Rittal TS 8800.680 EMC Gland Plate - Shielded Cable

Part Number: 8800680

Quick Summary

Rittal TS 8800.680 EMC gland plate provides shielded-cable entry for 800 mm enclosures. Without proper EMC grounding, shielded cables can cause interference and costly field rework. In typical industrial installations, CE expectations apply and standard IP protection is not supported by this accessory. It is designed to integrate with TS enclosures and standard gland plates, simplifying wiring tasks while maintaining reliable EMI performance. By delivering low-resistance shield contact and including essential components, this gland plate supports faster commissioning and lower lifecycle costs for automation projects.

Product Information

Extended Description

8800680 Rittal: TS EMC gland plate, W: 800 mm

Article number

TS 8800.680

Product description

For shielded cables with a maximum diameter of 20 mm. Combined EMC contacting and cable fastening provide low-resistance contact between the cable shield and gland plate. For all 400, 500, 600 and 800 mm deep enclosures in conjunction with standard gland plates.

Material

Sheet steel

Surface finish

Zinc-plated

Supply includes

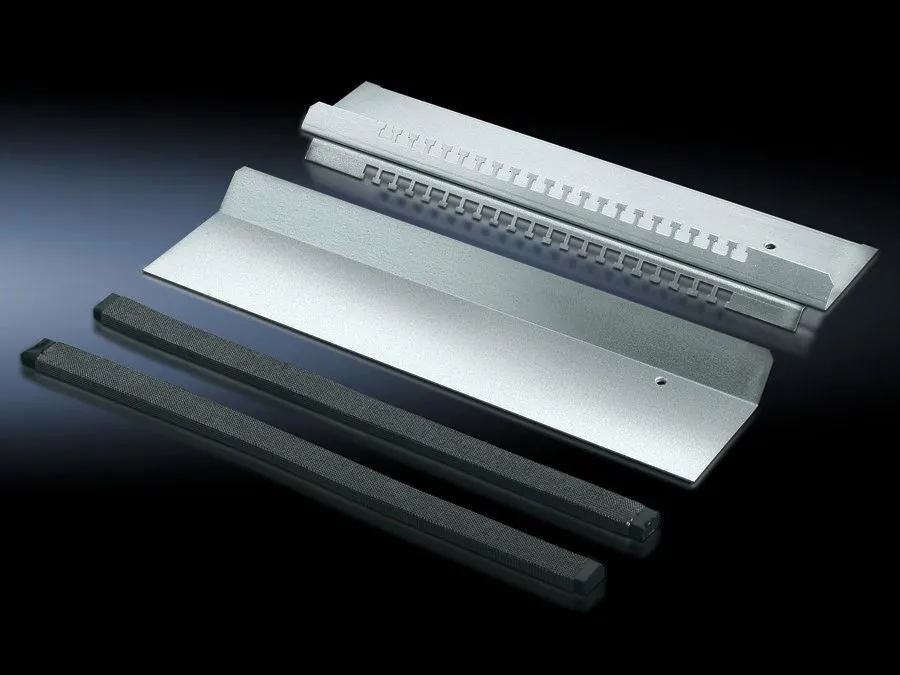

Cable clamp strip with hammer-head punching | 1 sliding gland plate | 2 EMC seals

To fit

Enclosure type: TS | Width: = 800 mm

Note

Standard-compliant IP protection category not supported

Packs of

1 pc(s).

Weight/pack

2.65 kg

Customs tariff number

73269098

EAN

4028177214897

ETIM 9

EC002620

ECLASS 8.0

27189261

Product description

TS EMC gland plate, W: 800 mm

EMC contact design provides a low-resistance path between the cable shield and the gland plate, delivering improved EMI performance. The business impact is greater signal integrity in drives, servo axes, and fieldbus networks, which reduces interference during start-up and lowers the risk of costly rework. The application focuses on shielded cables up to 20 mm diameter in TS enclosures across 400 to 800 mm depths. Material and finish are sheet steel with a zinc-plated surface, delivering durability and corrosion resistance that extend service life and reduce maintenance costs in harsh factory environments. This accessory includes a cable clamp strip with hammer-head punching, one sliding gland plate, and two EMC seals, simplifying procurement and speeding on-site assembly. Compatibility with TS enclosures and standard gland plates enables straightforward integration and consistent EMC sealing, while the 800 mm width and pack weight of 2.65 kg aid handling and installation efficiency. Note that standard IP protection is not supported by this gland plate; for IP-rated protection, pair with appropriately sealed enclosures or gland plates to meet your application’s compliance requirements.

Get a Quick Quote for a Rittal 8800680

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 8800680?

Enquire Now

FAQs

TS 8800.680 is designed to fit TS enclosures with depths of 400, 500, 600, and 800 mm. When selecting this gland plate, verify the enclosure depth to ensure compatibility with the standard gland plates and the included components.

The package includes a cable clamp strip with hammer-head punching, 1 sliding gland plate, and 2 EMC seals. This bundle is intended to streamline installation by providing the essential EMC and fastening components in one purchase.

The gland plate supports shielded cables with a maximum diameter of 20 mm. This makes it suitable for common shielded power and control cables used in TS enclosure installations.

No. The note specifies that standard-compliant IP protection category is not supported by this gland plate. For IP-rated protection, pair this accessory with IP-rated enclosures or gland plates as required by the installation site.

The design provides a low-resistance contact between the shield and gland plate, reducing EMI leakage and improving signal integrity. It also simplifies procurement with included components, speeds up assembly, and ensures consistent EMC sealing across cables, benefiting automation projects and machine-building applications.