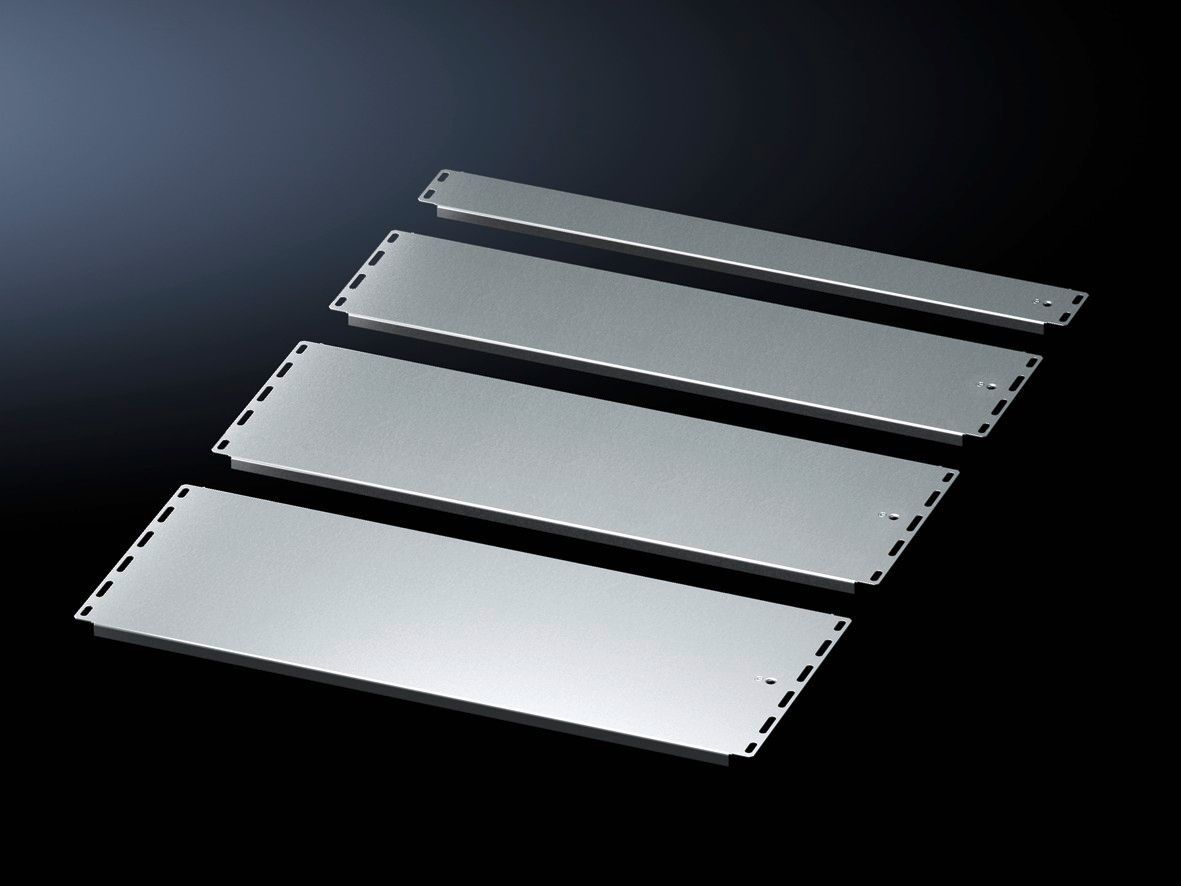

Rittal VX 8001.224 Gland plate - Zinc-plated

Part Number: 8001224

Quick Summary

Rittal VX 8001.224 gland plate enables precise floor-space configuration for VX family enclosures. Without adjustable floor space, wiring layouts and grounding points can drift, wasting panel real estate and complicating maintenance. This solution aligns with UL-listed configurations and critical classifications such as ETIM EC002620 and ECLASS 27189261 to streamline procurement. Its zinc-plated sheet steel construction and inclusion of assembly parts offer ready-to-install value for VX, VX IT, VX SE and CX enclosures. The gland plate also supports potential equalisation via earthing points, reducing setup time and improving reliability in industrial control cabinets. This combination delivers measurable benefits in installation speed, traceability, and long-term panel integrity.

Product Information

Extended Description

8001224 Rittal: VX Gland plate, WD: 1000x275 mm

Article number

VX 8001.224

Product description

For individual configuration of the floor space. Potential equalisation is achieved via assembly components and earthing points.

Material

Sheet steel

Surface finish

Zinc-plated

Supply includes

Assembly parts

Note

At least one sliding plate is required to fully seal a base opening.

Dimensions

Width: 440 mm | Depth: 275 mm

To fit

Enclosure type: VX | VX IT | VX SE | CX one-piece console | CX pedestal | Width: = 1,000 mm

Packs of

1 pc(s).

Weight/pack

1.7 kg

Customs tariff number

73269098

EAN

4028177948792

ETIM 9

EC002620

ECLASS 8.0

27189261

Product description

VX Gland plate, WD: 1000x275 mm

Feature: VX gland plate provides configurable floor-space within VX enclosures. Business Impact: Improves cable routing efficiency and shortens install time by giving installers repeatable mounting references. Application: Used in VX, VX IT, VX SE and CX consoles, including CX pedestal configurations, to tailor space for components. Feature: Potential equalisation via assembly components and earthing points. Impact: Ensures reliable earth continuity and safer operation during upgrades or routine maintenance. Application: Critical for power distribution and control panels in harsh industrial environments. Feature: Sheet steel construction with zinc-plated finish. Impact: Enhanced corrosion resistance and durability for long service life in factory floors and damp zones. Application: Suitable for aggressive environments across vehicle, automation, and IT cabinet applications. Feature: Dimensions and packaging details. Impact: WD 1000x275 mm with width 440 mm and depth 275 mm delivers predictable fit; weight per pack 1.7 kg; supply includes assembly parts, accelerating on-site installation. Application: Quick retrofits and OEM integrations across VX family products. Feature: Important installation note. Impact: At least one sliding plate is required to fully seal a base opening, ensuring enclosure integrity. Application: Critical in base-sealing steps during commissioning.

Get a Quick Quote for a Rittal 8001224

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 8001224?

Enquire Now

FAQs

Power down the enclosure, align the gland plate to the mounting points, and secure using the provided assembly parts. Ensure proper earthing connections through the integrated points and verify base-seal integrity with a sliding plate as required.

The gland plate is designed to fit VX, VX IT, VX SE enclosures as well as CX one-piece consoles and CX pedestals, with a overall footprint of WD 1000x275 mm and matching mounting interfaces.

Material is sheet steel with zinc-plated finish; supply includes assembly parts; dimensions WD 1000x275 mm, Width 440 mm, Depth 275 mm; weight per pack 1.7 kg; EAN 4028177948792; ETIM 9 EC002620; ECLASS 8.0 27189261.

Yes. The gland plate provides potential equalisation via assembly components and dedicated earthing points, enabling safer grounding and reliable electrical performance in control panels.

Installation is faster thanks to included assembly parts and a defined fit, reducing commissioning time. Corrosion resistance from zinc plating improves long-term durability, lowering maintenance costs and downtime in industrial environments.