Rittal 9661040 SV Busbar E-Cu - 40x10 mm Copper Busbar EC002525

Part Number: 9661040

Quick Summary

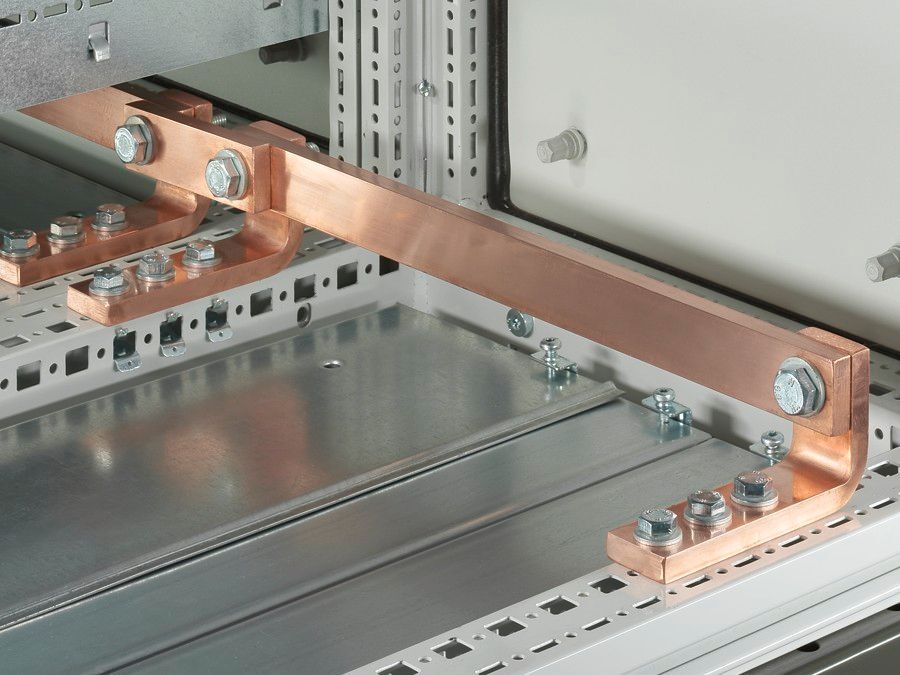

SV Busbar E-Cu is designed for direct installation in enclosures to support robust power distribution. Installers in crowded control panels often battle misalignment, loose contacts, and corrosion risk that slow projects. The product references ETIM 9 EC002525 and ECLASS 8.0 27400605 to ensure interoperability and streamlined procurement. Its 40x10 mm cross-section, 392 mm length, and Ø14 mm mounting holes align with standard busbar supports for quick, compliant installation. With a two-pack design and copper weight of 1.38 kg per piece, you gain predictable performance and reduced maintenance, saving time and costs.

Product Information

Extended Description

9661040 Rittal: SV Busbar E-Cu, WH: 40x10 mm, L: 392 mm, with integral holes Ø 14 mm

Article number

SV 9661.040

Product description

Suitable for direct installation in enclosures, busbar supports 9340.000/.010. 9340.004, 9342.014, 3052.000 and 3073.000. PE/PEN combinations in conjunction with PE/PEN combination angle and baying bracket E-Cu.

Material

E-Cu

Ø hole

14 mm

Dimensions

Length: 392 mm

To fit

Width: = 400 mm

Cross-section

10 mm x 40 mm

Packs of

2 pc(s).

Weight/pack

6.5 kg

Copper weight (kg per piece)

1.38

Customs tariff number

74071000

EAN

4028177555761

ETIM 9

EC002525

ECLASS 8.0

27400605

Product description

SV Busbar E-Cu, WH: 40x10 mm, L: 392 mm, with integral holes Ø 14 mm

Direct enclosure installation reduces on-site assembly time and accelerates commissioning by providing a ready-to-mount copper busbar. The 40x10 mm cross-section ensures a consistent conductive path, improving current handling and contact reliability, which translates to fewer field adjustments and lower risk of overheating. Ø14 mm mounting holes offer versatile positioning and compatibility with common enclosure mounting hardware, enhancing installation flexibility in varied panel layouts. Material selected as E-Cu delivers excellent conductivity with superior corrosion resistance, extending service life in challenging environments and reducing maintenance interventions. Packaging as two pieces per pack supports scalable deployments in growing facilities and simplifies stocking for procurement teams, contributing to lower total cost of ownership. Compatibility with Rittal busbar supports and PE/PEN configurations enables seamless integration into existing systems.

Get a Quick Quote for a Rittal 9661040

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9661040?

Enquire Now

FAQs

Yes. The SV Busbar E-Cu is designed for direct enclosure installation and is compatible with standard Rittal busbar supports, including PE/PEN configurations. It ships as a two-pack and is specified to fit with supports referenced in the product description, ensuring quick, reliable integration in common panel layouts.

Key specifications include a cross-section of 10 mm x 40 mm, a length of 392 mm, and Ø14 mm mounting holes. Copper weight is 1.38 kg per piece, with each pack containing two pieces and a total pack weight of 6.5 kg, enabling predictable performance and balanced handling in assemblies.

The busbar is designed to fit enclosures with a width of 400 mm and a length of 392 mm, featuring integral Ø14 mm holes for flexible mounting. It is compatible with busbar supports and baying brackets used in standard Rittal configurations, including direct installation in enclosures that require PE/PEN combination supports.

The SV Busbar E-Cu references ETIM 9 EC002525 and ECLASS 8.0 27400605 to ensure interoperability and procurement standardization. The product also carries the GTIN 4028177555761 and EAN 4028177555761, along with a customs tariff number of 74071000, supporting regulatory and logistics processes.

Two-piece packs streamline stocking and reduce reordering time, while the robust E-Cu material and precise mounting holes minimize field adjustments and contact reliability issues. This combination lowers commissioning time, minimizes downtime, and reduces lifecycle maintenance costs for panel builders and facilities with frequent enclosure updates.