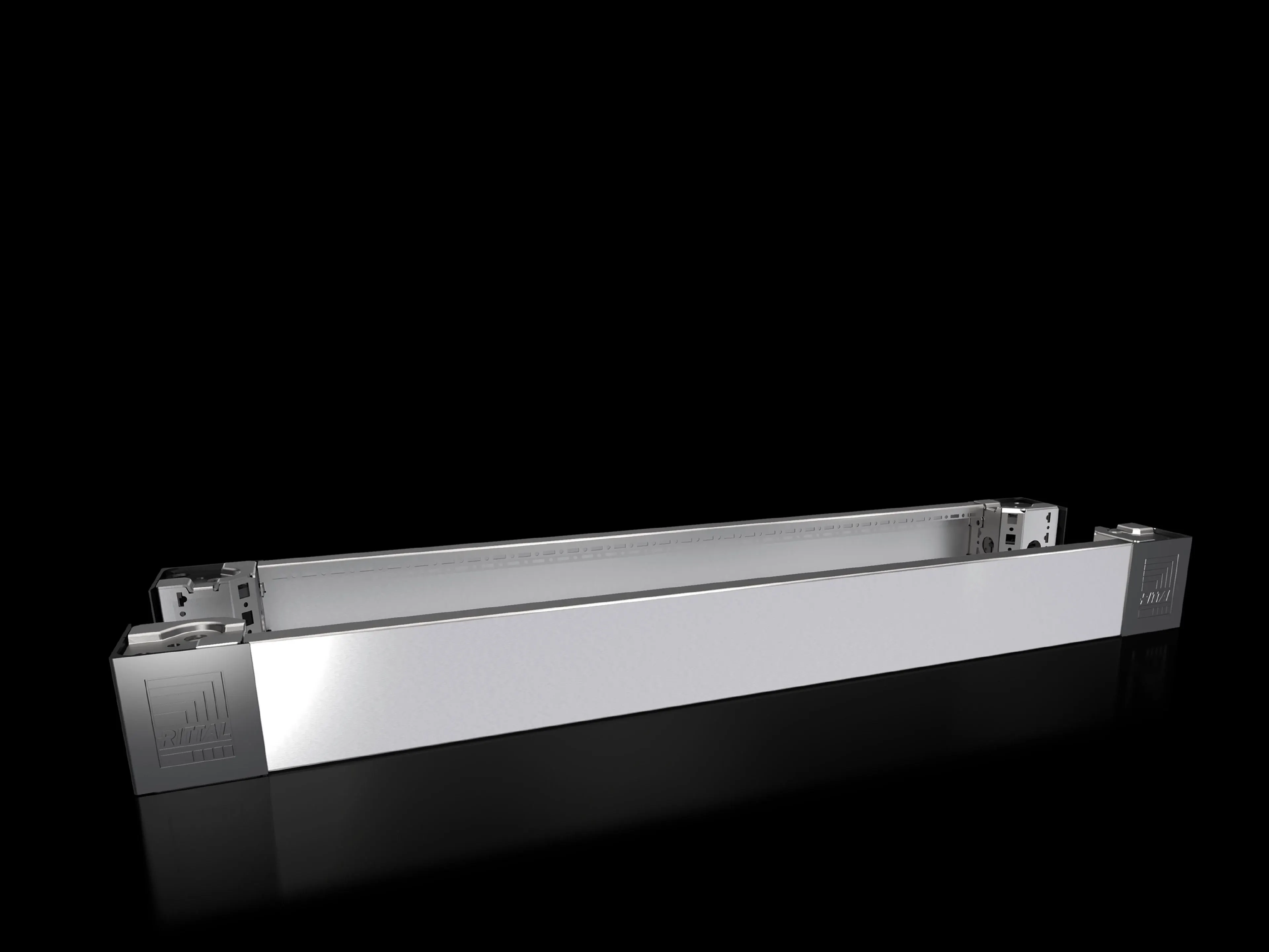

Rittal VX 8620.052 Base/plinth corner piece - Type 1

Part Number: 8620052

Quick Summary

Rittal VX 8620.052 Base/plinth corner piece enhances enclosure stability for bayed field enclosures. Engineers often face challenges aligning multiple units and fitting trim panels consistently; this component provides moulded self-positioning to simplify setup and reduce rework. The assembly leverages 1.4301 stainless steel and UL 50E Type 1 compatibility, aligning with ETIM EC000721 and ECLASS 27182003 standards to support procurement and compliance. By combining robust material with front/rear trim panels and corner covers, it enables flexible interior configuration and scalable expansion. The result is faster installation, improved rigidity, and a lower total cost of ownership for durable control cabinet networks.

Product Information

Extended Description

8620052 Rittal: VX Base/plinth corner piece, with base/plinth trim panel, front and rear, H: 100 mm, for W: 1000 mm, stainless steel, 1.4301

Article number

VX 8620.052

Product description

Base/plinth corner pieces with moulded self-positioning to the bayed enclosure system, for use with or without trim panels depending on the application. Large openings in the base/plinth corner piece for optimum access to the screw-fastening point may be concealed with a corner and baying cover.

Material

Base/plinth corner piece: Stainless steel 1.4301 (AISI 304) | Base/plinth trim panel front/rear: Stainless steel 1.4301 (AISI 304) | Corner and baying cover: Plastic

Surface finish

Trim panel: Brushed, grain size 400

Supply includes

4 base/plinth corner pieces | 4 corner covers | 1 baying cover | 2 base/plinth trim panels, front/rear, 100 mm high | Assembly parts

Note

Side base/plinth trim panels finish off a base/plinth unit or provide additional stabilisation between base/plinths or enable interior configuration of the base/plinth

Dimensions

Height: 100 mm

To fit

Width: = 1,000 mm

Type rating to UL 50E

Type 1

Weight/pack

7.99 kg

Packs of

2 pc(s).

Customs tariff number

94039910

EAN

4028177922310

ETIM 9

EC000721

ECLASS 8.0

27182003

Product description

VX Base/plinth corner piece, with base/plinth trim panel, front and rear, H: 100 mm, for W: 1000 mm, stainless steel, 1.4301

Feature: Moulded self-positioning to the bayed enclosure system. Business Impact: Speeds up installation and minimizes misalignment, reducing commissioning time and field errors. Application: Ideal for modular 1000 mm-wide bays where quick, repeatable corner alignment is required, such as multi-enclosure control rooms and automated lines. Feature: Stainless steel 1.4301 materials for corner pieces and trim panels. Business Impact: Delivers corrosion resistance and long-term durability in harsh environments, lowering maintenance intervals. Application: Suitable for industrial control cabinets exposed to humidity, dust, or cleaning regimes. Feature: Includes 4 base/plinth corner pieces, 4 corner covers, 1 baying cover, and 2 base/plinth trim panels. Business Impact: Streamlines procurement and reduces project lead times by providing complete installation kits. Application: Simplifies site scoping for new builds or retrofits of bayed enclosure systems. Feature: Height 100 mm and width to fit 1000 mm bays with UL 50E Type 1 rating. Business Impact: Ensures standard enclosure compatibility and safe mounting with recognized electrical safety criteria. Application: Fits standard 1,000 mm-wide enclosures used in industrial automation. Feature: Brushed surface finish on trim panels. Business Impact: Improves aesthetics and provides a durable, low-maintenance surface that resists wear in daily operation. Application: Front/rear panels in factory cabinets where appearance and longevity matter. Feature: Included assembly parts and corner covers facilitate quick installation. Business Impact: Reduces on-site labor and tool requirements, accelerating project timelines. Application: Installation crews can complete baying tasks with fewer sourcing delays. Feature: Pack configuration of 2 packs, weight ~7.99 kg per pack. Business Impact: Enables manageable handling and reduces lifting risk on site. Application: transport and staging in limited-access environments. Feature: Customs tariff 94039910, EAN 4028177922310, ETIM EC000721, ECLASS 27182003 identifiers. Business Impact: Improves traceability and supports cross-system data in ERP and procurement workflows. Application: Streamlined cataloging and part-level procurement across global sites.

Get a Quick Quote for a Rittal 8620052

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 8620052?

Enquire Now

FAQs

Prepare the base, align the four corner pieces with the bayed enclosure corners, and insert the supplied fasteners through the base/plinth corner pieces into the frame. Attach the front and rear trim panels, then snap in the corner covers and baying cover. The included assembly parts are designed to simplify alignment and reduce tool requirements during setup.

The base/plinth corner pieces and front/rear trim panels use stainless steel 1.4301 (AISI 304) with a brushed finish on the trim panels. This combination provides strong corrosion resistance and durability in typical industrial environments, helping to extend service life and reduce maintenance in damp or dusty cabinet applications.

VX 8620.052 is designed for bayed enclosure systems and includes 4 corner pieces, 4 corner covers, 1 baying cover, and 2 base/plinth trim panels. While it is optimized for Rittal bay configurations, it is important to verify dimension and mounting compatibility with any non-Rittal components prior to integration to ensure a secure fit.

The VX 8620.052 carries a UL 50E Type 1 rating for enclosure performance. It also references ETIM EC000721 and ECLASS 27182003 in its specification framework, aiding procurement and data exchange. These standards support reliable performance, component interoperability, and streamlined sourcing within regulated industrial environments.

The integration of moulded self-positioning corners, durable stainless steel components, and a complete installation kit reduces field labor, alignment errors, and rework. Over time, this yields faster maintenance access, fewer cabinet misalignments, and lower lifecycle costs, especially in high-usage environments where enclosure reliability is critical.