Rittal 7979256 PDU metered RCM - Differential current per fuse

Part Number: 7979256

Manufacturer

Rittal

Part number

7979256

Category

Alt Part Number

DK 7979.256

Quick Summary

The PDU metered RCM for IT racks provides per‑phase energy measurement and differential current monitoring per fuse. In data centers and busy server rooms, visibility into rack power usage is often incomplete, leading to inefficiencies and unplanned downtime. This unit is CE‑compliant and EN 62368‑1 certified, with EMC Directive 2014/30/EU adherence to ensure reliable operation in regulated environments. By delivering precise energy data and fuse‑level current measurements, it supports accurate capacity planning and fault detection. The integration of USB configuration, web access, and VX IT enclosure compatibility translates into faster deployments and a lower total cost of ownership for IT teams and integrators.

Product Information

Extended Description

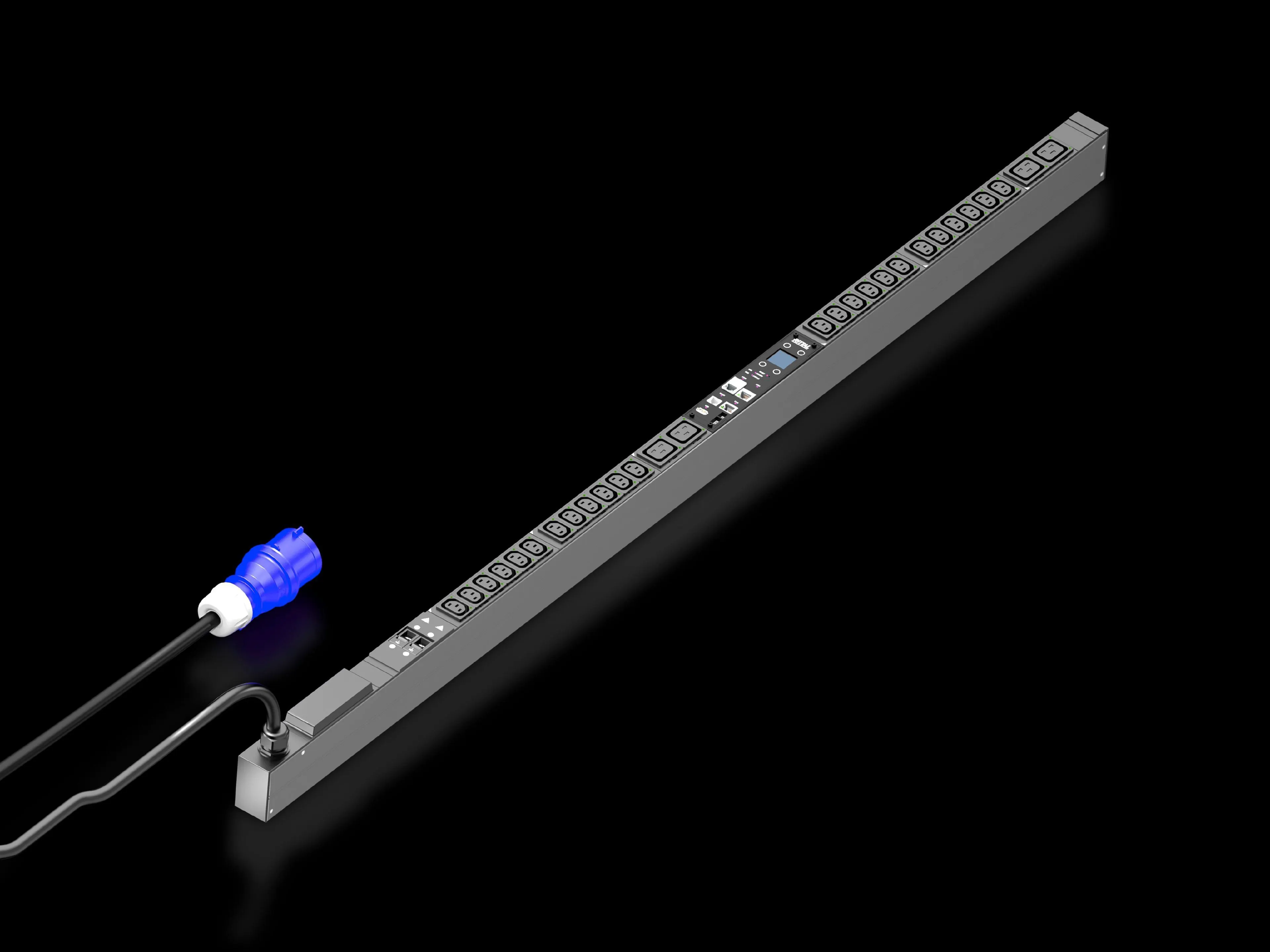

7979256 Rittal: DK PDU metered RCM, compact basic power distribution incl. energy measurement per phase, with network interface and display, WLD: 44x1695x70 mm, IEC 60 320: 24xC13 und 4xC19, differential current measurement (Type B – AC/DC) per fuse, measuring range 0 mA – 100 mA

Article number

DK 7979.256

Design

Incl. RCM

Product description

High-end power distribution in a compact design for IT network and server racks. With power measurement at the infeed or per phase.

Benefits

Metered PDU with integral differential current measurement (RCM / type B). The differential current is measured for each 16 A fuse.

Technical specifications

Display/controller unit in the PDU enclosure rotatable through 180° and replaceable

Material

Aluminium section, black anodised | Slots: Plastic

Supply includes

Assembly parts

Options

Type 3 overvoltage protection with interchangeable arresters while operational, with status monitoring, suitable for integration into PDU enclosure | Monitoring of the optionally available overvoltage protection | CMC III CAN bus sensors may be connected for ambient monitoring, max. 16 sensors | Other enclosure colours are available

Measurement functions, description

Differential current measurement (type B – AC/DC) per fuse, measuring range 0 mA– 100 mA

Dimensions

Width: 44 mm | Depth: 70 mm | Length: 1,695 mm

No. of sockets and type

24 x C13 / 4 x C19

Rated operating voltage

230 V AC

Rated current (max.)

32 A

Power consumption

7.4 kW

Infeeds

Qty.: 1 | Phases per infeed: 1~

Length of connection cable

3 m

Type of electrical connection

CEE

Interfaces

USB 2.0 port (USB-A) for mass configuration, firmware updates & data logging

Number RJ45 ports for sensor units max

2

Directives

EMC Directive 2014/30/EU

Standards

EN 62368-1

Protocols

Web server (HTTP, HTTPS, SSL) SSH, Telnet, NTP

Operating temperature range

5 °C...50 °C

Ambient humidity (non-condensing)

10...95 %

Storage temperature range

-20 °C...70 °C

To fit

Enclosure type: VX IT enclosure frame: ≥ 1,800 mm | Enclosure type: VX IT 19" mounting angles: ≥ 1,800 mm

Packs of

1 pc(s).

Weight/pack

5.7 kg

Customs tariff number

85366990

EAN

4028177967946

ETIM 9

EC002762

ETIM 8

EC002762

ECLASS 8.0

27142604

Product description

DK PDU metered RCM, compact basic power distribution incl. energy measurement per phase, with network interface and display, WLD: 44x1695x70 mm, IEC 60 320: 24xC13 und 4xC19, differential current measurement (Type B – AC/DC) per fuse, measuring range 0 mA – 100 mA

Feature → Business Impact → Application: Energy measurement per phase enables accurate monitoring of IT rack load, reducing over-provisioning and improving capacity planning for data centers and server rooms. Application: Use in IT racks to track real power consumption and identify rogue loads while complying with energy reporting requirements. Feature → Business Impact → Application: Differential current measurement per fuse (0 mA–100 mA, Type B – AC/DC) provides fault‑finding granularity, cutting mean time to repair and minimizing downtime in critical deployments. Application: Per‑fuse fault detection supports proactive maintenance for high-availability environments. Feature → Business Impact → Application: Rotatable 180° display and replaceable controller unit simplify maintenance, firmware updates, and field servicing, reducing maintenance cycles and technician time. Application: Field installations across multi-rack deployments with minimal downtime. Feature → Business Impact → Application: 24 x C13 / 4 x C19 outlets and 3 m connection cable enable flexible, scalable IT power distribution within VX IT enclosures, improving cable management and system integration. Application: Data center rack provisioning with standardized IT outlets. Feature → Business Impact → Application: USB 2.0 for mass configuration, firmware updates, and data logging accelerates provisioning, auditing, and compliance reporting. Application: Enterprise IT and MSP environments requiring rapid rollout and traceable configuration. Feature → Business Impact → Application: Compact dimensions (W 44 mm, D 70 mm, L 1,695 mm) and 32 A rating deliver high density within VX IT frames, enabling efficient space utilization. Application: Modern micro‑data centers and high‑density server rooms seeking space optimization.

Get a Quick Quote for a Rittal 7979256

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 7979256?

Enquire Now

FAQs

Yes. The DK 7979.256 PDU is designed to fit VX IT enclosure frames and 19" mounting angles with a recommended enclosure width alignment of at least 1,800 mm. It also supports the 44 mm width, 1,695 mm length form factor and comes with a 3 m connection cable for flexible installation in IT racks.

The PDU provides differential current measurement per fuse in the range of 0 mA to 100 mA (Type B – AC/DC), enabling precise monitoring and quick fault isolation at the fuse level to reduce downtime.

Configuration and data logging are supported via USB 2.0 (USB‑A) for mass configuration and firmware updates, plus a web server with HTTP/HTTPS/SSL, SSH, Telnet, and NTP for remote monitoring and time synchronization, simplifying deployment and ongoing management.

The product adheres to EMC Directive 2014/30/EU and EN 62368-1 safety standard, with CE compliance. These certifications help ensure safe operation in regulated environments and compatibility with modern IT equipment standards.

By providing per‑phase energy data and per‑fuse current measurements, the PDU supports accurate energy budgeting, early fault detection, and proactive maintenance. This leads to reduced downtime, better capacity planning, and lower energy costs, delivering measurable ROI in data center operations.