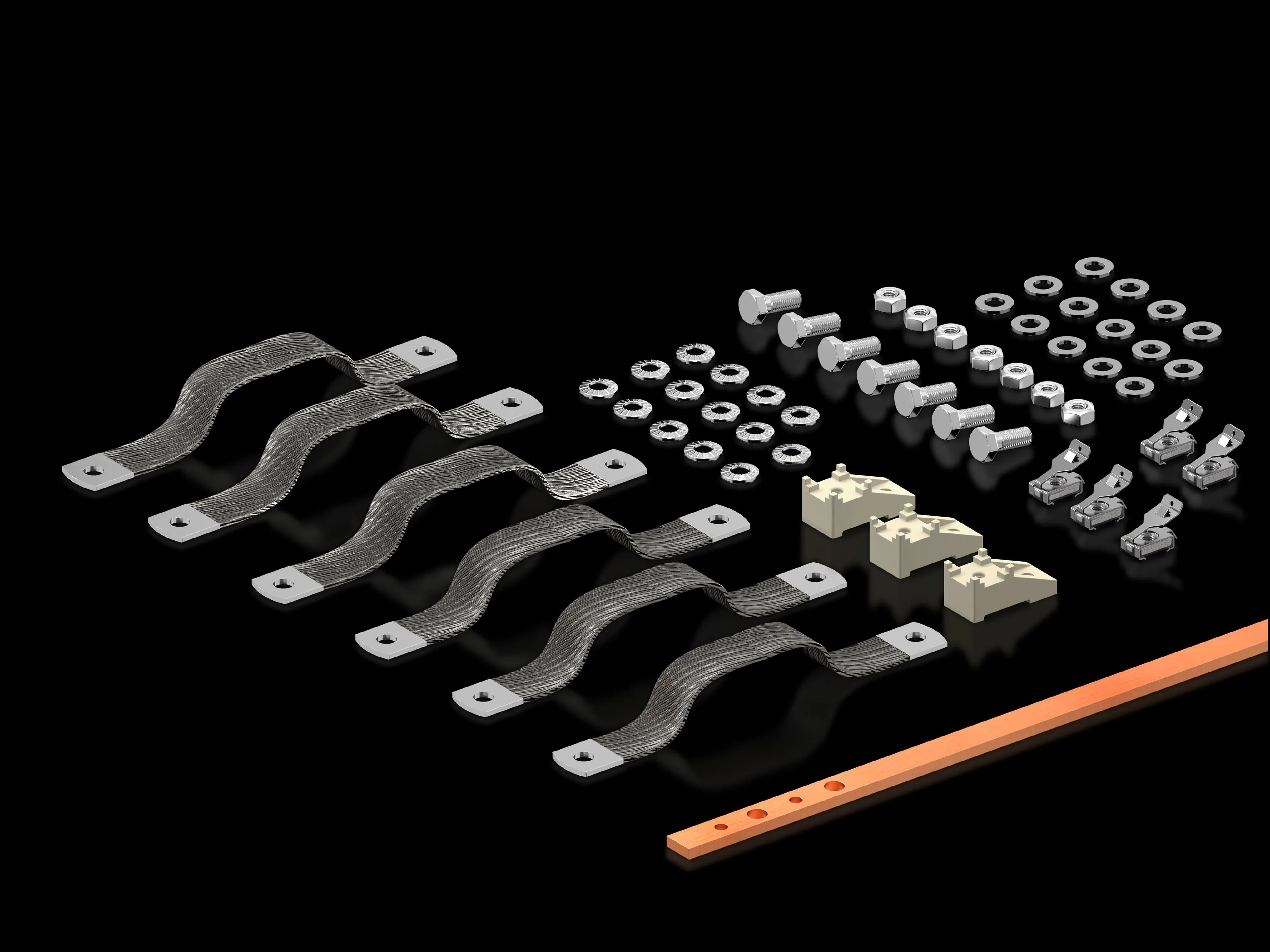

5302028 Rittal: Potential equalisation kit, Plus version, for VX IT, for improved EMC. Potential equalisation rail for central potential equalisation of all installed equipment on the enclosure and components connected to the potential equalisation, 6 earthing braids (M8), 16 mm², for sheet steel doors, side panels, potential equalisation rail, length 1545 mm, for height 1800 – 2000 mm, incl. assembly parts, approvals: UL

Article number

VX 5302.028

Product description

For improved EMC.

Benefits

All enclosure elements are connected via earthing braids to a central, vertical potential equalisation rail (rack bonding busbar, RBB) via the frame structure as central consolidation point

Applications

Ensures continuous potential equalisation and/or functional earthing

Function principle

Potential equalisation rail for central potential equalisation of all installed equipment on the enclosure and components connected to the potential equalisation

Supply includes

6 earthing braids (M8), 16 mm², for sheet steel doors, side panels, potential equalisation rail | Potential equalisation rail, length 1545 mm, for height 1800 – 2000 mm | Assembly parts

Assembly instruction

The specific connection cables between the installed equipment and the potential equalisation rail must be supplied by the user

Note

If a risk assessment of the ultimate application has been carried out by a qualified electrician and no extended risk potential has been identified, no protective earthing measures are required

Packs of

1 pc(s).

Weight/pack

1.066 kg

Customs tariff number

73269098

EAN

4028177955349

ETIM 9

EC001503

ECLASS 8.0

27149219

Product description

Potential equalisation kit, Plus version, for VX IT, for improved EMC. Potential equalisation rail for central potential equalisation of all installed equipment on the enclosure and components connected to the potential equalisation, 6 earthing braids (M8), 16 mm², for sheet steel doors, side panels, potential equalisation rail, length 1545 mm, for height 1800 – 2000 mm, incl. assembly parts, approvals: UL

Central potential equalisation rail provides a single consolidation point for all bonding connections, enabling continuous potential equalisation across the enclosure frame and connected equipment. The business impact is a measurable reduction in EMI risk, with fewer stray currents and more predictable functional earthing across the panel, which speeds commissioning and testing. This approach is ideal for VX IT enclosures in industrial automation—especially cabinets within the 1800–2000 mm height range—where a vertical, rack-bonding busbar ensures reliable bonding across the full height of the installation. Six earthing braids (M8), 16 mm², are supplied for sheet steel doors and side panels to guarantee uniform coverage. The business impact is faster, more repeatable installation with fewer improvised bonding solutions, reducing field errors and warranty incursions. This kit is designed for rack-integrated systems and can be integrated with existing frame structures to keep the bonding path central and accessible during maintenance. Rail length of 1545 mm and included assembly parts align with VX IT cabinets in the 1800–2000 mm height band, reducing on-site cutting and compatibility issues. The installation remains straightforward with assembly parts—reducing the risk of incorrect mounting or missing components. Note on cables: The specific connection cables between installed equipment and the potential equalisation rail must be supplied by the user, ensuring compatibility with existing equipment and cabling strategies. UL approvals provide a safety and compliance signal for system integrators, while the kit’s compact weight (1.066 kg per pack) and modular design simplify logistics, field retrofits, and ongoing maintenance.

Get a Quick Quote for a Rittal 5302028

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 5302028?

Enquire Now

FAQs

Installation starts with mounting the potential equalisation rail along the enclosure frame, followed by securing the six M8 earthing braids to the doors and side panels as specified. The rail length of 1545 mm is designed for 1800–2000 mm tall VX IT cabinets, and assembly parts are included for a straightforward, repeatable fit. The user must supply the connection cables from installed equipment to the rail to complete the bonding path.

Key specs include six M8 earthing braids with 16 mm² cross-section, a 1545 mm long potential equalisation rail, suitable for VX IT enclosures between 1800 and 2000 mm in height, and UL approvals. The package weight is 1.066 kg per pack, and the kit is supplied with assembly parts and documentation for compliance and traceability.

This kit is specifically designed for VX IT enclosures and is optimized for the 1800–2000 mm height range. While it provides a robust central bonding path for VX IT, compatibility with non-VX IT brands or models should be verified against system bonding requirements and rail mounting geometry before use.

UL approvals indicate compliance with safety requirements for electrical installations. The assembly note states that specific connection cables between installed equipment and the potential equalisation rail must be supplied by the user, enabling custom integration with existing wiring practices and risk assessments performed by a qualified electrician.

By consolidating bonding points into a central rail, EMI risk is reduced and commissioning time decreases due to a repeatable, documented bonding path. Ongoing maintenance becomes simpler because the central rail and braids provide a predictable, inspectable bonding scheme, lowering the likelihood of bond failures and rework during service windows.