Rittal VX 5304.126 VX IT Enclosure - IK08 Rating

Part Number: 5304126

Quick Summary

Rittal VX 5304.126 VX IT enclosure provides climate-controlled housing for industrial IT equipment in demanding environments. Engineers often contend with heat buildup, restricted cable routing, and limited service access in tight control rooms. This enclosure delivers IK08 impact protection and UL 2416 load compliance, supporting reliable operation in harsh factories, data centers, and manufacturing facilities. The standard 24 U layout with 19-inch mounting angles, front and rear access, and a glazed front door offers flexible installation, easy maintenance, and scalable IT deployment. By combining robust construction with precise steel and aluminum components, it enables compliant, long-term IT enclosure performance that reduces downtime and lifecycle costs in automation networks.

Product Information

Extended Description

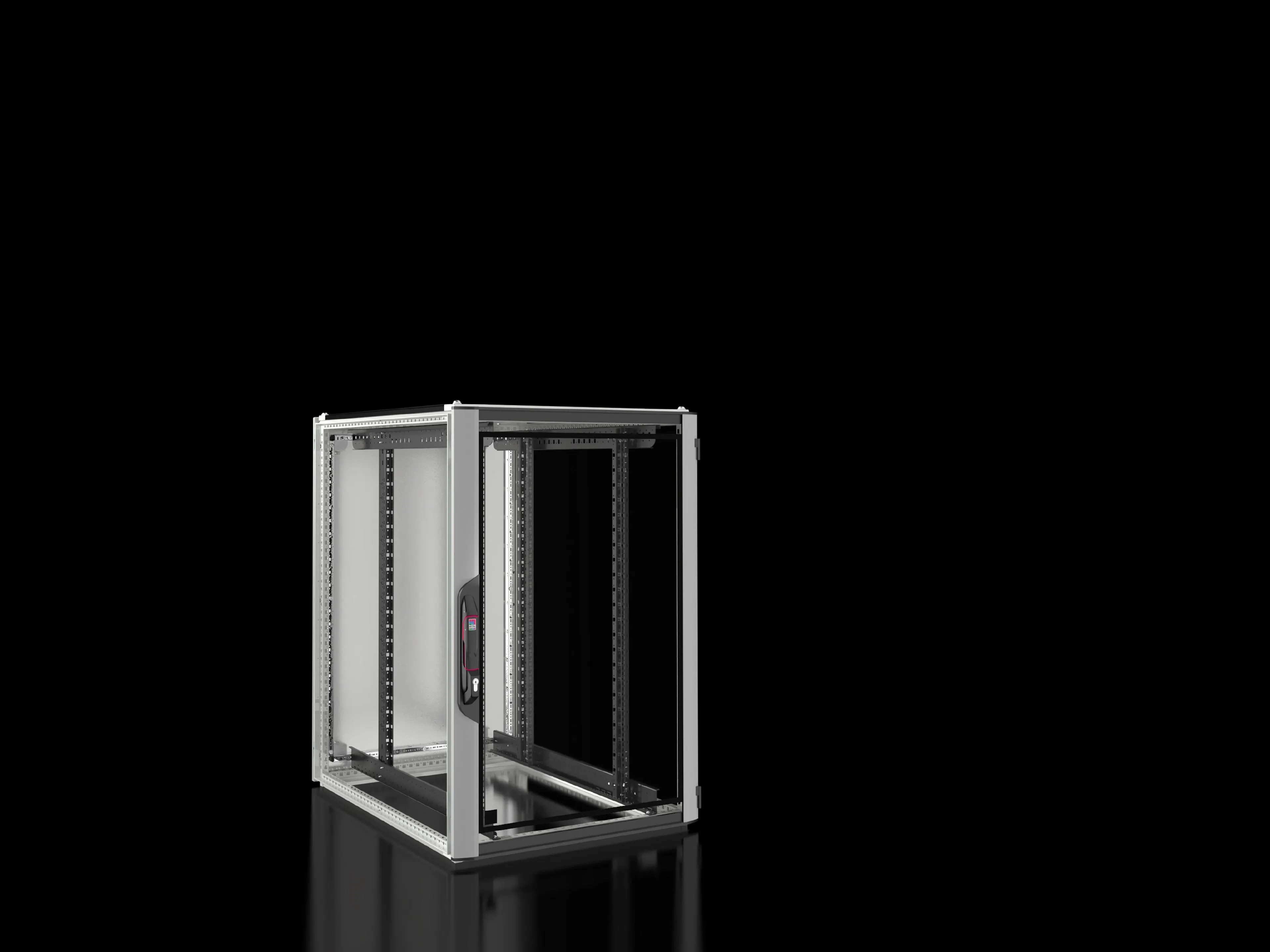

5304126 Rittal: VX IT, 19" mounting angles, standard, front and rear, glazed door, WHD: 800 x 1200 x 1000 mm, 24 U

Article number

VX 5304.126

Material

Sheet steel | Aluminium | Glazed door: Single-pane safety glass, 3 mm

Surface finish

Enclosure frame: Dipcoat-primed | Interior installation: Spray-finished | Rear door and roof: Dipcoat-primed, powder-coated | Front door: Aluminium, anodised/spray-finished

General colour

RAL 7035

Colour

Enclosure frame, rear door and roof: RAL 7035 | Front door: Vertical sections, silver coloured and horizontal sections, RAL 9005 | Interior installation: RAL 9005 | Handle and hinges: RAL 9005

Supply includes

VX enclosure frame with doors and roof plate | Glazed aluminium door at the front, 180° hinges | Lock front and rear: Comfort handle for profile half-cylinders and security lock 3524 E | Mounting angles, 482.6 mm (19") | Spacers, height 50 mm, to raise a cover plate above the fan cut-out in the roof plate, for passive cooling (supplied loose). Not required for variants without a cut-out. | 12 x 482.6 mm (19") fastener, 1 U, conductive (supplied loose) | 25 multi-tooth screws, conductive (supplied loose) | IPPC pallet | Roof plate, multi-piece, with side cable entry in the depth, double-sided, prepared for fan mounting plate | Sheet steel rear door, solid, one-piece, 130° hinges

Dimensions

Width: 800 mm | Height: 1,200 mm | Depth: 1,000 mm

Units

24 U

Units

24 U

Free mounting space to the 482.6 mm (19") level, front/rear

87 mm / 193 mm

Mounting position of the 482.6 mm (19") level

front and rear

Distance between levels as delivered

720 mm

482.6 mm (19") attachment

on depth stays, screw-fastened at the top and bottom

Design

Standard

Roof design

multi-piece, with side cable entry in the depth, double-sided, prepared for fan mounting plate

Rear door design

Sheet steel door, solid, one-piece, 130° hinges

Front door design

Glazed aluminium door, solid, one-piece, 180° hinges

Mounting angle design

482.6 mm (19") mounting angles, standard in the VX IT

Base design

Open

482.6 mm (19") level(s) version

front and rear

Mounting angles position

482.6 mm (19") level, front and rear

Load capacity

15,000 N

Max. load capacity (static) per enclosure to UL 2416

12,000 N

IK Code

IK08

Note

Depending on how and where it is sited, the door opening angle may vary for selected applications

Basic material

Sheet steel

Packs of

1 pc(s).

Weight/pack

87.4 kg

PCF per pack (cradle-to-gate)

215.3 kg CO2 eq (Cat B)

Note on PCF category

Category B: PCF value (cradle-to-gate) based on the product weight, approximately calculated and self-declared

EAN

4028177944893

ETIM 7.0

EC002499

ECLASS 8.0

27180207

Product description

VX IT, 19" mounting angles, standard, front and rear, glazed door, WHD: 800 x 1200 x 1000 mm, 24 U

Feature → Business Impact → Application: The VX IT enclosure provides 24 U of mounting space with 19" mounting angles (482.6 mm) front and rear, enabling rapid IT rack deployments and standardized equipment fitment across automation networks. This translates to faster project timelines, reduced commissioning risk, and improved cable management for scalable industrial IT setups. Application-wise, it suits dense control cabinets and data-hungry network racks in factory floors where reliability matters. Feature → Business Impact → Application: A glazed aluminium front door with vertical sections and a robust sheet-steel rear door offers clear visibility and solid protection, delivering heightened security without compromising access. This supports quick maintenance cycles and minimizes device exposure during service in manufacturing environments. Application-wise, it is ideal for visual monitoring of critical IT gear in control rooms and data centers. Feature → Business Impact → Application: The roof plate is prepared for a fan mounting plate with side cable entry and spacers to elevate a cover plate for passive cooling, reducing energy use by supporting passive cooling strategies and lowering fan-related maintenance. Application-wise, it enables optimized thermal management for dense IT loads in automated systems. Feature → Business Impact → Application: A load capacity of up to 15,000 N (12,000 N static per UL 2416) and IK08 protection deliver rugged mechanical resilience, minimizing unplanned downtime due to equipment misalignment or impact on the factory floor. This is particularly valuable for remote installations or floor-mounted cabinets in industrial environments. Application-wise, it supports robust protection for critical IT infrastructure in manufacturing, oil & gas, and process automation. Feature → Business Impact → Application: Comprehensive supply includes mounting angles, spares for passive cooling, screws, and a durable roof plate, simplifying installation logistics and reducing on-site procurement needs. This makes deployment faster and more cost-effective for system integrators and OEMs. Application-wise, it streamlines project handoffs and long-term maintenance planning in automation projects. The enclosure uses standard dimensions and finishes (W 800 mm x H 1200 mm x D 1000 mm; 24 U; RAL 7035 frame; front door in RAL 9005 accents) to ensure compatibility with a wide range of industrial IT equipment and accessories.

Get a Quick Quote for a Rittal 5304126

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 5304126?

Enquire Now

FAQs

The VX IT enclosure includes standard 19" mounting angles (482.6 mm) placed front and rear, enabling flexible, class-leading rack mounting for 24U of IT equipment. It supports front and rear access, allowing straightforward pull-out and maintenance without repositioning the cabinet. This facilitates quick upgrades and scalable IT configurations in automation projects.

The roof plate is multi-piece and prepared for a fan mounting plate, with spacers (50 mm) to raise a cover plate above the fan cut-out for passive cooling. This design reduces energy consumption by enabling passive or hybrid cooling strategies while maintaining airflow to IT gear. Installation includes necessary screws and spacers to simplify setup.

Yes. It offers IK08 impact protection and a sturdy sheet steel frame, with a glazed front door and robust rear door design. The unit supports high mechanical durability and is designed for industrial environments, making it suitable for factory floors, control rooms, and automated line cabinets where reliability and protection are critical.

Key ratings include IK08 for mechanical impact protection and UL 2416-compliant load performance, ensuring safe, durable operation under industrial loads. These certifications help ensure regulatory alignment for rugged environments and long-term equipment protection in automation and data-center-adjacent applications.

The enclosure reduces downtime by protecting IT gear in harsh environments, supports faster deployment with included mounting hardware and accessories, and enables efficient maintenance due to front/rear access and a glazed viewing door. Long-term, this translates to lower maintenance costs, predictable performance, and higher system uptime in automation and manufacturing IT deployments.