Rittal 8001216 VX Gland plate - Zinc-plated

Part Number: 8001216

Quick Summary

Rittal 8001216 VX Gland plate enables flexible floor-space configuration for VX enclosures. This accessory supports precise layout customization while maintaining routing paths and earth connections in compact cabinets. It addresses the common challenge of sealing base openings when configuring modular frames, reducing dust ingress and improving enclosure integrity. The product aligns with UL-listed safety documentation and industry classifications such as ETIM EC002620 and ECLASS 8.0 27189261, helping procurement teams verify specs quickly. By simplifying assembly with included components and a standard footprint, it accelerates installation and lowers total cost of ownership. This gland plate pairs with VX, VX IT, VX SE and CX pedestal systems to deliver scalable, reliable data-center or industrial control applications.

Product Information

Extended Description

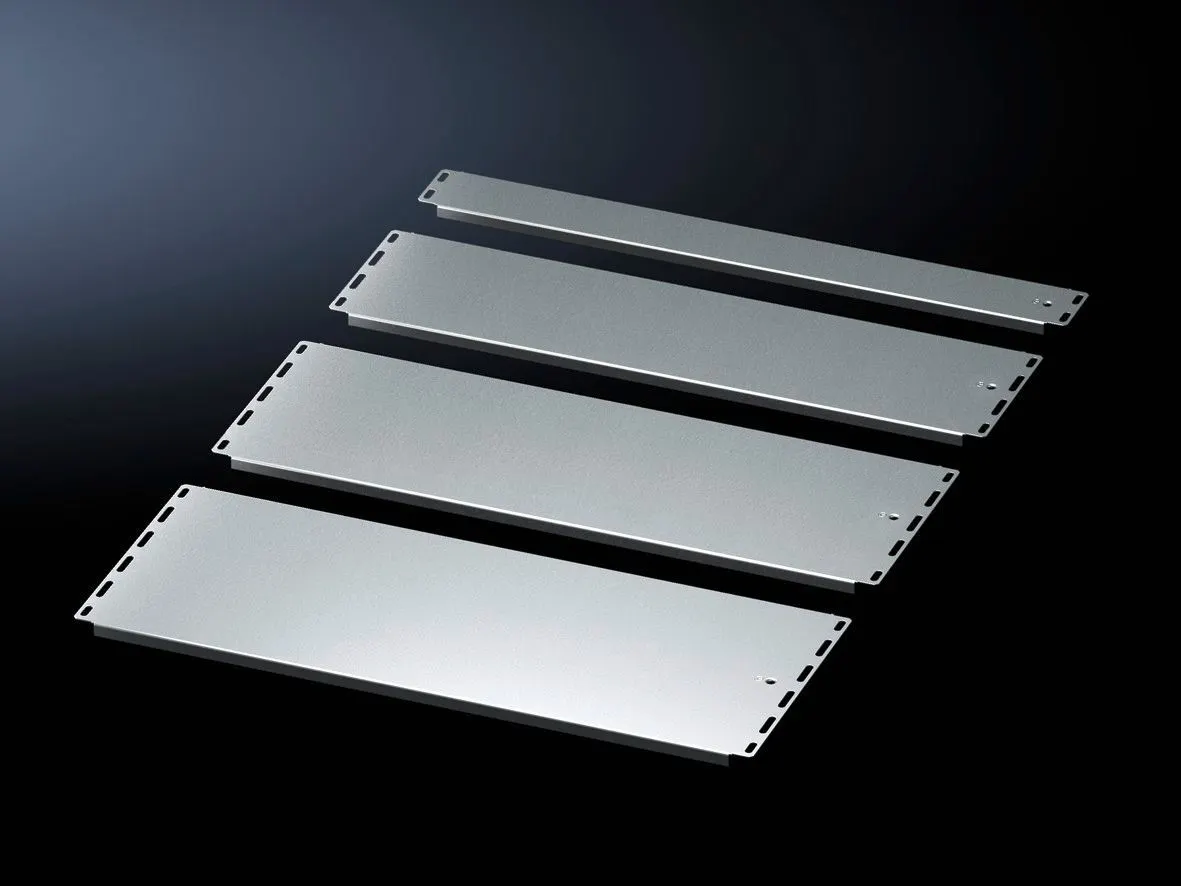

8001216 Rittal: VX Gland plate, WD: 1000x175 mm

Article number

VX 8001.216

Product description

For individual configuration of the floor space. Potential equalisation is achieved via assembly components and earthing points.

Material

Sheet steel

Surface finish

Zinc-plated

Supply includes

Assembly parts

Note

At least one sliding plate is required to fully seal a base opening.

Dimensions

Width: 440 mm | Depth: 175 mm

To fit

Enclosure type: VX | VX IT | VX SE | CX one-piece console | CX pedestal | Width: = 1,000 mm

Packs of

1 pc(s).

Weight/pack

1.12 kg

Customs tariff number

73269098

EAN

4028177948716

ETIM 9

EC002620

ECLASS 8.0

27189261

Product description

VX Gland plate, WD: 1000x175 mm

Feature: 440 mm width and 175 mm depth gland plate, fabricated from sheet steel with a zinc-plated finish. Business impact: delivers a robust, corrosion-resistant base closure that supports reliable floor-space configuration while maintaining electrical continuity. Application: ideal for VX series enclosures and CX pedestals, enabling quick on-site adaptation and cleaner cable management. Feature: Potential equalisation is provided via assembly components and earthing points. Business impact: enhances electrical safety and reduces the risk of ground loops, contributing to safer, compliant installations. Application: suitable for control panels and automation cabinets where grounding integrity is critical. Feature: Includes assembly parts and a weight of 1.12 kg per pack. Business impact: simplifies procurement and speeds up installation, lowering labor costs and potential mismatch with external hardware. Application: supports fast, one-box configuration for VX VX IT VX SE and related enclosure types. Feature: Note that at least one sliding plate is required to fully seal a base opening. Business impact: prevents ingress of dust/moisture and preserves enclosure IP performance when used with the correct sealing sequence. Application: prevents performance degradation in dirty or dusty industrial environments. Feature: To fit VX, VX IT, VX SE, CX one-piece console, CX pedestal with width 1000 mm. Business impact: broad compatibility reduces part numbers and simplifies maintenance forecasting. Application: scalable for modular factories and evolving automation layouts.

Get a Quick Quote for a Rittal 8001216

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 8001216?

Enquire Now

FAQs

Yes. The VX 8001.216 gland plate is designed to fit VX family enclosures, including VX IT and VX SE variants, as well as CX pedestals. It ships with assembly parts for straightforward mounting and aligns with the enclosure footprint for quick, error-free installation. Ensure the base opening is prepared with a compatible sliding plate for full sealing.

Key specs: Width 440 mm, Depth 175 mm, WD 1000x175 mm, material sheet steel, surface zinc-plated. Pack contains 1 piece with a weight of 1.12 kg per pack. The gland plate is designed to provide a configurable floor space while maintaining grounding paths via earthing points.

The gland plate includes earthing points and assembly components that enable reliable potential equalisation across the enclosure base. This reduces risk of ground loops and supports proper electrical safety standards during configuration and maintenance of VX-based control cabinets.

The product references UL-listed documentation and industry classification data (ETIM 9 EC002620 and ECLASS 8.0 27189261), which aid in compliance verification and data-model consistency when selecting enclosure accessories for industrial automation deployments.

By enabling rapid, modular floor-space configuration and reducing base-sealing errors, the gland plate cuts installation time, lowers labor costs, and minimizes rework. Its included assembly parts and compatibility with multiple VX variants further streamline procurement and maintenance planning for ongoing automation projects.