Rittal SV 9681.566 VX Roof Plate - ETIM EC000744

Part Number: 9681566

Manufacturer

Rittal

Part number

9681566

Alt Part Number

SV 9681.566

Quick Summary

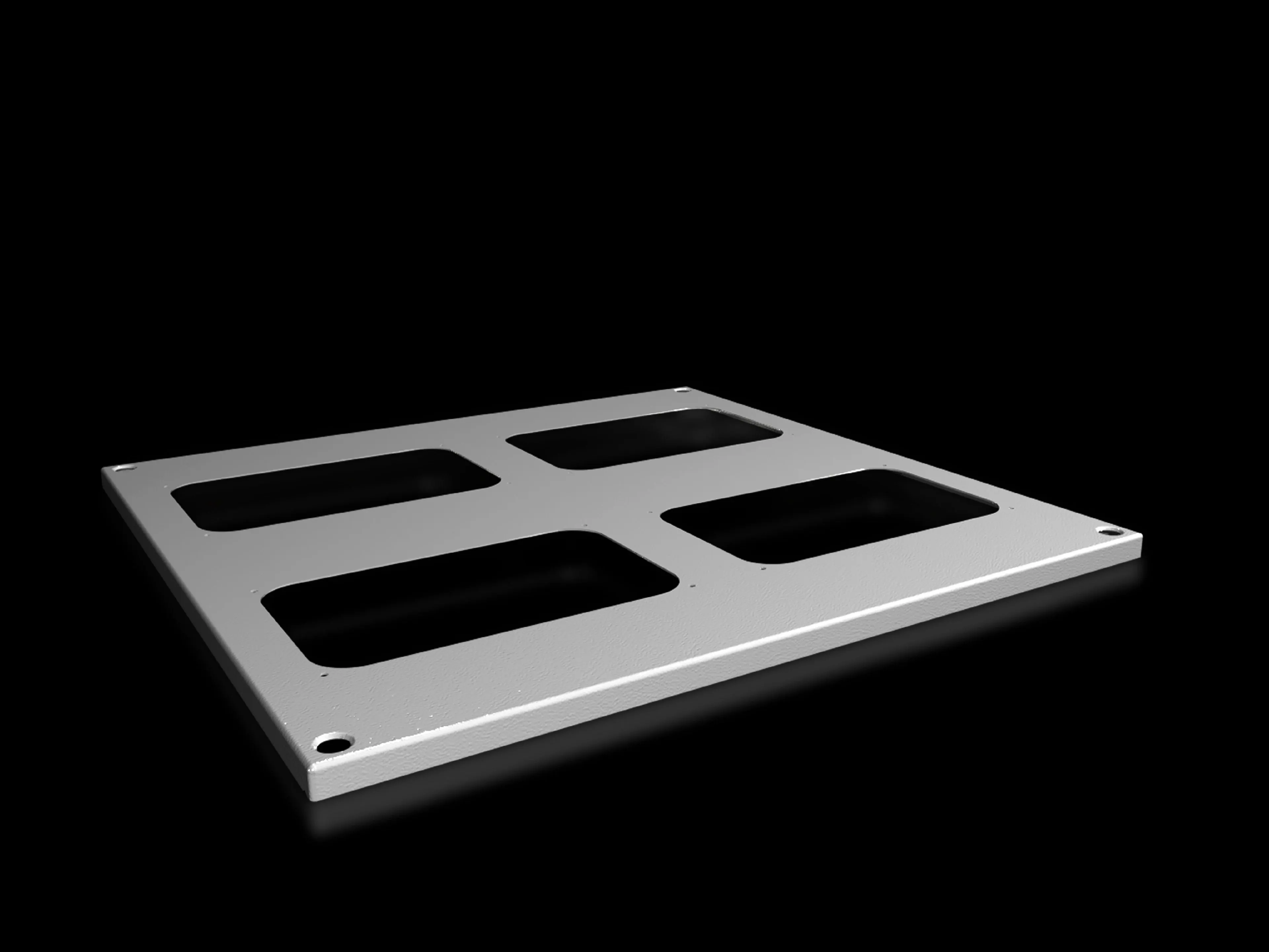

Rittal SV 9681.566 VX Roof Plate provides a replacement roof for 600x600 mm enclosures. When upgrading or retrofitting, unplanned downtime can derail schedules, and a simple roof swap minimizes disruption. Conformance references ETIM EC000744 and ECLASS 27182405 help procurement teams maintain accurate data, while the 1.5 mm sheet steel and textured RAL 7035 finish deliver durable protection in harsh environments. The package includes assembly parts for fast installation, reducing mounting time and service overhead. This roof plate is well suited for data centers, manufacturing lines, and retrofit projects where clean aesthetics and robust performance matter. Its compatibility with four cable entry glands simplifies cabling and preserves enclosure integrity during changes.

Product Information

Extended Description

9681566 Rittal: VX Roof plate, Wdepth 600x600 mm, for cable entry glands

Article number

SV 9681.566

Product description

For enclosures without roof plate and in exchange for the standard roof.

Material

Sheet steel, 1.5 mm

Surface finish

Textured paint

Colour

RAL 7035

Supply includes

Assembly parts

Number of required cable entry glands

4

To fit

Width: = 600 mm | Depth: = 600 mm

Packs of

1 pc(s).

Weight/pack

4 kg

PCF per pack (cradle-to-gate)

15.2 kg CO2 eq (Cat B)

Note on PCF category

Category B: PCF value (cradle-to-gate) based on the product weight, approximately calculated and self-declared

Customs tariff number

73269098

EAN

4028177926608

ETIM 9

EC000744

ECLASS 8.0

27182405

Product description

VX Roof plate, Wdepth 600x600 mm, for cable entry glands

Material and finish deliver durability in demanding environments. The VX Roof Plate uses sheet steel 1.5 mm, finished with textured paint in RAL 7035, providing corrosion resistance and a uniform cabinet appearance after installation. The combination reduces maintenance costs and helps meet long-term reliability targets in industrial settings. The textured surface also hides minor handling marks during installation, contributing to a professional, maintenance-friendly enclosure across fleets. Size and fit deliver predictable installation. With a 600x600 mm footprint and 600 mm depth compatibility, it aligns perfectly with standard VX enclosures, and the included assembly parts streamline mounting. The design supports four cable entry glands, helping maintain a clean, organized cabling layout. This reduces on-site guesswork and the need for adapters, shaving installation time and improving first-pass seal integrity. Weight, packaging, and sustainability. Each pack weighs 4 kg, with a single unit per pack, enabling easy handling and on-site logistics. PCF data show 15.2 kg CO2 equivalent per pack (Category B), helping you compare environmental impact across suppliers and justify retrofit decisions. Material and finish choices also support recycling workflows, aligning with green procurement goals and long-term operational sustainability. Upgrade and retrofit advantages. Replacing or upgrading to this roof plate reduces enclosure downtime and simplifies maintenance. The four-gland configuration supports typical field wiring, while assembly parts ensure consistent fit across units. Pre-aligned mounting points and standard fasteners minimize errors, enabling reliable rollouts when retrofitting multiple cabinets and preserving enclosure ingress protection in demanding environments. Compliance and data integrity. ETIM EC000744 and ECLASS 27182405 classifications support accurate BOMs and procurement workflows. The component carries a customs tariff code 73269098 and EAN 4028177926608, enabling smoother import, stocking, and product traceability within automation supply chains. Clear documentation helps engineers meet internal standards for part replacements and audits, while the packaging and part numbers align with quality control practices across facilities. Operational flexibility. The VX Roof Plate maintains the enclosure’s appearance and ensures reliable sealing against dust and moisture in RAL 7035, while enabling straightforward upgrades and replacements across manufacturing floors, data centers, and harsh environments. Its compatibility with four glands and inclusion of assembly parts gives installers a predictable, repeatable process, supporting scalable rollouts across large facilities.

Get a Quick Quote for a Rittal 9681566

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9681566?

Enquire Now

FAQs

The roof plate is designed specifically for Rittal VX enclosures with a 600x600 mm footprint and 600 mm depth. It ships with assembly parts and supports four cable entry glands, ensuring a precise fit and straightforward installation. This minimizes field modifications, speeds up retrofits, and maintains enclosure integrity during the swap.

The plate uses sheet steel with a thickness of 1.5 mm and a textured paint finish in RAL 7035. This combination delivers robust mechanical protection, weather resistance in industrial environments, and a uniform aesthetic across multiple enclosures, reducing the need for additional cosmetic modifications after installation.

Yes. The VX Roof Plate is spec’d to fit four cable entry glands. This configuration helps maintain an organized cabling layout, preserves seal integrity, and minimizes the need for extra adapters or field modifications during installation.

Explicit CE certification is not listed in the provided data. The component aligns with ETIM EC000744 and ECLASS 27182405 standards, supporting accurate data for BOMs and procurement. It also provides a VOC for import with tariff code 73269098 and EAN 4028177926608, aiding compliance and traceability.

PCF data indicate 15.2 kg CO2 eq per pack (Cat B). The plate weighs 4 kg per pack, and packaging supports single-unit handling. ROI benefits come from reduced downtime, faster installation, and consistent enclosure integrity, which lowers maintenance costs and improves uptime across data centers and manufacturing lines.