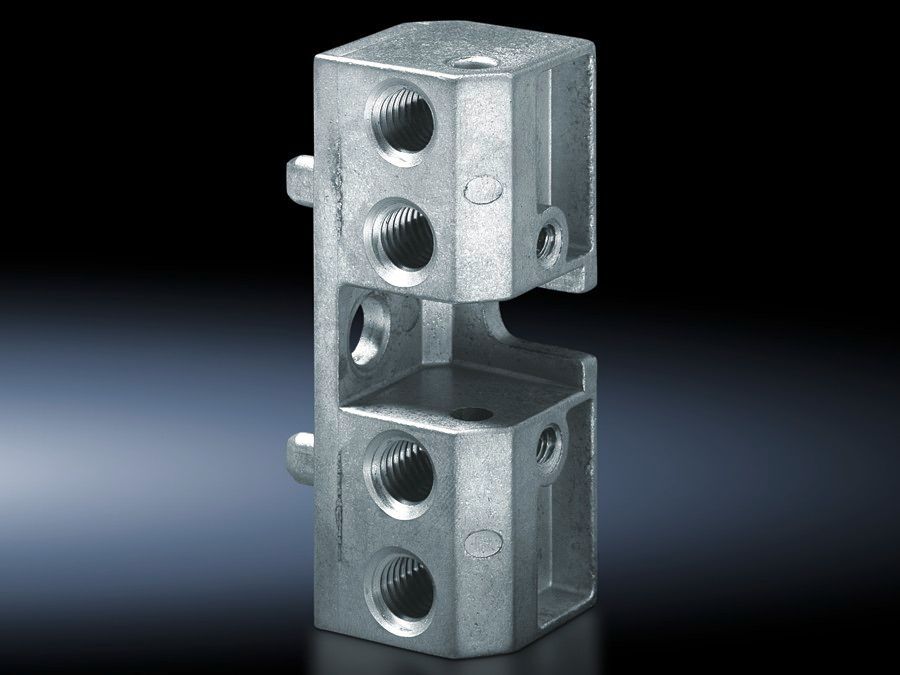

Rittal TS 8800.310 Assembly Block - Die-cast zinc

Part Number: 8800310

Quick Summary

Rittal TS 8800.310 is an assembly block used to mount PS-compatible components in vertical TS, SE enclosure sections. Engineers often grapple with aligning modular parts in tight cabinet spaces, risking misalignment and longer installation times. The block supports ETIM EC002625 and ECLASS 27189234 classifications, helping integrators match data to procurement systems, while relying on precise die-cast zinc construction for durability. For critical environments, the right mounting block reduces maintenance and rework by delivering repeatable fits and robust mechanical stability. This part also simplifies inventory management and installation planning, supporting faster assembly in panel cabinets, with compatibility for PS components and standard TS enclosure architectures.

Product Information

Extended Description

8800310 Rittal: TS Assembly block

Article number

TS 8800.310

Product description

Installation in the vertical TS, SE enclosure sections for mounting PS-compatible individual components.

Material

Die-cast zinc

Supply includes

Assembly screws

Packs of

4 pc(s).

Weight/pack

0.436 kg

Customs tariff number

94039910

EAN

4028177212688

ETIM 9

EC002625

ECLASS 8.0

27189234

Product description

TS Assembly block

Die-cast zinc construction delivers robust mechanical strength, reducing vibration and wear for improved uptime and lower replacement costs in harsh industrial environments. This translates to more reliable PS-compatible component mounting in vertical TS enclosures and fewer field adjustments. Includes assembly screws means technicians can complete installs without sourcing extra parts, shortening project timelines and reducing procurement complexity. Packs of four, with a weight of 0.436 kg per pack, enable predictable inventory planning and more efficient freight and warehouse management. The mounting block is designed for PS-compatible components in vertical TS/SE sections, promoting standardized assembly, faster design cycles, and better interchangeability across projects. Compliance and data integrity are supported by provided classifications and identifiers (ETIM EC002625, ECLASS 27189234, EAN 4028177212688), simplifying ERP integration and supplier qualification.

Get a Quick Quote for a Rittal 8800310

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 8800310?

Enquire Now

FAQs

The TS 8800.310 Assembly Block is designed for installation in vertical TS, SE enclosure sections to mount PS-compatible components. It is intended for use with standard TS enclosure systems and ships with assembly screws, offering a straightforward fitment path and consistent component alignment across projects.

Key specs include Article number TS 8800.310, material die-cast zinc, supply includes assembly screws, packs of 4, weight per pack 0.436 kg, customs tariff 94039910, EAN 4028177212688, ETIM EC002625, and ECLASS 27189234. The product is described as a TS Assembly block for mounting PS-compatible components.

Yes. The TS 8800.310 Assembly Block is specifically designed to mount PS-compatible components within vertical TS/SE enclosure sections, delivering a standardized, repeatable mounting solution that reduces alignment errors and supports easy integration with PS-compatible modules.

As a mounting accessory, ensure the final enclosure assembly meets applicable CE and IP-related requirements based on the enclosure and environment. The block provides standardized data identifiers (ETIM EC002625, ECLASS 27189234) to help with compliance documentation and procurement, but final regulatory conformity depends on the complete system configuration.

The block reduces installation time with included assembly screws, lowers misalignment risk through rigid die-cast zinc construction, and simplifies inventory with packs of four. These factors collectively shorten project cycles, minimize on-site adjustments, and lower maintenance and replacement costs over the system’s lifecycle.