Rittal DK 7963.310 Slide Rail - 800 N Static Load

Part Number: 7963310

Quick Summary

Rittal DK 7963.310 is a slide rail system that enables secure mounting between the front and rear 19-inch levels in TE and EL enclosures. This design addresses common challenges with misalignment, uneven load distribution, and lengthy installation when retrofitting heavy components. It aligns with ETIM EC002620 and ECLASS 27189261 standards, supporting seamless cataloging and procurement, while the EAN 4028177443938 anchors traceability. Although formal CE certification and IP ratings are typically confirmed by the component supplier for enclosure hardware, this rail's zinc-plated sheet steel construction offers durable performance in demanding industrial environments. In practice, teams gain faster, more reliable installs, consistent fit, and improved maintenance workflows for modular 19-inch systems.

Product Information

Extended Description

7963310 Rittal: DK Slide rail, support surface WxD: 85x324 mm, 80 kg, static, distance between levels:: 395 mm, For TE

Article number

DK 7963.310

Product description

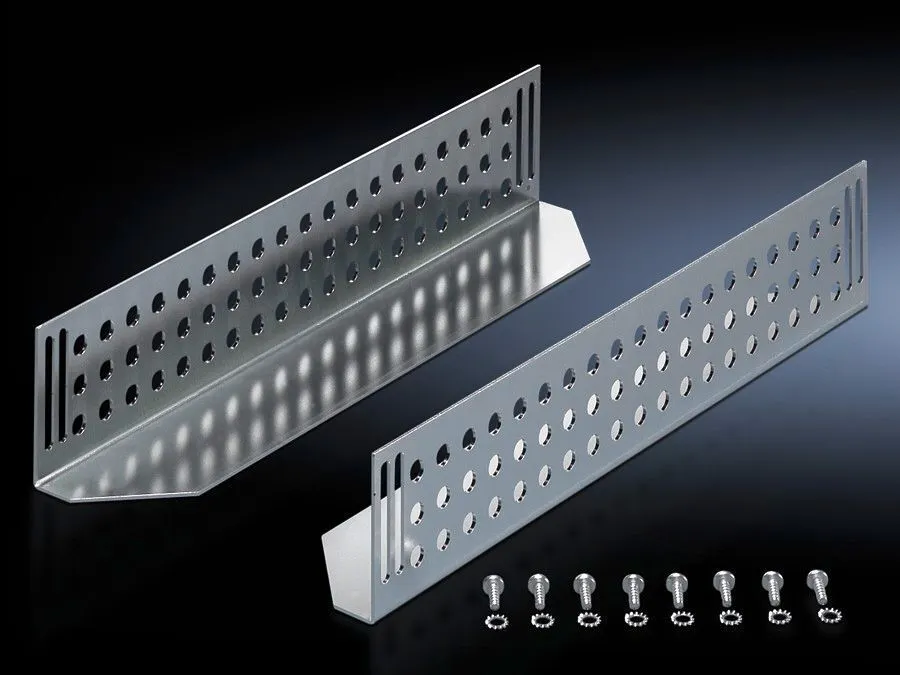

For mounting between the front and rear 482.6 mm (19") mounting levels. The slide rails can be used to support heavy 482.6 mm (19") components.

Material

Sheet steel

Surface finish

Zinc-plated

Supply includes

Assembly parts

Distance between mounting levels

395 mm

Load capacity static

800 N

Contact surface

Width: 85 mm | Depth: 324 mm

To fit

Enclosure type: TE 8000 | EL

Installation dimensions

Installation depth for components: 482.6 mm | Installation width for components: 19"

Packs of

2 pc(s).

Weight/pack

1.76 kg

Customs tariff number

73269098

EAN

4028177443938

ETIM 9

EC002620

ECLASS 8.0

27189261

Product description

DK Slide rail, support surface WxD: 85x324 mm, 80 kg, static, distance between levels:: 395 mm, For TE

Feature: Load capacity static of 800 N ensures robust support for heavy 482.6 mm (19”) components, preventing sag and premature wear on critical connections. This translates to higher duty cycle and fewer panel inspections after installation, particularly in vibration-prone environments such as manufacturing lines and packaging equipment. By selecting a rail consistent with TE 8000 and EL enclosure standards, your team gains predictable performance during commissioning and future upgrades. Feature: The 395 mm distance between mounting levels provides precise, repeatable spacing aligned with standard 19” equipment footprints. This improves airflow, cable management, and service accessibility, reducing hotspots and downtime during maintenance. In practice, engineers can plan layouts with confidence, knowing components will align with pre-punched DIN rails and existing hardware. Feature: The contact surface measures 85 mm by 324 mm, delivering a stable footprint that resists tilt and lateral movement under load. Benefits include reduced risk of component shift during transport or operations and easier alignment with adjacent rails. This compatibility is essential for modular data and power distribution sections within TE 8000 enclosures. Feature: Construction uses zinc-plated sheet steel, combining mechanical strength with corrosion resistance in industrial settings. The result is longer service life and lower maintenance costs, even in environments with humidity or splashes. For installers, this means fewer fastener replacements, less repainting, and quicker panel refurbishments. Feature: Supplied in packs of two rails with assembly parts, weighing 1.76 kg per pack, simplifies logistics and reduces on-site handling time. The two-rail configuration supports balanced loading and symmetric mounting, improving panel aesthetics and serviceability. Procurement teams benefit from clear packs-of-two documentation that aligns with TE 8000 and EL specifications. Feature: The DK 7963.310 is designed to fit TE 8000 and EL enclosures with 482.6 mm installation depth and 19” width, ensuring plug-and-play compatibility with existing 19” equipment. Installation flexibility minimizes field customization and accelerates project timelines, particularly when standard 19” racks are already in use. Overall, this slide rail delivers reliable mechanical support while preserving the modularity needed for future upgrades.

Get a Quick Quote for a Rittal 7963310

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 7963310?

Enquire Now

FAQs

DK 7963.310 is sized to fit TE 8000 and EL enclosures with a 482.6 mm, 19" mounting depth and 19" width. Before install, verify compatibility with your enclosure’s mounting angles and ensure the assembly parts are included in the package. Plan for a two-rail configuration to support symmetrical load distribution, preserve channel alignment, and simplify future maintenance and upgrades.

The rail provides a static load capacity of 800 N and a mounting level separation of 395 mm. These specs support secure retention of heavy 19" components while maintaining consistent airflow and service clearance. In vibration-prone environments, the defined spacing helps prevent component shift, aiding reliability during continuous operation and inspections.

Yes. The 800 N static load rating and the 19" mounting compatibility make it suitable for supporting heavy power distribution modules and related equipment within TE 8000 and EL enclosures. The 85x324 mm contact surface provides a stable footprint, reducing tilt and movement during both installation and operation, which is critical for power reliability and signal integrity.

The DK 7963.310 references ETIM 9 EC002620 and ECLASS 8.0 27189261, helping align cataloging and cross-system procurement. It also carries an EAN of 4028177443938 for traceability. While explicit CE or IP ratings are not listed in the data, verify certification with the supplier to ensure your project-specific compliance requirements are met.

The zinc-plated sheet steel construction offers corrosion resistance for longer service life, reducing frequency of replacements and repainting. Its 800 N load capacity and precise 395 mm spacing minimize rework during upgrades and maintenance, accelerating panel refurbishments and improving uptime. The two-pack configuration also simplifies logistics and on-site handling, contributing to lower total cost of ownership.