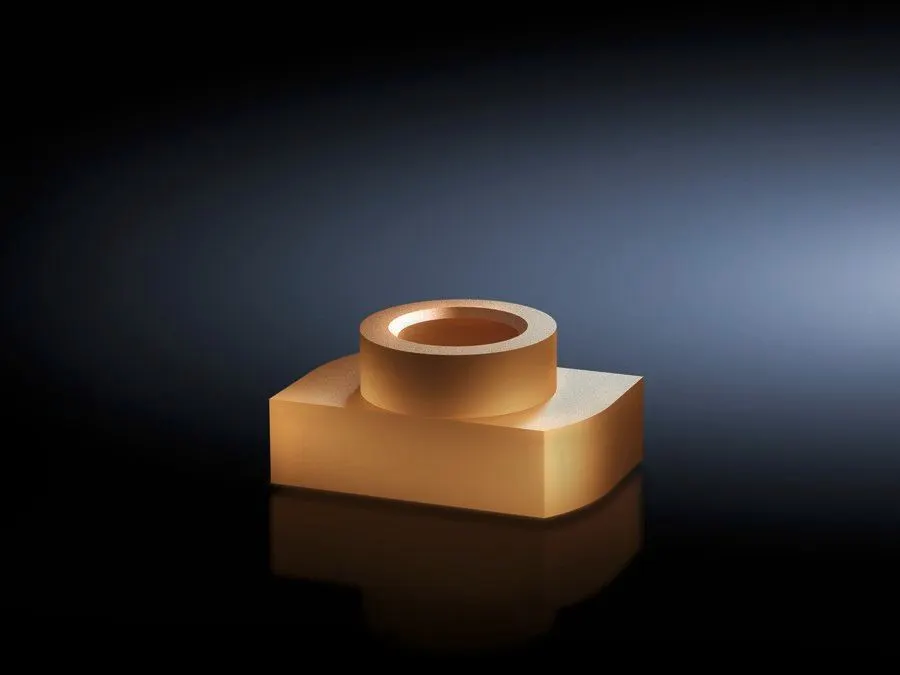

Rittal 9650920 SV Sliding Nut M12 - Maxi-PLS 60

Part Number: 9650920

Manufacturer

Rittal

Part number

9650920

Category

Alt Part Number

SV 9650.920

Quick Summary

SV Sliding nut M12 for Maxi-PLS busbars securely attaches flat copper bars and connection components in electrical switchgear. Retrofits into existing Maxi-PLS sections can be time-consuming and error-prone without a designed retrofit path. The data reflects ETIM EC002525 and ECLASS 23110804 classifications, while material is E-Cu, supporting reliable electrical contact. Designed for cost-effective maintenance, it enables quick installation and dependable copper-bar connections, reducing downtime and inventory complexity. This solution supports Maxi-PLS 60 fitment, accepts standard M12-threaded hardware, and is packaged in 15-piece packs for predictable stocking. In volatile environments, the copper design ensures durable contact quality and minimizes maintenance intervals.

Product Information

Extended Description

9650920 Rittal: SV Sliding nut, M12, (Maxi-PLS 3200)

Article number

SV 9650.920

Product description

For attaching flat copper bars and connection components to Maxi-PLS busbars. For sliding into the busbar section retrospectively and tightening the threaded bolts.

Material

E-Cu

To fit busbars

Maxi-PLS 60

Dimensions

Thread: M12

Packs of

15 pc(s).

Weight/pack

0.255 kg

Customs tariff number

74198090

EAN

4028177239708

ETIM 9

EC002525

ECLASS 8.0

23110804

Product description

SV Sliding nut, M12, (Maxi-PLS 3200)

SV Sliding nut with M12 thread slides into Maxi-PLS busbar sections to attach flat copper bars and connection components. This retrofit capability dramatically reduces commissioning time by eliminating the need to dismantle major assemblies and rework adjacent busbar structures. It is specifically designed to fit Maxi-PLS 60 arrangements and to tolerate the tight tolerances found in modern switchgear, delivering reliable bolt-tightening and consistent contact pressure in demanding environments. Material is E-Cu, chosen for superior electrical conductivity and corrosion resistance, which translates into lower contact resistance and longer service life for copper-bar connections. The nut provides a robust mechanical interface for anchoring copper bars and connection components, supporting stable performance even under vibration, thermal cycling, and panel flexing. With standard M12 threading, engineers can leverage familiar hardware practices, improving installation speed and reducing potential misfits. Packaging in 15-piece packs and a weight of 0.255 kg per pack support predictable stocking and efficient logistics, helping maintenance teams optimize spares inventories and minimize total cost of ownership. The design also facilitates quick replacements during preventive maintenance, reducing downtime and limiting production interruptions. Compatibility is clearly defined for Maxi-PLS 60 busbars, and the retrospective sliding installation avoids costly busbar section removal while enabling future upgrades. The sliding-nut approach reduces field risk during retrofits and improves project timelines by enabling assembly-level changes with minimal tools and training. Bolts tighten with common hand tools, helping field technicians work faster and with fewer specialized fixtures. Procurement and data management are simplified by ETIM EC002525 and ECLASS 23110804 classifications, aligning the product with ERP, catalog, and purchasing workflows. The product description's emphasis on sliding the nut into the Maxi-PLS section retrospectively supports change-management processes in evolving electrical systems. For engineers seeking robust copper-bar connections, this solution delivers a proven blend of electrical performance, mechanical reliability, and installation ease.

Get a Quick Quote for a Rittal 9650920

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9650920?

Enquire Now

FAQs

SV 9650.920 is designed specifically to fit Maxi-PLS 60 busbars, allowing retrospective installation by sliding into the busbar section and securing with M12 bolts. This compatibility minimizes busbar rework and reduces field risk. When planning, confirm busbar width, bolt pattern, and available clearance to ensure a clean retrofit and reliable contact pressure. The 15-piece packing and 0.255 kg weight per pack aid in spare-part planning and stocking for maintenance squads.

Key considerations include the E-Cu material which provides low contact resistance and good corrosion resistance, helping sustain electrical performance over time. The M12 thread supports common bolting practices and reliable torque transfer, ensuring stable connections for flat copper bars and connection components. Ensure the mounting area remains clean and free of oxidation, and verify bolt torque with standard tools to maintain consistent electrical contact under operational loads.

Yes, the E-Cu sliding nut is designed for robust copper-bar connections subject to vibration and thermal cycling typical in control panels and switchgear. The M12 threaded fastening provides a secure mechanical interface, while the copper contact surface maintains low resistance. For harsher environments, inspect mounting integrity after commissioning and schedule periodic torque checks to sustain reliable performance.

Procurement and data management are supported by ETIM EC002525 and ECLASS 23110804 classifications, aligning the product with ERP, catalog, and purchasing workflows. The EAN 4028177239708 enables precise item tracking, while the product description notes retrospective insertion into Maxi-PLS sections. Use these references to ensure consistent cataloging, compatibility checks, and compliant integration into existing electrical-system projects.

Best practices include sliding the nut into the Maxi-PLS 60 busbar section first, aligning the M12 threaded holes with the bolt pattern, and tightening bolts with a standard Allen/hex key to the appropriate torque. Clean contact surfaces prior to assembly, verify bolt alignment, and perform a torque check after initial energization. Keep the 15-piece pack organization for rapid replacements during preventive maintenance to minimize downtime.