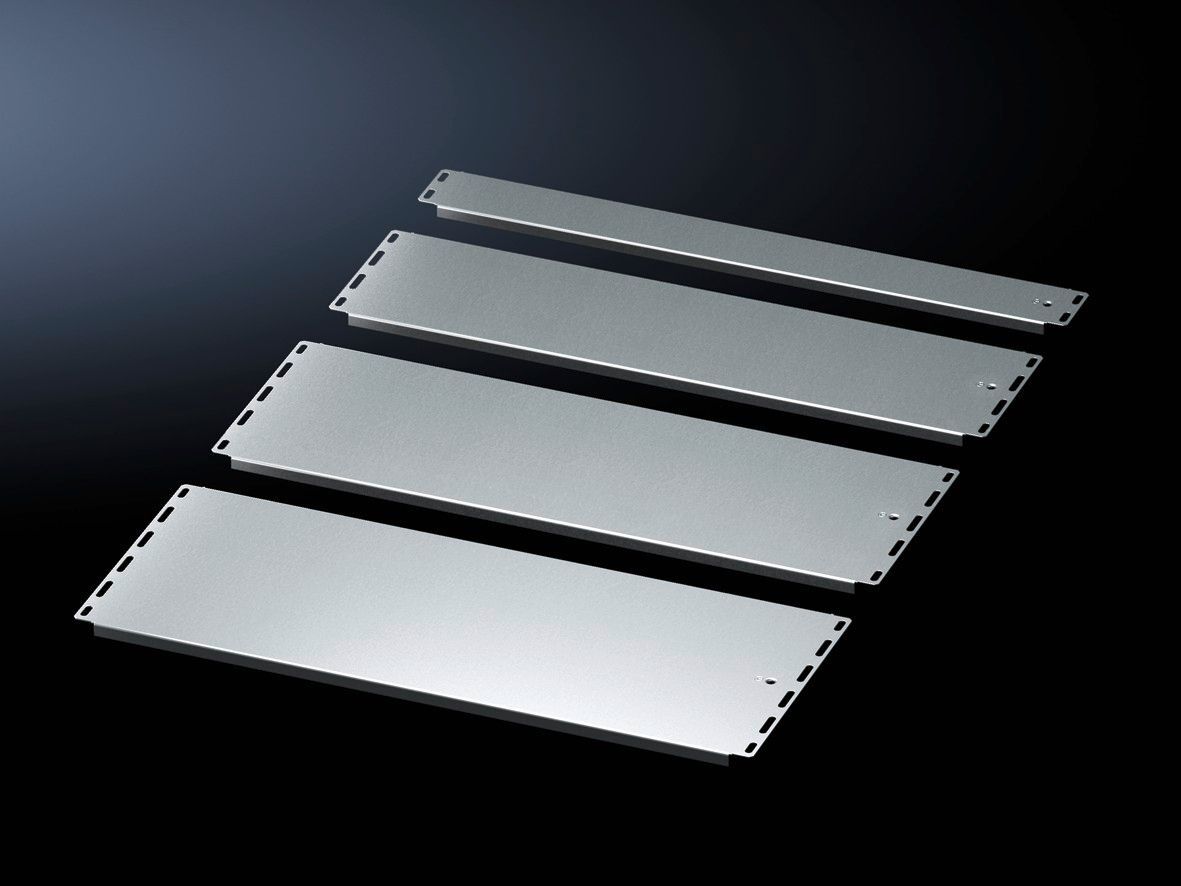

Rittal VX 8001.219 Gland Plate - Zinc-plated

Part Number: 8001219

Quick Summary

Rittal VX 8001.219 Gland Plate enables precise floor-space configuration for VX enclosure systems. Designed for VX, VX IT, VX SE and CX configurations, it aligns with typical distributor workflows. Engineers often wrestle with sealing base openings and achieving reliable potential equalisation in confined layouts. UL-listed documentation and standard industry practices support safe, compliant installations, with common CE and IP considerations in VX deployments. The gland plate offers rapid, tool-free assembly with predictable weight and scalable compatibility, reducing field rework and total cost of ownership. For teams aiming to keep cabinets clean, safe, and reliable, this component delivers measurable business value through improved safety margins and installation efficiency.

Product Information

Extended Description

8001219 Rittal: VX Gland plate, WD: 800x237,5 mm

Article number

VX 8001.219

Product description

For individual configuration of the floor space. Potential equalisation is achieved via assembly components and earthing points.

Material

Sheet steel

Surface finish

Zinc-plated

Supply includes

Assembly parts

Note

At least one sliding plate is required to fully seal a base opening.

Dimensions

Width: 690 mm | Depth: 237.5 mm

To fit

Enclosure type: VX | VX IT | VX SE | CX one-piece console | CX pedestal | Width: = 800 mm

Packs of

1 pc(s).

Weight/pack

2.3 kg

Customs tariff number

73269098

EAN

4028177948747

ETIM 7.0

EC002620

ECLASS 8.0

27189261

Product description

VX Gland plate, WD: 800x237,5 mm

Feature: Material and finish – sheet steel with zinc-plated surface provides corrosion resistance and a durable finish, while assembly parts are included to speed initial setup. Business impact: Longer service life in harsh environments reduces replacement cycles and warranty costs. Application: Ideal for VX enclosure lines in manufacturing plants and data centers seeking robust cable management and stable grounding. Feature: Individual floor-space configuration – supports customization of enclosure footprints and ensures consistent potential equalisation via built-in earthing points. Business impact: Improves electrical safety, reduces stray currents, and lowers field adjustment time. Application: Suitable for tight installations where base openings must be sealed without compromising accessibility to internal components. Feature: Dimensional fit and compatibility – width 690 mm, depth 237.5 mm, to fit VX, VX IT, VX SE and CX configurations; packs of 1 with a weight of 2.3 kg per pack. Business impact: Streamlines planning, reduces packing variance, and simplifies procurement for large projects. Application: Perfect for multi-enclosure racks and modular deployments in industrial automation. Feature: Installation guidance – requires at least one sliding plate to fully seal a base opening, ensuring sealing integrity and IP considerations are met. Business impact: Minimizes rework and protects against moisture ingress in rugged environments. Application: Useful guidance for field technicians during assembly of VX-based systems. Feature: Standards alignment – ETIM 7.0 EC002620 and ECLASS 8.0 27189261, with UL-listed documentation available for buyers. Business impact: Improves data quality in ERP systems and accelerates compliance audits. Application: Valuable for procurement teams and compliance reviews in global manufacturing operations.

Get a Quick Quote for a Rittal 8001219

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 8001219?

Enquire Now

FAQs

The gland plate is designed to fit VX, VX IT, VX SE and CX configurations with a width of 800 mm and depth of 237.5 mm. It ships in packs of 1 and includes assembly components for quick integration. Verify enclosure width and base opening dimensions before installation for a proper seal.

Ensure potential equalisation is achieved via the included assembly components and earthing points. Note that at least one sliding plate is required to fully seal a base opening, which helps maintain enclosure integrity and reduces ingress risks in demanding environments.

The gland plate aligns with ETIM 7.0 EC002620 and ECLASS 8.0 27189261 classifications, and UL-listed documentation is available to support compliance audits and supplier data accuracy in ERP systems.

The design supports rapid, tool-free assembly and scalable compatibility, which reduces field rework and commissioning time. Long-term maintenance benefits include improved grounding reliability and a durable zinc-plated finish that resists corrosion in harsh environments.

By enabling precise floor-space configuration, simplifying procurement with a 1 pc pack, and reducing rework through reliable sealing and footing grounding, the gland plate lowers installation labor and replacement costs over the system lifetime.