Rittal SV 9650.191 Longitudinal Connector - Maxi-PLS 60

Part Number: 9650191

Manufacturer

Rittal

Part number

9650191

Category

Alt Part Number

SV 9650.191

Quick Summary

Rittal SV 9650.191 Longitudinal Connector enables simple baying of Maxi-PLS busbars in industrial enclosures. In practice, installers face time-consuming alignment and bolt loosening that can degrade current paths. Note: the data provided lists ETIM EC002525 and ECLASS 27400613 classifications but does not specify CE, SIL, or IP ratings—verify the official datasheet for regulatory confirmation in your region. This connector supports modularity and standardized procurement across panels, helping reduce stock diversity. By leveraging the Maxi-PLS ecosystem, you gain quicker commissioning and improved reliability, while maintaining compatibility with existing Maxi-PLS hardware and installation practices.

Product Information

Extended Description

9650191 Rittal: SV Longitudinal connector E-Cu, for Maxi-PLS busbar, Maxi-PLS 3200

Article number

SV 9650.191

Applications

For simple baying connection of Maxi-PLS busbars

Material

E-Cu

Supply includes

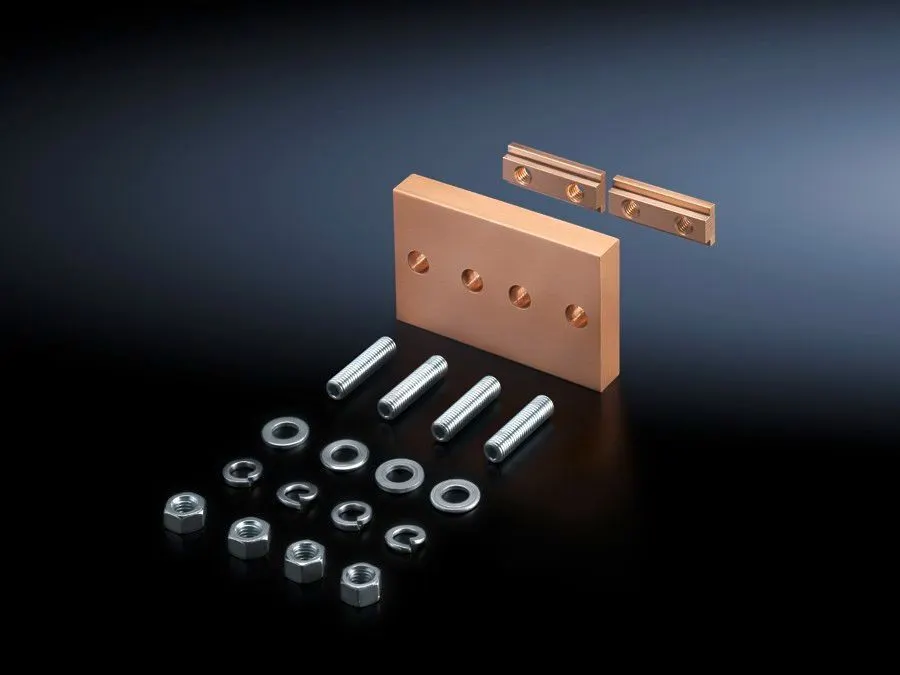

Longitudinal connectors | Sliding blocks | Bolts | Assembly parts

To fit busbars

Maxi-PLS 60

Packs of

1 pc(s).

Weight/pack

2.22 kg

Copper weight (kg per piece)

1.87

Customs tariff number

74198090

EAN

4028177643048

ETIM 9

EC002525

ECLASS 8.0

27400613

Product description

SV Longitudinal connector E-Cu, for Maxi-PLS busbar, Maxi-PLS 3200

Feature: E-Cu material provides low contact resistance and robust conductor surfaces. Benefit: Improves electrical reliability and reduces overheating risk in high-current baying across Maxi-PLS 60 busbars. Application: Ideal for energy distribution cabinets and industrial enclosures where dependable busbar connections are critical. Feature: Supply includes longitudinal connectors, sliding blocks, bolts, and assembly parts. Benefit: Speeds up installation, minimizes sourcing steps, and lowers project lead times. Application: Streamlined field assembly in panel builds and modular switchgear where installation efficiency matters. Feature: Designed to fit Maxi-PLS 60 busbars. Benefit: Ensures precise fit and consistent electrical contact across modules, reducing rework and warranty calls. Application: Suitable for scalable systems in manufacturing lines and distribution panels. Feature: Packs of 1 piece with weight per pack 2.22 kg and copper weight 1.87 kg per piece. Benefit: Predictable shipping, handling, and performance metrics; supports accurate BOM planning. Application: Procurement and logistics workflows in mid-to-large automation projects. Feature: ETIM 9 EC002525 and ECLASS 8.0 27400613 classification alignment. Benefit: Improves supplier data quality, enables accurate procurement searches, and supports compliance management. Application: Industrial procurement databases and ERP integrations for engineering teams.

Get a Quick Quote for a Rittal 9650191

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9650191?

Enquire Now

FAQs

The SV 9650.191 is designed to fit Maxi-PLS 60 busbars and ships with longitudinal connectors, sliding blocks, bolts, and assembly parts to simplify mounting in Rittal enclosures. It supports modular busbar configurations and is intended for use within Maxi-PLS based distribution systems.

Constructed from E-Cu, the connector provides low contact resistance and durable copper contact surfaces, minimizing voltage drop and heating across bayed sections. This translates to more reliable current paths in Maxi-PLS busbar installations and reduces maintenance needs in high-demand enclosures.

The provided data lists ETIM 9 EC002525 and ECLASS 8.0 27400613 classifications but does not explicitly specify CE, SIL, or IP ratings. For regulatory compliance, confirm the official datasheet or contact the supplier to obtain the latest certification details for your region.

The package includes longitudinal connectors, sliding blocks, bolts, and assembly parts, designed to minimize separate sourcing. This reduces installation time, ensures consistent fasteners, and supports a clean, repeatable assembly process across Maxi-PLS 60 baying configurations.

By enabling quick baying of Maxi-PLS busbars with proven copper contact surfaces and a complete hardware kit, maintenance intervals can be extended, commissioning time decreases, and downtime risk reduces during panel expansion or retrofits. This translates to lower labor costs and improved system uptime in automated environments.