Rittal 8001220 VX Gland Plate - Zinc-plated Sheet Steel

Part Number: 8001220

Quick Summary

Rittal 8001220 VX Gland Plate enables custom floor-space configuration for VX enclosures, improving mounting integrity and earth continuity. Engineers often wrestle with uneven base openings and incomplete potential equalisation, which can cause misalignment and costly rework in panel builds. This accessory aligns with UL-listed documentation and industry data standards, including ETIM 9 EC002620 and ECLASS 8.0 27189261, supporting reliable procurement and cross-system compatibility. By delivering a ready-to-install gland plate with assembly parts, it reduces on-site installation time, enhances earthing reliability, and contributes to lower lifecycle costs while maintaining stringent industrial standards for VX and CX configurations.

Product Information

Extended Description

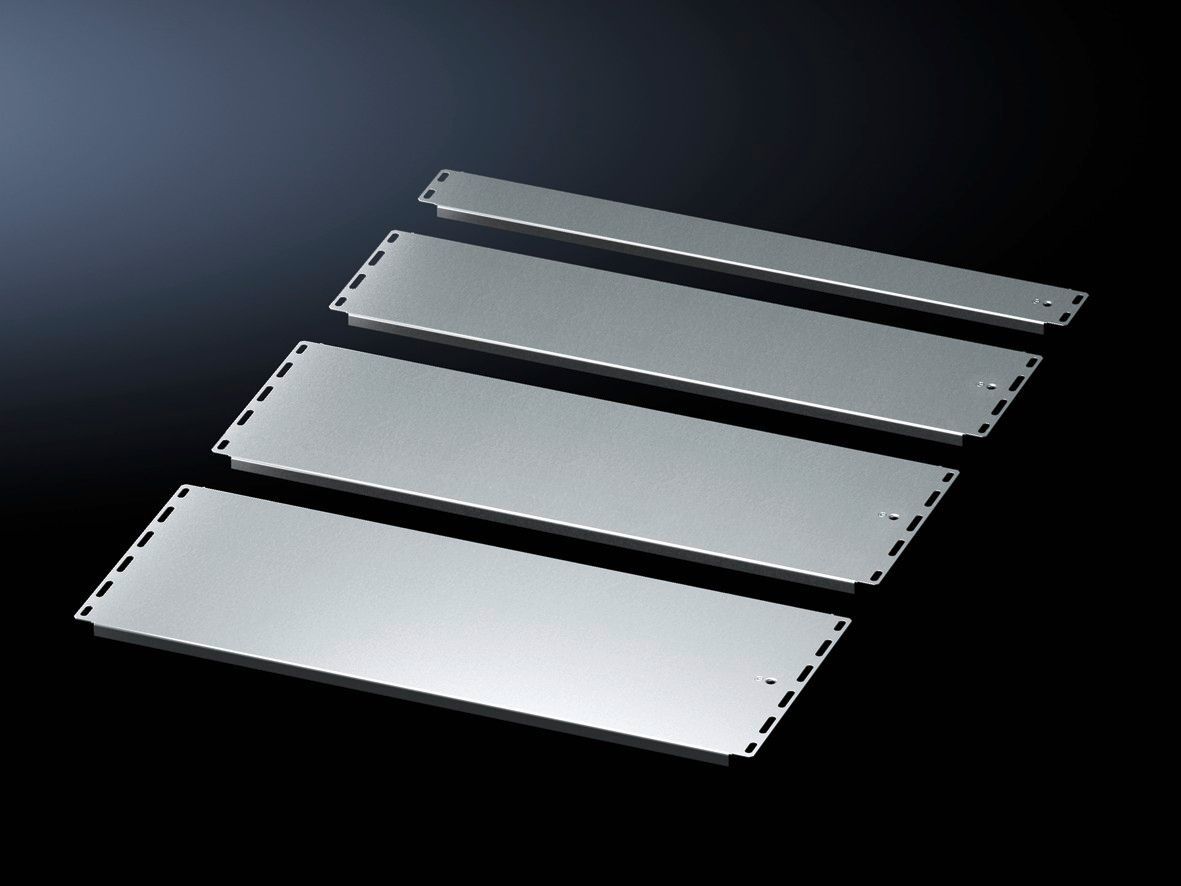

8001220 Rittal: VX Gland plate, WD: 1000x237,5 mm

Article number

VX 8001.220

Product description

For individual configuration of the floor space. Potential equalisation is achieved via assembly components and earthing points.

Material

Sheet steel

Surface finish

Zinc-plated

Supply includes

Assembly parts

Note

At least one sliding plate is required to fully seal a base opening.

Dimensions

Width: 440 mm | Depth: 237.5 mm

To fit

Enclosure type: VX | VX IT | VX SE | CX one-piece console | CX pedestal | Width: = 1,000 mm

Packs of

1 pc(s).

Weight/pack

1.48 kg

Customs tariff number

73269098

EAN

4028177948754

ETIM 9

EC002620

ECLASS 8.0

27189261

Product description

VX Gland plate, WD: 1000x237,5 mm

Feature → Business Impact → Application: The VX 8001.220 gland plate uses sheet steel and a zinc-plated finish to resist corrosion and withstand demanding industrial environments, delivering a durable base for enclosure configurations; this increases maintenance intervals and reduces replacement costs in plant environments. Application-wise, it supports precise floor-space configuration for VX, VX IT, VX SE, CX one-piece consoles, and CX pedestals, enabling consistent mounting and faster project handoffs. Feature → Business Impact → Application: Dimensions WD 1000 x 237.5 mm with a width of 440 mm and depth of 237.5 mm ensure predictable fit within standard VX footprints, simplifying procurement and install planning; engineers gain repeatable mounting surfaces and reduced field adaptation. Feature → Business Impact → Application: Weight per pack of 1.48 kg and packed as 1 pc promote straightforward logistics and lower freight costs, improving job-site efficiency during enclosure upgrades. Feature → Business Impact → Application: Supply includes assembly parts and a note that at least one sliding plate is required to seal a base opening, speeding installs and ensuring regulatory-compliant base sealing; this reduces commissioning risk and post-installation rework. Feature → Business Impact → Application: Data alignment with ETIM 9 EC002620 and ECLASS 8.0 27189261 enables seamless ERP integration and accurate part classification, reducing procurement errors and improving stock accuracy.

Get a Quick Quote for a Rittal 8001220

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 8001220?

Enquire Now

FAQs

Yes. The gland plate is designed for VX family enclosures and CX consoles/pedestals, with a 1000 mm width fit to align with VX base footprints. It ships as a single pack containing assembly parts and requires at least one sliding plate to seal the base opening for proper enclosure integrity.

The unit is made from sheet steel with a zinc-plated surface for corrosion resistance. Dimensions are Width 440 mm and Depth 237.5 mm, with a WD of 1000 x 237.5 mm. Each pack contains 1 piece and weighs 1.48 kg, enabling straightforward handling and installation.

The VX 8001.220 provides designated earthing points and assembly components to achieve reliable potential equalisation, reducing electrical noise and improving safety in complex panel installations. Proper use requires installing at least one sliding plate to seal unused base openings.

Data alignment follows ETIM 9 EC002620 and ECLASS 8.0 27189261, supporting precise data models for procurement. The availability of UL-listed documentation (UL/C-UL) is indicated by related UL-listed data sheets, helping with cross-border compliance and supplier qualification.

By including assembly parts and providing a ready-to-install mounting surface, the gland plate reduces field labor time, minimizes rework due to misalignment, and shortens commissioning cycles. Its robust zinc-plated construction adds long-term corrosion protection, lowering maintenance costs over the enclosure’s lifecycle.