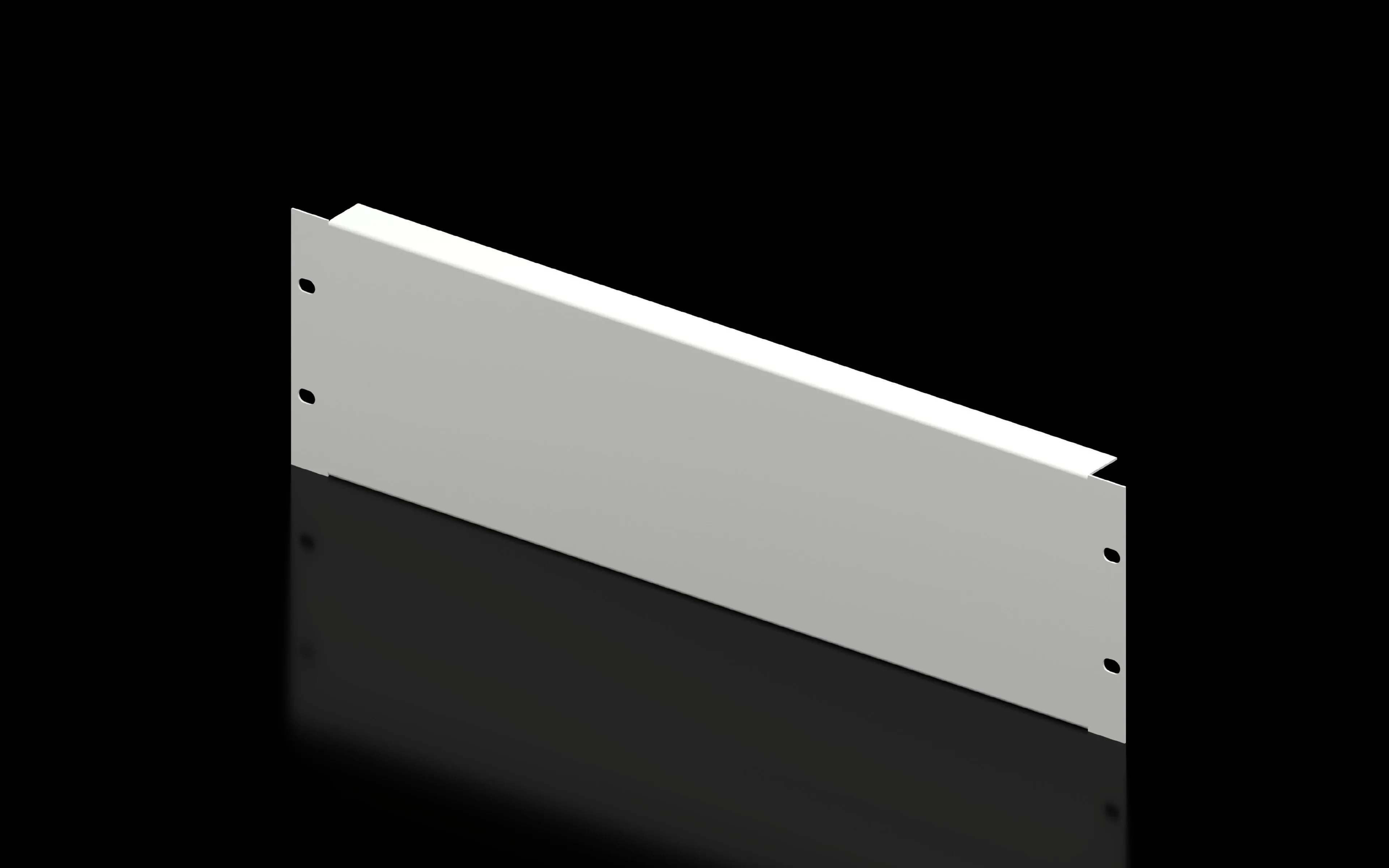

Rittal 7153035 DK Blanking Panel - 3U, RAL 7035

Part Number: 7153035

Quick Summary

DK Blanking panel is used as an extension cover or for population as required in 19" racks. This solution helps seal unused spaces, reducing ingress of dust and improving controlled airflow in enclosures. ETIM EC000456 and ECLASS 27189217 classifications provide clear compatibility and installation guidance for industrial automation cabinets. In practice, this blanking panel supports neat, compliant control cabinets, enabling efficient maintenance and streamlined enclosure population within data centers and manufacturing facilities.

Product Information

Extended Description

7153035 Rittal: DK Blanking panel, 482.6 mm (19"), 3 U, Installation height: 132,5 mm, RAL 7035

Article number

DK 7153.035

Product description

As an extension cover or for population as required.

Material

Sheet steel

Colour

RAL 7035

Build-up height

132.5 mm

Dimensions

Width: 482.6 mm

Units

3 U

Packs of

2 pc(s).

Weight/pack

1.752 kg

PCF per pack (cradle-to-gate)

6.7 kg CO2 eq (Cat B)

Note on PCF category

Category B: PCF value (cradle-to-gate) based on the product weight, approximately calculated and self-declared

Customs tariff number

94039910

EAN

4028177165762

ETIM 9

EC000456

ECLASS 8.0

27189217

Product description

DK Blanking panel, 482.6 mm (19"), 3 U, Installation height: 132,5 mm, RAL 7035

The DK Blanking panel combines robust sheet steel construction with a precise 482.6 mm width to fit standard 19" enclosures, delivering a stable, long-lasting blanking solution that minimizes dust intrusion and improves airflow management. The 3 U build and installation height of 132.5 mm ensure quick, predictable mounting in space-constrained panels, while the RAL 7035 finish provides a durable, consistent appearance across equipment racks, supporting professional, maintenance-friendly automation environments. Packaging in packs of two (weight per pack 1.752 kg) reduces logistical handling and supports scalable cabinet population. Its sustainability footprint (PCF 6.7 kg CO2 eq per pack, Category B) aligns with responsible manufacturing goals, helping you meet internal goals for green engineering. The DK 7153.035 is compatible with standard 19" enclosures and integrates smoothly with existing mounting schemes, reducing retrofit time and supporting safer, cleaner installations in industrial automation and control cabinets.

Get a Quick Quote for a Rittal 7153035

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 7153035?

Enquire Now

FAQs

To install, align the blanking panel with the 19-inch mounting rails inside the enclosure, slide it into place, and secure using the existing mounting hardware. The 3U height matches standard 19-inch rack spacing, and the 482.6 mm width ensures a snug fit without interfering with adjacent components. Ensure the enclosure is de-energized during installation and verify that the panel sits flush to prevent dust ingress.

Key specs include a 482.6 mm width, 3U unit height, installation height of 132.5 mm, and a sheet steel body finished in RAL 7035. It ships in packs of two with a weight of 1.752 kg per pack. The product is linked to ETIM EC000456 and ECLASS 27189217 classifications, aligning with standard enclosure components.

Yes. Designed for 19" enclosures, the DK 7153.035 blanking panel provides a clean, dust-resistant fill for unused slots, improving airflow and EMI containment in industrial automation control cabinets. Its robust steel construction and standard 3U height make it compatible with common enclosure designs used in automation and manufacturing facilities.

The DK 7153.035 is classified under ETIM 9 EC000456 and ECLASS 8.0 27189217, confirming its function as a blanking panel for 19" enclosures and its compatibility with related enclosure components. The PCF data indicates a Category B cradle-to-gate CO2 footprint, supporting sustainability reporting in procurement.

While price varies by supplier, the DK 7153.035 reduces maintenance and energy costs by improving airflow and dust control, which can lower cooling loads and extend component life. Its two-pack packaging reduces logistics and replacement costs, and its standardized fit shortens assembly time, delivering tangible efficiency gains for ongoing cabinet maintenance and uptime.