Rittal 9345015 Fuseholder - Class J UL 248-8

Part Number: 9345015

Manufacturer

Rittal

Part number

9345015

Category

Alt Part Number

SV 9345.015

Quick Summary

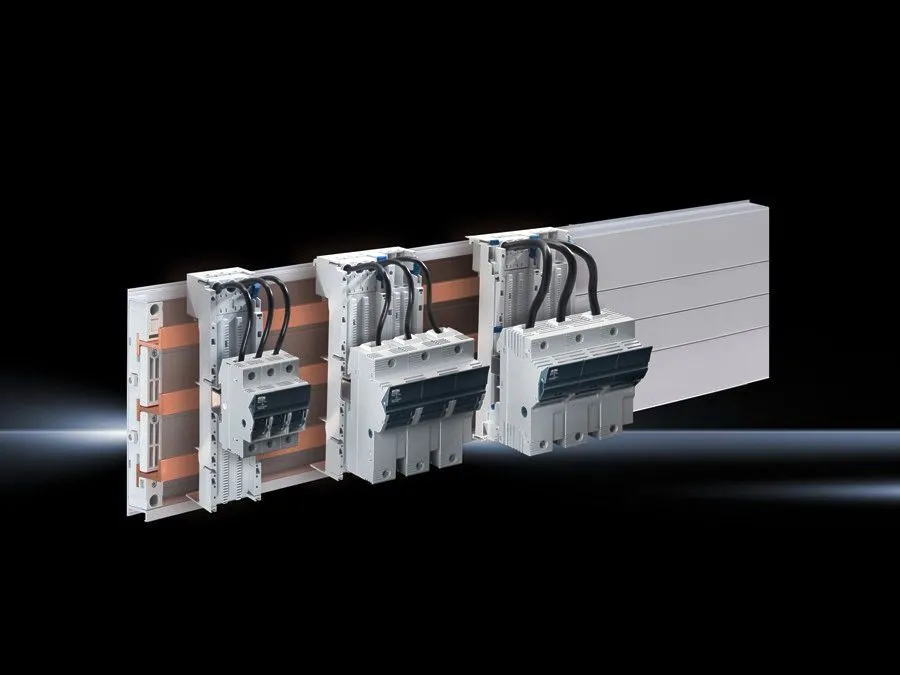

Rittal 9345015 fuseholder is a 3-pole Class J device designed to protect and power distribution in control cabinets. The design targets fast, reliable wiring and easy integration into existing 35 mm DIN rails or RiLine component adaptor configurations, reducing panel wiring time. It carries UL 248-8 fuse compatibility and UL 4248-1 test coverage, with fire-retardant polyamide material rated to UL 94-V0 for safety in demanding environments. In practice, this means streamlined installation, improved reliability, and compliance across industrial automation applications. By combining snap-on mounting with broad wire termination options and robust electrical ratings, it delivers a scalable solution for modern power management and distribution needs.

Product Information

Extended Description

9345015 Rittal: SV Fuseholder, Class J, 30 A, 600 V, 3-pole, (60 mm)

Article number

SV 9345.015

Material

Polyamide | Fire protection corresponding to UL 94-V0

Colour

RAL 7035

Connection for round conductor

AWG 1 - 18

For fuse type (class)

J

Rated operating current max.

30 A

Fuse standard

UL 248-8

Note

For snap-on mounting on 35 mm (7.5 mm/15 mm high) support rails to DIN EN 60 715 or RiLine component adaptor combinations (OM adaptors/supports)

Test specification

UL 4248-1

Dimensions

Width: 108 mm | Height: 115 mm

Connection for round conductor

1.5 ‐ 50 mm²

To fit fuses

Diameter: 21 mm | Length: 57 mm

Voltage range for indicator lights

110 ‐ 600 V

Rated operating voltage

600 V, 3~

Electrical ratings UL (SCCR)

200 kA - 600 V, Fuse Class J max. 30 A, JDDZ/7

Number of poles

3-pole

Packs of

2 pc(s).

Weight/pack

0.966 kg

Copper weight (kg per piece)

0.072

Customs tariff number

85361090

EAN

4028177805392

ETIM 9

EC001900

ECLASS 8.0

27400613

Product description

SV Fuseholder, Class J, 30 A, 600 V, 3-pole, (60 mm)

Feature → Business Impact → Application: The SV 9345.015 fuseholder provides 3-pole Class J protection and supports up to 30 A, enabling compact, reliable protection in 600 V systems for control cabinets and distribution panels. This translates to improved safety margins and compliance with UL 248-8, while maintaining a cost-effective footprint for legacy builds and new panel designs. Feature → Business Impact → Application: It offers snap-on mounting on 35 mm DIN rails or RiLine adaptor configurations, reducing installation time and field wiring errors in machine builders and panel shops. Application includes quick retrofits or upgrades in existing switchgear assemblies, particularly where RiLine components are standard. Feature → Business Impact → Application: The ability to connect round conductors AWG 1–18 (and 1.5–50 mm²) supports diverse wire sizes, enabling flexible harnessing and cleaner panel layouts in automation cabinets. Feature → Business Impact → Application: The fuseholder accommodates 21 mm diameter by 57 mm length fuses, ensuring compatible fuse inventory and straightforward stock management, which lowers maintenance costs and simplifies spares logistics. Feature → Business Impact → Application: With a 110–600 V indicator lights range and a 600 V rated operating voltage, the unit supports accurate status indication and safe operation across single- and three-phase power distribution schemes in manufacturing, packaging, and process industries. Feature → Business Impact → Application: The compact dimensions (Width 108 mm, Height 115 mm) and a weight of 0.966 kg per pack enable efficient panel real estate planning and easier handling during installation, especially in compact control enclosures or retrofits. Feature → Business Impact → Application: UL 4248-1 test compliance and UL SCCR up to 200 kA at 600 V provide confidence for high-short-circuit environments, making this fuseholder suitable for critical line-side protections in robotics, material handling, and packaging lines. Feature → Business Impact → Application: Material choices include polyamide with UL 94-V0 fire resistance, enhancing safety and reducing risk in environments with elevated heat or arc-flash considerations, a crucial factor for industrial safety programs and CE-related expectations as applicable.

Get a Quick Quote for a Rittal 9345015

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9345015?

Enquire Now

FAQs

The SV 9345.015 is designed for snap-on mounting on 35 mm DIN rails (7.5 mm and 15 mm high) or RiLine adaptor combinations. To install, simply align with the rail, press until it snaps securely, and then connect AWG 1–18 or 1.5–50 mm² conductors. Ensure proper clearance for fuse access and verify UL Wire sizing and safety clearances per your panel guidelines.

This fuseholder is configured for Class J fuses with a 21 mm diameter and 57 mm length. Use UL 248-8 class J fuses rated up to 30 A for 600 V systems. Confirm fuse dimensions before installation and ensure the fuse type matches the device’s current rating and the load profile of the protected circuit.

Yes, the SV 9345015 is rated for 600 V, 3-phase applications with a rated operating voltage of 600 V and a voltage range for indicator lights of 110–600 V. This makes it suitable for machine control panels and distribution blocks where reliable visual status indication is required under diverse operation conditions.

The fuseholder supports UL (SCCR) up to 200 kA at 600 V, with three poles and Class J fuse protection. For high-short-circuit environments, ensure your system design considers the 200 kA SCCR rating and proper coordination with upstream protection devices. This helps maintain system integrity and compliance in demanding industrial applications.

Use RiLine adapters or standard 35 mm DIN rails for mounting to minimize install time and ensure mechanical stability. Verify conductor sizes (AWG 1–18 or 1.5–50 mm²), confirm fuse compatibility (21 mm diameter, 57 mm length, Class J), and check material UL 94-V0 fire rating. Regularly inspect connections for tightness and use proper torque values per manufacturer guidelines to maintain long-term reliability.