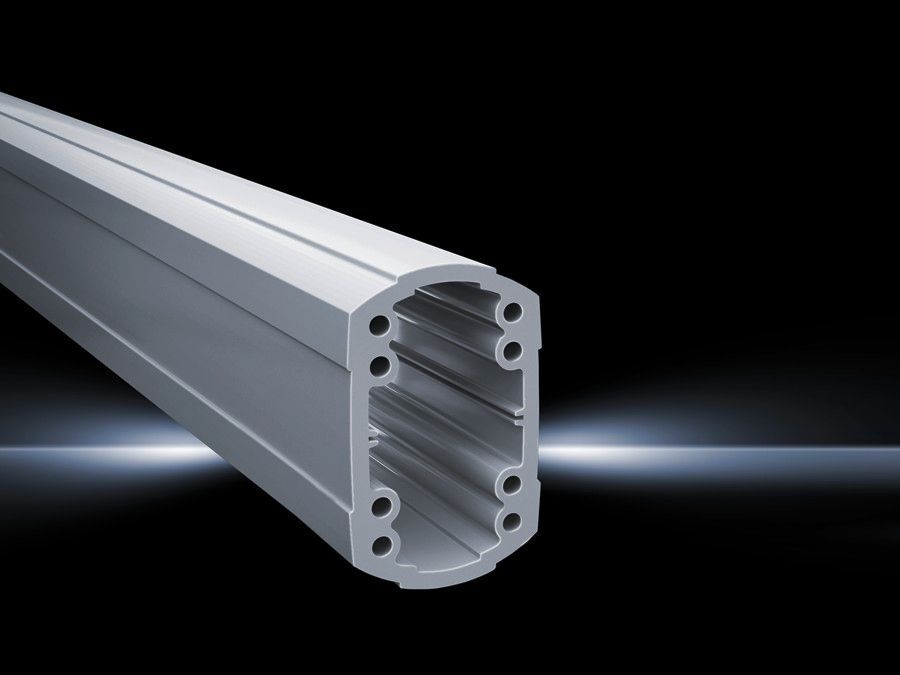

Rittal CP 6212.050 CP Support Section - 500 mm Length

Part Number: 6212050

Manufacturer

Rittal

Part number

6212050

Alt Part Number

CP 6212.050

Quick Summary

Rittal CP 6212.050 CP Support Section provides solid aluminium cable routing support for enclosure systems. It can be cut to any required length without thread tapping, reducing on-site modification time and trapping fewer delays during installation. While not all data lists formal CE or IP certifications, it aligns with ETIM EC000882 and ECLASS 27400556 standards, supporting consistent procurement and cross-system compatibility. The CP 120 solid support section is designed for modular enclosures, delivering reliable performance and straightforward integration with existing CP components. By standardizing material and finish in RAL 7035, it also minimizes color mismatch and simplifies warehouse stocking, enabling faster project startup and lower total cost of ownership.

Product Information

Extended Description

6212050 Rittal: CP Support section CP 120, solid, L: 500 mm

Article number

CP 6212.050

Product description

Attachment to the connection components with 4 self-tapping screws in the screw channel. May be cut to any required length, no thread-tapping required. Closed cable duct with a large cross-section.

Material

Support section: Extruded aluminium section

Colour

Support section: RAL 7035

Supply includes

Support section

Length

500 mm

Dimensions

Width: 75 mm | Height: 120 mm | Length: 500 mm

Packs of

1 pc(s).

Weight/pack

3.9 kg

Customs tariff number

76042100

EAN

4028177683938

ETIM 9

EC000882

ECLASS 8.0

27400556

Product description

CP Support section CP 120, solid, L: 500 mm

Feature one: Extruded aluminium construction provides high strength-to-weight ratio, enabling robust cable support without adding unnecessary weight to the enclosure. Business impact: easier handling, reduced structural strain, and lower shipping costs. Application: ideal for CP 120 and similar CP family enclosures where internal ducting and tidy cable routing are required. Feature two: Length can be cut to the exact site requirement with no thread tapping needed, saving installation time and minimizing error margins. Business impact: faster assembly, fewer field modifications, and improved project timelines. Application: optimal during retrofit or new builds in compact control panels. Feature three: Large cross-section closed cable duct supports more cables and larger power runs while maintaining organization. Business impact: improved thermal management through clear cable paths and reduced risk of interference. Application: retrofit projects in industrial automation cabinets. Feature four: Precise dimensions 75 x 120 x 500 mm and RAL 7035 finish provide consistent fit and color coordination. Business impact: reduces mismatch issues and simplifies inventory. Application: standard enclosure stocking for industrial facilities.

Get a Quick Quote for a Rittal 6212050

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 6212050?

Enquire Now

FAQs

Install by aligning the support section in the enclosure channel and fastening with four self-tapping screws in the screw channel. The piece is cut to length on site, eliminating thread tapping and enabling rapid adaptation to panel height and internal spacing.

Dimensions are 75 mm width, 120 mm height, and 500 mm length. Each pack weighs 3.9 kg and contains one CP Support section made from extruded aluminium, finished in RAL 7035.

Yes. The closed cable duct design with a large cross-section supports dense cabling while maintaining organization, improving airflow and reducing wiring errors inside control cabinets.

The specification aligns with ETIM 9 EC000882 and ECLASS 8.0 27400556, which supports consistent procurement data and integration across supplier catalogs, though explicit CE/IP certifications are not listed in the provided data.

Time savings from on-site cutting without thread tapping, simplified installation, and durable aluminium construction contribute to lower labor costs and longer service life, reducing maintenance overhead and accelerating project timelines.