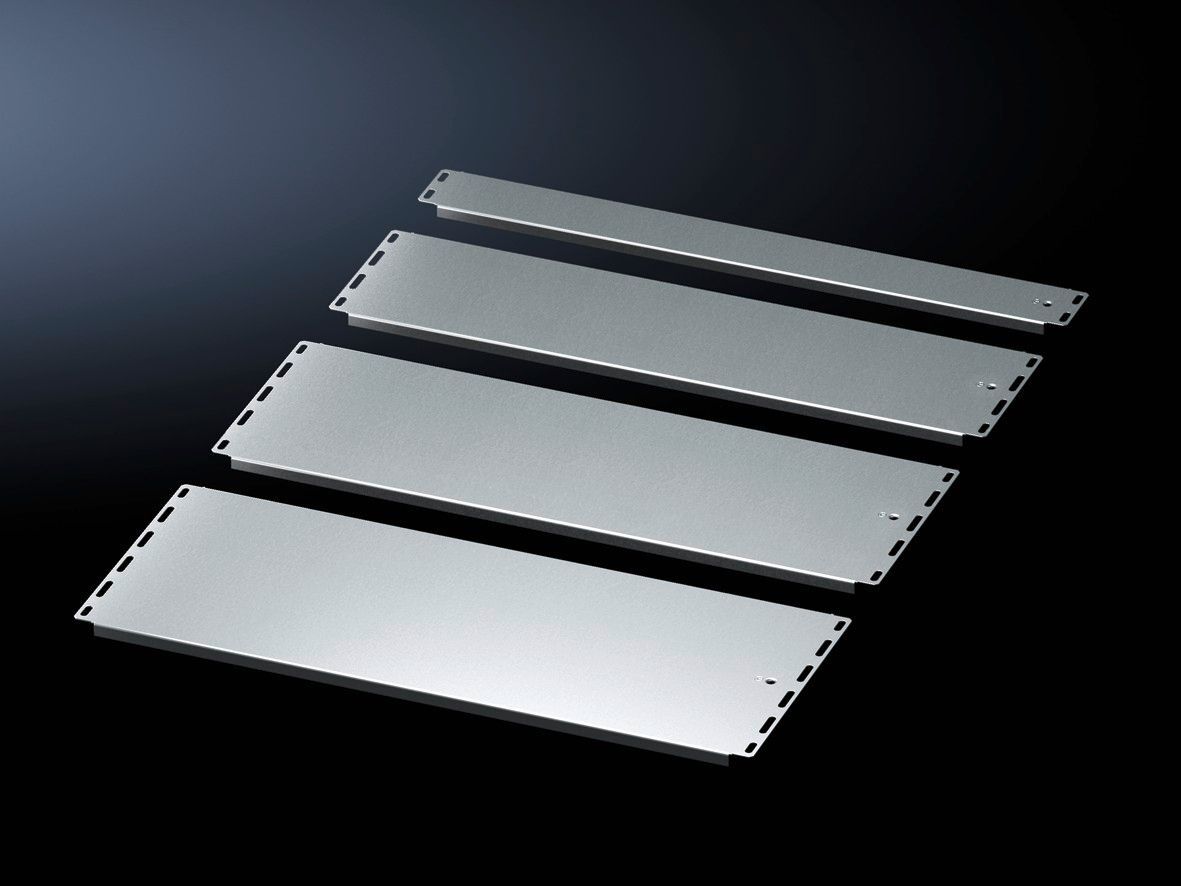

Rittal VX 8001.214 Gland Plate - Zinc-plated Sheet Steel

Part Number: 8001214

Quick Summary

Rittal VX 8001.214 gland plate configures VX enclosure floor-space for flexible installations. It helps engineers overcome rigid base openings by enabling modular layout and reliable grounding through assembly components and earthing points. Two critical certifications to verify are UL-listed status for electrical safety and CE conformity for EU markets; IP ratings depend on installation environment. Durability is enhanced by the zinc-plated sheet steel, supporting long service life in demanding environments. In practice, this accessory streamlines procurement and reduces field fabrication time, while maintaining compatibility with VX, VX IT, VX SE, CX consoles, and pedestals.

Product Information

Extended Description

8001214 Rittal: VX Gland plate, WD: 600x175 mm

Article number

VX 8001.214

Product description

For individual configuration of the floor space. Potential equalisation is achieved via assembly components and earthing points.

Material

Sheet steel

Surface finish

Zinc-plated

Supply includes

Assembly parts

Note

At least one sliding plate is required to fully seal a base opening.

Dimensions

Width: 490 mm | Depth: 175 mm

To fit

Enclosure type: VX | VX IT | VX SE | CX one-piece console | CX pedestal | Width: = 600 mm

Packs of

1 pc(s).

Weight/pack

1.26 kg

Customs tariff number

73269098

EAN

4028177948693

ETIM 9

EC002620

ECLASS 8.0

27189261

Product description

VX Gland plate, WD: 600x175 mm

Feature: Material and finish is sheet steel with a zinc-plated surface, delivering corrosion resistance and robust mechanical strength. Business impact: Lower maintenance costs and reduced downtime in harsh environments. Application: Ideal for industrial cabinets and outdoor-rated enclosures where longevity matters. Feature: Dimensions and fit - Width 490 mm, Depth 175 mm; To fit VX family enclosures with a 600 mm base width. Business impact: Ensures precise base footprint and predictable assembly, speeding install and reducing field modifications. Application: Works with VX, VX IT, VX SE, CX one-piece console, and CX pedestal configurations. Feature: Supply includes assembly parts; Business impact: Eliminates multiple supplier touchpoints and accelerates mounting readiness. Application: Quick integration into new builds or upgrades. Feature: Weight/pack 1.26 kg; Packs of 1 pc; Business impact: Manageable handling for on-site installation and inventory planning. Application: Simplifies logistics and stocking in procurement workflows. Feature: Note and compatibility - At least one sliding plate is required to fully seal a base opening; To fit details specify VX family and 600 mm width. Business impact: Ensures proper sealing, grounding, and EMI control. Application: Reduces rework and warranty issues when configuring bases.

Get a Quick Quote for a Rittal 8001214

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 8001214?

Enquire Now

FAQs

The gland plate is designed to fit VX family enclosures and is specified to be compatible with VX, VX IT, VX SE, plus CX one-piece consoles and CX pedestals. It targets a base width of 600 mm, with a gland plate footprint of 490 mm in width and 175 mm in depth, enabling consistent integration across these enclosure lines.

Material is sheet steel with a zinc-plated surface finish for corrosion resistance. Dimensions are Width 490 mm and Depth 175 mm. It is supplied as 1 piece per pack, with a weight of approximately 1.26 kg. The EAN is 4028177948693, and the customs tariff Number is 73269098.

The product listing references UL-listed assets, indicating electrical safety compliance in UL contexts. CE conformity is not explicitly stated in the provided data; verify CE compliance with your supplier for EU-market usage and any regional requirements relevant to your project.

The VX 8001.214 includes assembly components and earthing points to facilitate potential equalisation and grounding connections. This supports safe operation and reduces wiring complexity when configuring the base area of VX enclosures, while the note indicates that at least one sliding plate is required to fully seal the base opening.

Plan the base layout using the 600 mm width guideline, ensure you have the included assembly parts ready, connect grounding points as you assemble, and install a sliding plate to seal the base opening. This approach minimizes field fabrication, improves grounding reliability, and speeds up commissioning in VX-based installations.