Rittal 9684010 Busbars - DIN EN 13 601

Part Number: 9684010

Manufacturer

Rittal

Part number

9684010

Category

Alt Part Number

SV 9684.010

Quick Summary

Rittal 9684010 Busbars enable robust E-Cu power distribution in control cabinets and switchgear. This compact busbar solution delivers reliable copper conductors with integral punchings to simplify assembly. Replacing damaged copper bars or misaligned punchings is costly and time-consuming for panel builds, often delaying projects. The product conforms to DIN EN 13 601 and aligns with ETIM 9 EC001522 and ECLASS 8.0 27370303, helping engineers and buyers secure correct parts in supplier catalogs. By combining high-conductivity E-Cu F30 with precise punching, it streamlines installation, reduces scrap, and improves electrical reliability. For panel builders and machine integrators, this translates into faster commissioning, predictable performance, and lower total cost of ownership.

Product Information

Extended Description

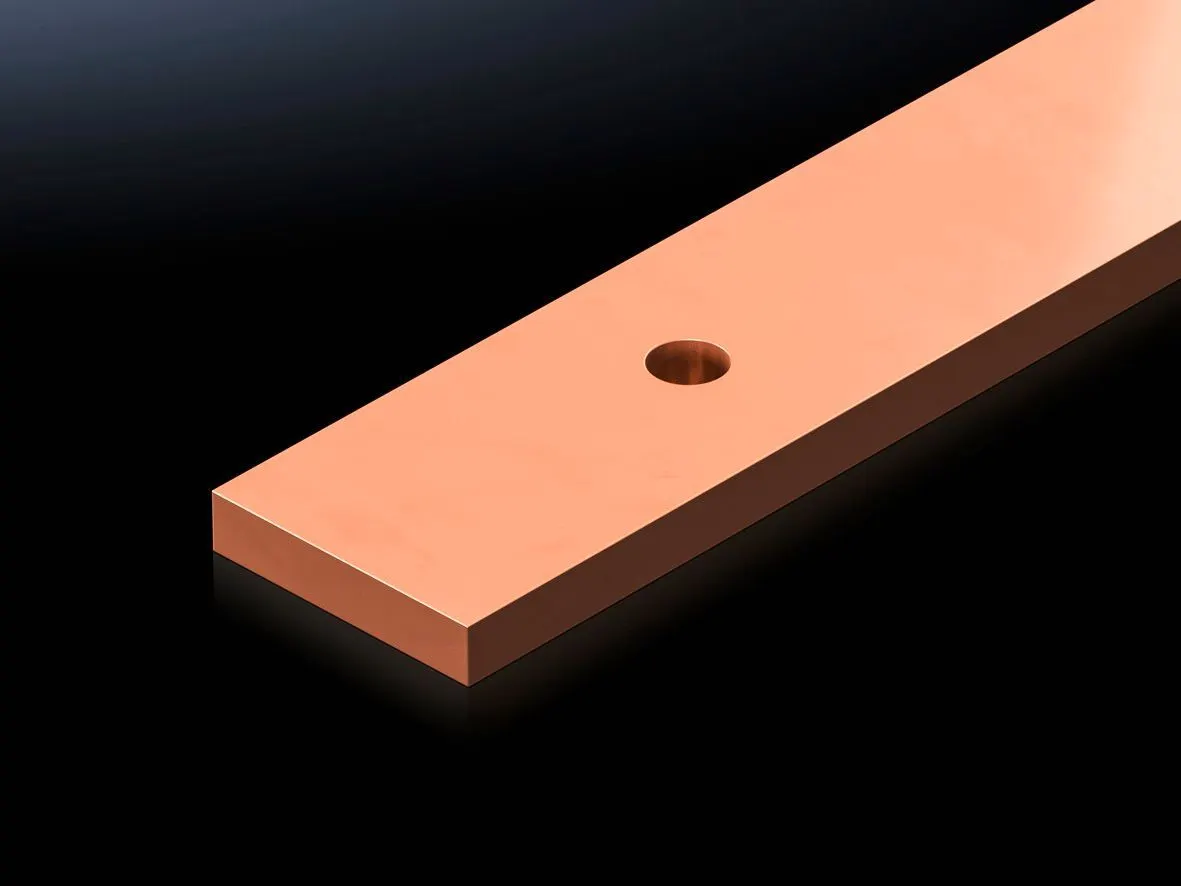

9684010 Rittal: SV busbars E-Cu with integral punchings, length 985 mm

Article number

SV 9684.010

Product description

Busbars with integral punchings.

Material

E-Cu F30

Length

985 mm

Standards

DIN EN 13 601

Cross-section

50 mm x 10 mm

Hole diameter

11.5 mm

Packs of

1 pc(s).

Weight/pack

4.48 kg

Copper weight (kg per piece)

4.38

Customs tariff number

74071000

EAN

4028177951211

ETIM 9

EC001522

ECLASS 8.0

27370303

Product description

SV busbars E-Cu with integral punchings, length 985 mm

Integrated punchings and 11.5 mm holes provide a precise mounting pattern, enabling secure connections and repeatable assembly. Business impact: faster installation, reduced risk of misalignment, and improved contact stability. Application: ideal for control cabinets and modular switchgear where mounting accuracy directly influences current paths and reliability. Copper material is E-Cu F30 with a copper weight of 4.38 kg per piece, and the busbar measures 50 mm x 10 mm with a length of 985 mm. Business impact: low electrical resistance, enhanced current capability, and durable performance in high-current applications. Application: suitable for compact power distribution layouts and long-life installations in industrial automation environments. Each pack contains 1 piece with a total pack weight of 4.48 kg, simplifying inventory and reducing stocking complexity. Business impact: streamlined procurement and predictable lead times. Application: supports just-in-time deliveries for panel shops and assembly lines. DIN EN 13 601 compliance and clear product classification (ETIM 9 EC001522, ECLASS 8.0 27370303) reduce cataloging friction and improve purchasing accuracy. Business impact: faster part selection, lower mismatch risk, and better regulatory alignment. Application: ideal for engineering BOMs and cross-vendor procurement. The 985 mm length, 50x10 mm cross-section, and 11.5 mm hole diameter are designed for compatibility with standard enclosure mounting patterns and fastening hardware. Business impact: minimized rework, consistent electrical paths, and easier future upgrades. Application: supports scalable layouts in panel builders and machine builders.

Get a Quick Quote for a Rittal 9684010

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9684010?

Enquire Now

FAQs

The SV 9684.010 busbar is supplied as a single 985 mm piece with integral punchings and 11.5 mm holes. Use standard fasteners through the punched holes to mount into compatible busbar supports, following DIN EN 13 601 guidelines. Confirm the hole spacing matches your enclosure’s mounting pattern to ensure proper alignment.

The busbar is made from E-Cu F30 with a 50 mm by 10 mm cross-section and a length of 985 mm. Copper weight is 4.38 kg per piece, and the pack contains 1 piece. It conforms to DIN EN 13 601, with a hole diameter of 11.5 mm and standard punched patterns for reliable connections.

Yes. The SV 9684.010 busbar is designed to DIN EN 13 601 specifications and uses E-Cu F30 copper. It is also classified under ETIM 9 EC001522 and ECLASS 8.0 27370303, which aids in consistent cataloging and procurement across systems.

Integral punchings provide a precise hole pattern, improving mounting accuracy and reducing the need for field drilling. This leads to faster assembly, better electrical contact reliability, and less risk of misalignment under vibration or thermal cycling in industrial environments.

Each busbar weighs 4.38 kg of copper, with a total pack weight of 4.48 kg. It is shipped as a single piece per pack, 985 mm in length, featuring 11.5 mm holes and integral punchings for straightforward installation.