Rittal 8001213 Gland Plate VX Enclosures - UL Listed

Part Number: 8001213

Quick Summary

Rittal 8001213 gland plate is a modular component that enables custom floor-space configuration for VX enclosures. In busy control cabinets, misaligned bases and missing grounding paths slow assembly and increase safety risk. It carries UL Listed certification and aligns with ETIM EC002620 and ECLASS 27189261 standards, ensuring compliance for procurement and engineering reviews. By providing assembly parts and earthing points, the gland plate simplifies installation and improves electrical continuity. Zinc-plated sheet steel enhances corrosion resistance, and the included documentation aligns with VX family compatibility for streamlined projects.

Product Information

Extended Description

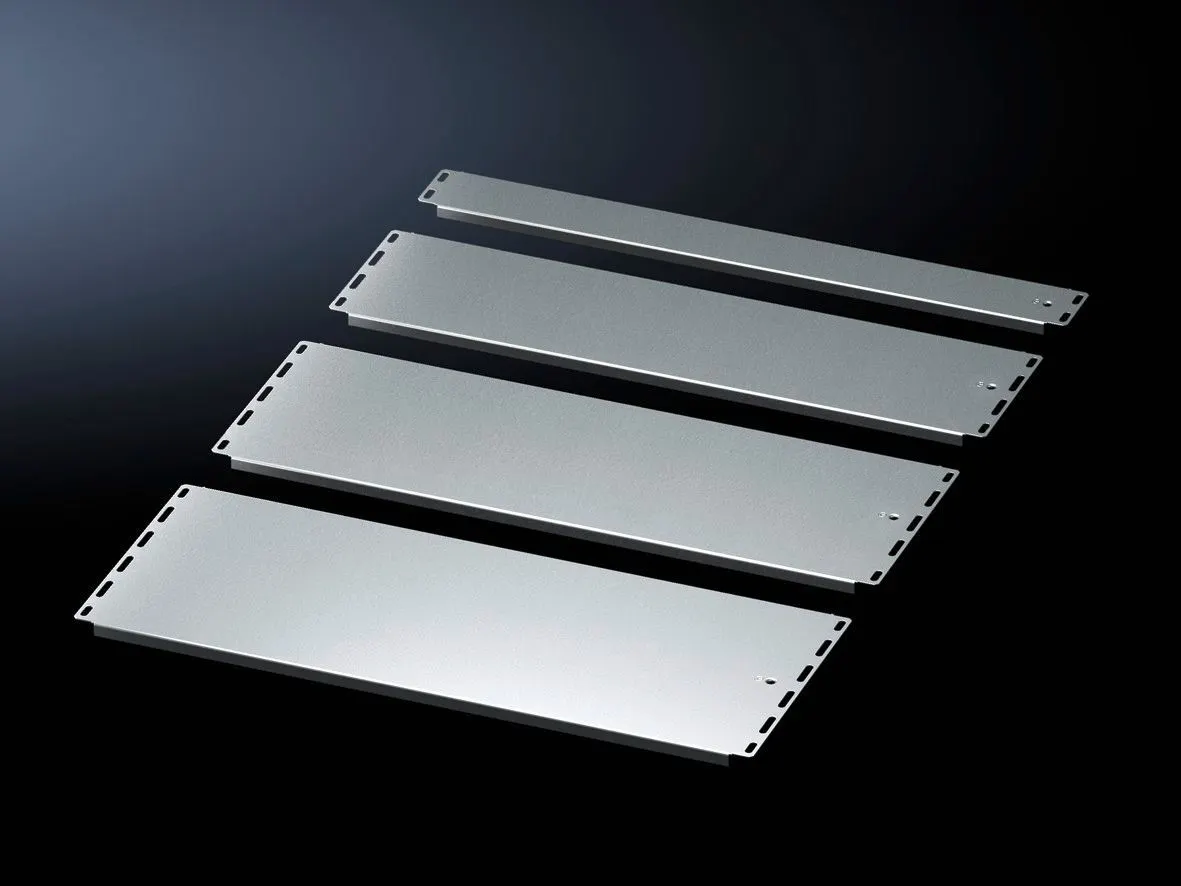

8001213 Rittal: VX Gland plate, WD: 1200x75 mm

Article number

VX 8001.213

Product description

For individual configuration of the floor space. Potential equalisation is achieved via assembly components and earthing points.

Material

Sheet steel

Surface finish

Zinc-plated

Supply includes

Assembly parts

Note

At least one sliding plate is required to fully seal a base opening.

Note on Model No.

For one enclosure half only

Dimensions

Width: 540 mm | Depth: 75 mm

To fit

Enclosure type: VX | VX IT | VX SE | CX one-piece console | CX pedestal | Width: = 1,200 mm

Packs of

1 pc(s).

Weight/pack

0.8 kg

Customs tariff number

73269098

EAN

4028177948686

ETIM 9

EC002620

ECLASS 8.0

27189261

Product description

VX Gland plate, WD: 1200x75 mm

The gland plate enables custom floor-space configuration on VX enclosures, delivering a defined mounting plane with dedicated earthing points that reduce installation rework and improve safety. This translates to faster commissioning and consistent electrical continuity across panels that require potential equalisation, particularly in VX, VX IT, and VX SE configurations. Made from sheet steel with a zinc-plated finish, it offers robust durability and corrosion resistance in harsh industrial environments, lowering long-term maintenance costs. With WD 1200x75 mm and a width of 540 mm, the plate fits VX width specifications up to 1,200 mm, enabling clean, scalable layouts for modular data, power, and control cabinets. Supplied parts simplify mounting, and the weight of 0.8 kg per pack keeps installation weight manageable without compromising rigidity. The included guidance notes help prevent missteps during base-sealing and enclosure-half configurations. This accessory aligns with ETIM EC002620 and ECLASS 27189261 standards, supporting accurate data exchange in ERP and procurement workflows.

Get a Quick Quote for a Rittal 8001213

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 8001213?

Enquire Now

FAQs

The VX 8001.213 gland plate is designed to fit VX, VX IT, VX SE, CX one-piece console, and CX pedestal configurations, with a base width up to 1,200 mm. To install, align the plate with the enclosure base openings, secure using the included assembly parts, and connect earthing points to establish reliable potential equalisation. Remember the note: at least one sliding plate is required to fully seal a base opening, and this gland plate is intended for one enclosure half.

Key specifications include width 540 mm and depth 75 mm, with a WD of 1200x75 mm. It is produced from sheet steel and finished with zinc plating to resist corrosion. Each pack contains one gland plate, with a weight of about 0.8 kg, and the supply includes necessary assembly parts for straightforward mounting in VX family enclosures.

Yes, the gland plate is UL Listed, reflecting safety compliance for electrical assemblies. It also aligns with ETIM 9 EC002620 and ECLASS 8.0 27189261 classifications, supporting standardized data exchange in purchasing and engineering workflows. These certifications help with regulatory alignment and procurement accuracy across industrial projects.

The VX 8001.213 includes assembly parts to facilitate mounting and grounding. However, per the product notes, at least one sliding plate is required to fully seal a base opening. This ensures proper enclosure sealing and mechanical compatibility. In practice, plan for the sliding plate(s) and ensure earthing connections are established using the gland plate’s built‑in earthing points.

Using the gland plate delivers measurable benefits: faster installation due to included assembly parts, improved grounding and potential equalisation, and enhanced corrosion resistance from zinc plating. Its compatibility with VX family enclosures reduces field modifications, supports safer maintenance, and lowers lifecycle costs by reducing commissioning time and rework in automated control cabinets.