Rittal SV 9684.008 Busbars with punchings - DIN EN 13 601

Part Number: 9684008

Manufacturer

Rittal

Part number

9684008

Category

Alt Part Number

SV 9684.008

Quick Summary

Rittal SV 9684.008 busbars with integral punchings enable compact, efficient copper distribution inside electrical enclosures. For engineers facing space constraints and messy wiring, achieving neat, scalable power distribution is a constant challenge. DIN EN 13 601 compliance ensures safe, standardized busbar dimensions and reliable punching patterns. With a cross-section of 50 x 10 mm and a copper weight of 3.48 kg per piece, the part supports high current density with minimal voltage drop. This helps reduce field customization and installation time, while improving reliability across control panels and auxiliary power racks. Designed for compatibility with standard punchings and mounting patterns, it integrates smoothly with existing Rittal systems to streamline procurement.

Product Information

Extended Description

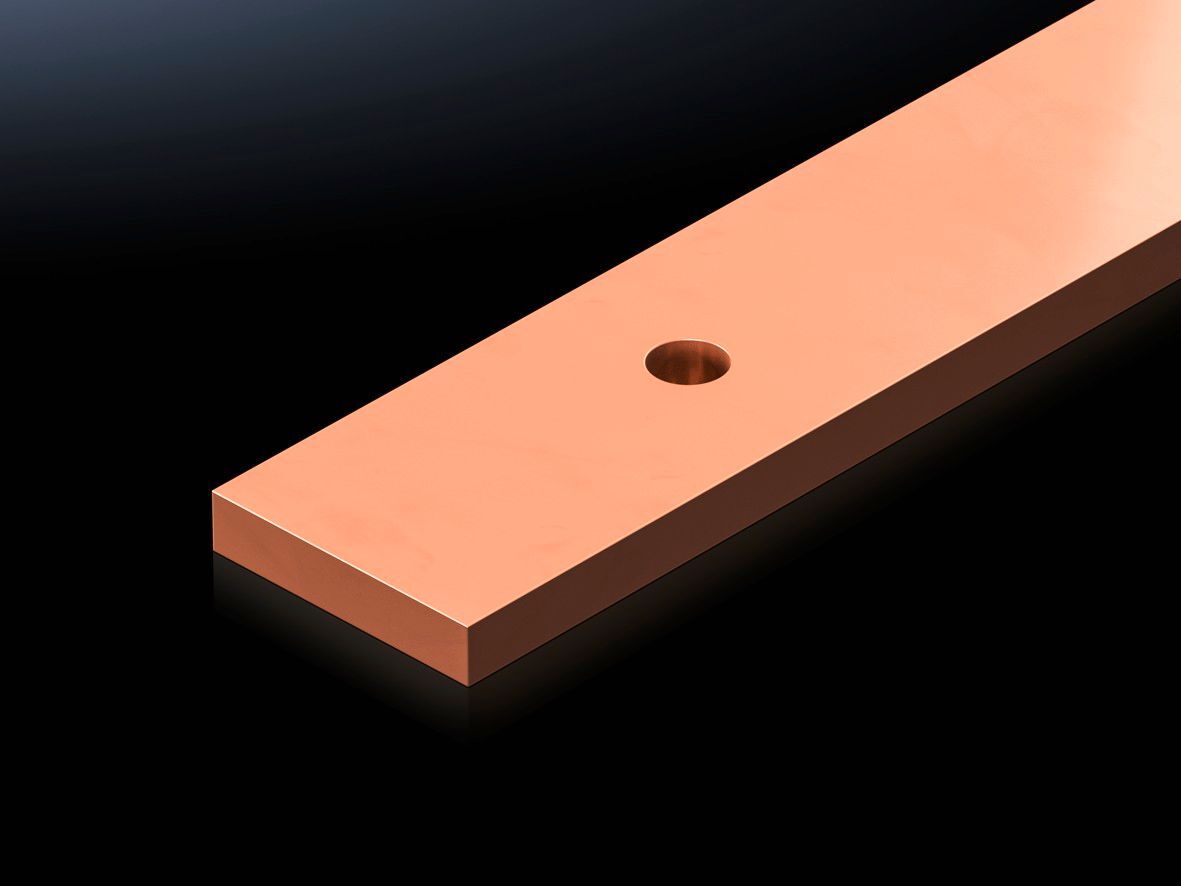

9684008 Rittal: SV busbars E-Cu with integral punchings, length 785 mm

Article number

SV 9684.008

Product description

Busbars with integral punchings.

Material

E-Cu F30

Length

785 mm

Standards

DIN EN 13 601

Cross-section

50 mm x 10 mm

Hole diameter

11.5 mm

Packs of

1 pc(s).

Weight/pack

3.58 kg

Copper weight (kg per piece)

3.48

Customs tariff number

74071000

EAN

4028177951204

ETIM 9

EC001522

ECLASS 8.0

27370303

Product description

SV busbars E-Cu with integral punchings, length 785 mm

E-Cu F30 copper busbars with integral punchings deliver high conductivity and robust mechanical stability, reducing resistance and heat in live cabinets. This translates to higher system efficiency, longer service life, and fewer mid-life failures in harsh industrial environments. The 785 mm length and 50 x 10 mm cross-section reduce the need for splicing and simplify routing in compact enclosures, cutting installation time and minimizing wiring complexity. The 11.5 mm hole diameter enables fast mounting with standard hardware, accelerating on-site assembly and reducing hardware procurement complexity. Compliance with DIN EN 13 601 ensures interoperability across European equipment, lowering procurement risk and easing regulatory validation for cabinet builds. Copper weight of 3.48 kg per piece and a 1 piece per pack packaging strategy support accurate project costing and predictable shipping. ETIM EC001522 and ECLASS 27370303 classifications improve ERP and procurement accuracy, enabling seamless system integration. Designed for compatibility with standard punchings and DIN EN 13 601 mounting patterns, it integrates easily with existing Rittal components to accelerate system upgrades and maintenance.

Get a Quick Quote for a Rittal 9684008

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9684008?

Enquire Now

FAQs

SV 9684.008 is designed around standard punchings and mounting patterns, with a length of 785 mm and a 50 x 10 mm cross-section, plus 11.5 mm holes to fit common hardware. It arrives in packs of one and uses copper weight of 3.48 kg per piece, making it straightforward to spec and install in typical Rittal cabinet configurations.

E-Cu F30 copper provides high electrical conductivity and solid mechanical strength. With a 50 x 10 mm cross-section and 3.48 kg copper per piece, these busbars support efficient current distribution and stable thermal behavior in power cabinets, reducing resistance-related losses and heat buildup.

Yes. The 785 mm length, 50 x 10 mm cross-section, and integral punchings are well-suited for main feeders in electrical cabinets and switchgear, enabling neat routing, fewer field modifications, and reliable, scalable power distribution in industrial environments.

The busbars conform to DIN EN 13 601, and they are classified under ETIM EC001522 and ECLASS 27370303, which aids procurement systems and regulatory validation. These specifications help ensure interoperability and reduce compliance risk in European installations.

Each pack contains 1 piece with a weight of 3.58 kg and copper content of 3.48 kg, simplifying shipping estimates and inventory planning. The standardization reduces field punchings and rework, contributing to lower installation time and predictable project costs over the lifetime of the cabinet system.