Rittal 9640370 Terminal Stud - M12 x 30 mm

Part Number: 9640370

Manufacturer

Rittal

Part number

9640370

Category

Alt Part Number

SV 9640.370

Quick Summary

Rittal 9640370 terminal stud is a secure cable connector ideal for Maxi-PLS busbar installations in control cabinets. Engineers often wrestle with loose ring-terminal connections, vibration-induced wear, and tight installation spaces that slow commissioning. The design is compatible with Maxi-PLS 45 S/45 busbars and uses a zinc-plated steel terminal stud with a copper alloy sliding block, aligning with ETIM 9 EC002498 and ECLASS 8.0 27379201 for procurement. By delivering robust mounting and easy assembly, this solution reduces field rework and maintenance overhead while improving reliability in power management and distribution tasks.

Product Information

Extended Description

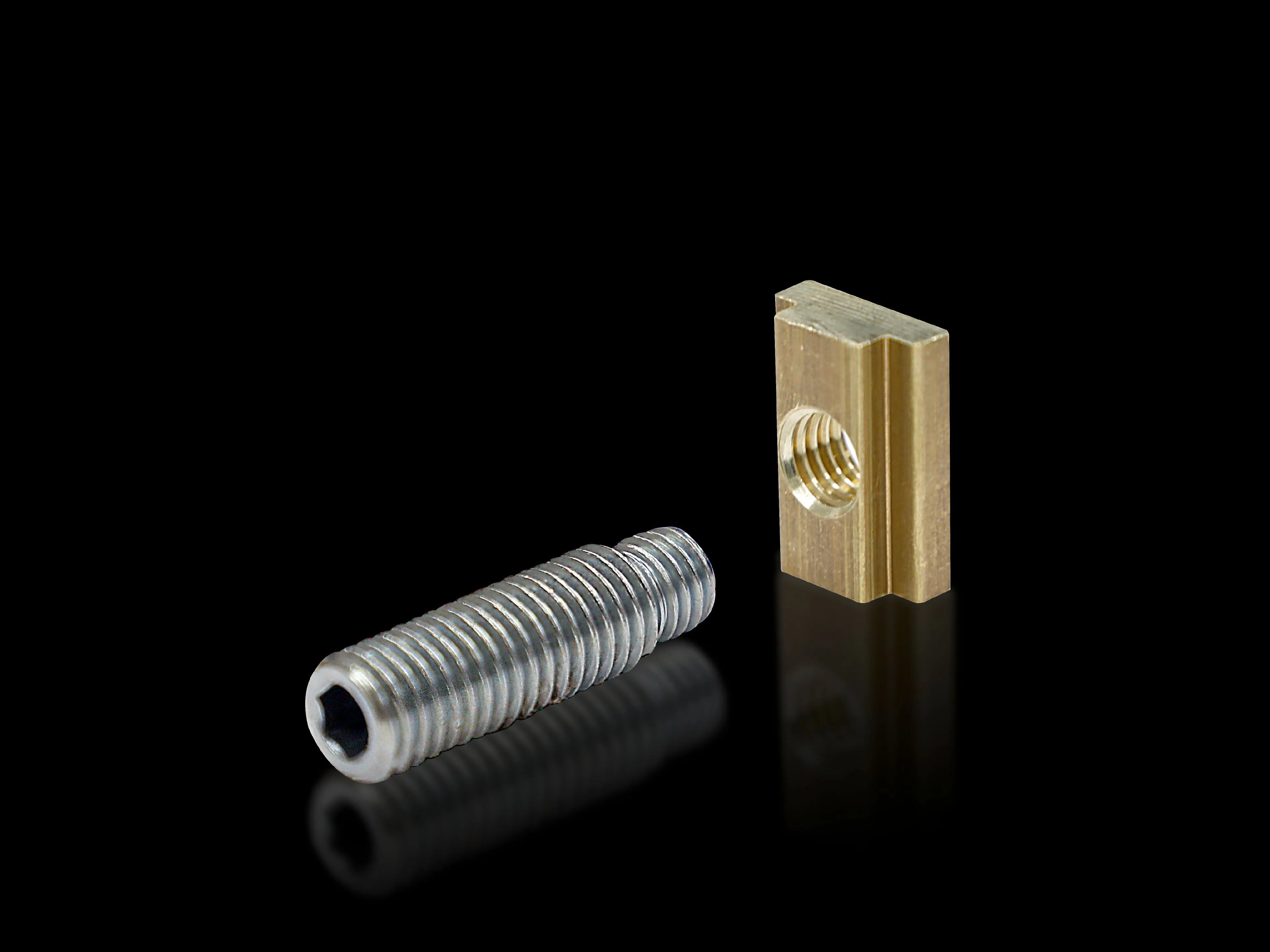

9640370 Rittal: SV Terminal stud, M12, L: 30 mm, (Maxi-PLS 1600/2000)

Article number

SV 9640.370

Product description

For connecting cables with ring terminals.

Material

Terminal stud: Steel, zinc-plated | Sliding block: Copper alloy

Supply includes

Terminal studs | Sliding blocks | Assembly parts

To fit busbars

Maxi-PLS 45 S/45

Dimensions

Thread: M12 | Thread length: 30 mm

Packs of

3 pc(s).

Weight/pack

0.207 kg

Customs tariff number

74198090

EAN

4028177238701

ETIM 9

EC002498

ECLASS 8.0

27379201

Product description

SV Terminal stud, M12, L: 30 mm, (Maxi-PLS 1600/2000)

Feature: Terminal stud material and finish is steel with zinc plating, and sliding block is copper alloy. Business Impact: Enhances corrosion resistance and durable electrical contact, reducing maintenance frequency. Application: Ideal for harsh industrial environments where long-term reliability is required for cable terminals and busbar connections. Feature: Threaded M12 with 30 mm thread length ensures a secure, repeatable connection. Business Impact: Consistent torque and tight clamping improve signal integrity and reduce risk of loosening under vibration. Application: Suitable for control cabinets and power distribution in machinery. Feature: Supply includes terminal studs, sliding blocks, and assembly parts. Business Impact: Streamlined installation with fewer sourcing steps and faster commissioning. Application: Great for projects needing rapid on-site assembly and reduced downtime. Feature: Maxi-PLS 45 S/45 compatibility. Business Impact: Seamless integration with common Maxi-PLS busbar systems, lowering integration risk. Application: Power management and distribution in standard Rittal enclosures. Feature: Packs of 3 with weight 0.207 kg per pack facilitate inventory management. Business Impact: Simplified stock control and predictable reorder cycles. Application: Procurement planning for maintenance and new installations.

Get a Quick Quote for a Rittal 9640370

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9640370?

Enquire Now

FAQs

Yes. The SV 9640.370 is designed to fit Maxi-PLS busbars, specifically Maxi-PLS 45 S/45, enabling straightforward integration with existing enclosure layouts and minimizing the need for adapters or alterations during installation.

Key specs include a thread of M12 with a thread length of 30 mm. The terminal stud is made from zinc-plated steel, and the sliding block is copper alloy, delivering durable electrical contact and resistance to corrosion in demanding environments.

This terminal stud is used to connect cables with ring terminals in control cabinets and power distribution applications, supporting reliable ring-terminal connections in industrial wiring and equipment panels.

The product data references ETIM 9 EC002498 and ECLASS 8.0 27379201 for classification and procurement. Explicit CE, IP, or SIL certifications are not listed in the provided data; verify with the supplier datasheet for any regulatory marks required in your region.

Because the assembly includes terminal studs, sliding blocks, and assembly parts, the product supports faster field installation and easier future maintenance. The zinc-plated steel and copper alloy components provide long-term reliability, reducing rework, spare part churn, and downtime in power-management tasks.