Rittal 9661060 SV Busbar E-Cu - EC002525

Part Number: 9661060

Quick Summary

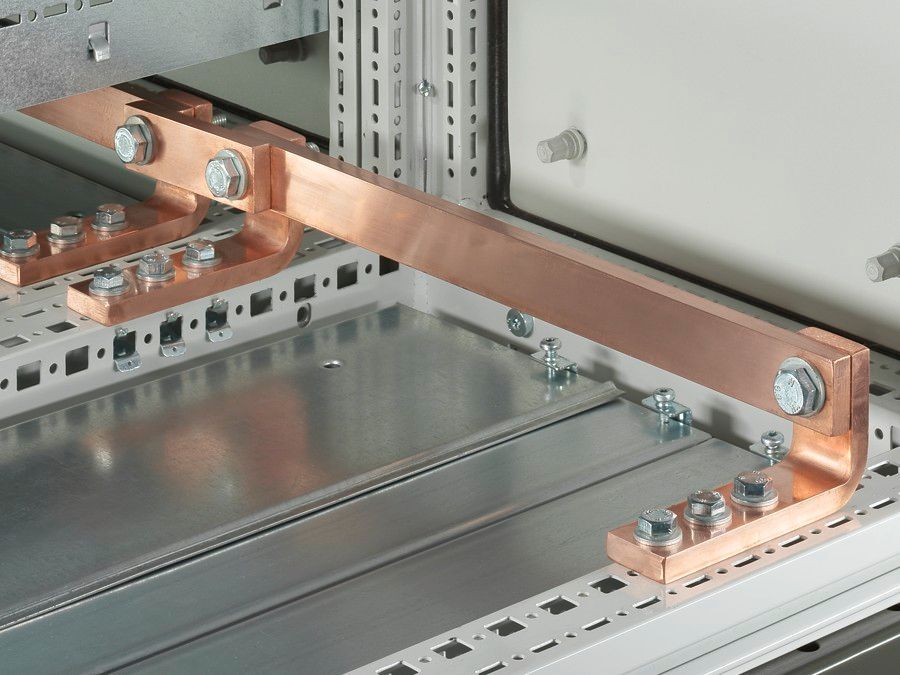

Rittal 9661060 SV Busbar E-Cu is designed for direct installation in enclosures to support busbar systems and PE/PEN combinations. Engineers often face challenges with reliable copper connections in tight spaces, limited access for maintenance, and the need to maintain electrical integrity while minimizing downtime. This solution aligns with ETIM 9 EC002525 and ECLASS 8.0 27400605 classifications, aiding compliance in CE-marked enclosures and standard IP-rated assemblies. By selecting SV Busbar E-Cu, you gain improved conductivity, faster installation, and reduced total installed cost through modular enclosure configurations that scale with your control panels and automation racks.

Product Information

Extended Description

9661060 Rittal: SV Busbar E-Cu, WH: 40x10 mm, L: 592 mm, with integral holes Ø 14 mm

Article number

SV 9661.060

Product description

Suitable for direct installation in enclosures, busbar supports 9340.000/.010. 9340.004, 9342.014, 3052.000 and 3073.000. PE/PEN combinations in conjunction with PE/PEN combination angle and baying bracket E-Cu.

Material

E-Cu

Ø hole

14 mm

Dimensions

Length: 592 mm

To fit

Width: = 600 mm

Cross-section

10 mm x 40 mm

Packs of

2 pc(s).

Weight/pack

4.204 kg

Copper weight (kg per piece)

2.06

Customs tariff number

74071000

EAN

4028177494718

ETIM 9

EC002525

ECLASS 8.0

27400605

Product description

SV Busbar E-Cu, WH: 40x10 mm, L: 592 mm, with integral holes Ø 14 mm

Feature → Business Impact → Application: The SV Busbar E-Cu uses a 40x10 mm cross-section with Ø14 mm holes, delivering high current capacity in compact spaces; this translates to reliable power distribution with minimal voltage drop in narrow enclosures. Application-wise, it fits directly in enclosures and supports busbar systems with PE/PEN combination accessories, enabling quicker panel builds and simplified maintenance actually reducing downtime. Feature → Business Impact → Application: Two-pack configuration (Packs of 2) with copper weight of 2.06 kg per piece and total pack weight of 4.204 kg provides predictable handling, safer installation, and easier inventory planning in assembly lines and field installations. Feature → Business Impact → Application: The length of 592 mm and width compatibility for 600 mm enclosures ensures standardization across control cabinets, improving repeatability in manufacturing and field upgrades. Feature → Business Impact → Application: Integral Ø14 mm mounting holes simplify alignment, enabling robust mechanical connections that resist vibration and thermal cycling in industrial environments. Feature → Business Impact → Application: The E-Cu material offers excellent electrical conductivity and thermal performance, supporting efficiency gains and reduced conductor losses in energy-intensive automation systems.

Get a Quick Quote for a Rittal 9661060

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9661060?

Enquire Now

FAQs

Yes. SV 9661.060 is designed for direct installation in enclosures and is compatible with standard PE/PEN combination accessories and common busbar supports listed in the product description, ensuring straightforward integration into 600 mm wide cabinets.

Key specs include cross-section 10 mm x 40 mm, length 592 mm, and Ø holes of 14 mm. The pack contains 2 pieces with a copper weight of 2.06 kg per piece (4.204 kg per pack), facilitating predictable handling and assembly.

It is designed for direct enclosure installation and supports busbar accessories such as PE/PEN combination angles and baying brackets E-Cu, ensuring seamless integration with enclosure systems and streamlined installation.

The product is cataloged under ETIM 9 EC002525 and ECLASS 8.0 27400605, aligning with data models used for procurement and engineering. While CE marking is standard for enclosure components, confirm regional compliance for your installation.

By enabling direct enclosure mounting, reducing assembly time, and using standardized 2-piece packs with known copper weight, users can reduce installation labor, minimize miswiring, and improve long-term maintenance predictability and energy efficiency in control panels.