Rittal 9684012 Busbars - DIN EN 13 601

Part Number: 9684012

Manufacturer

Rittal

Part number

9684012

Category

Alt Part Number

SV 9684.012

Quick Summary

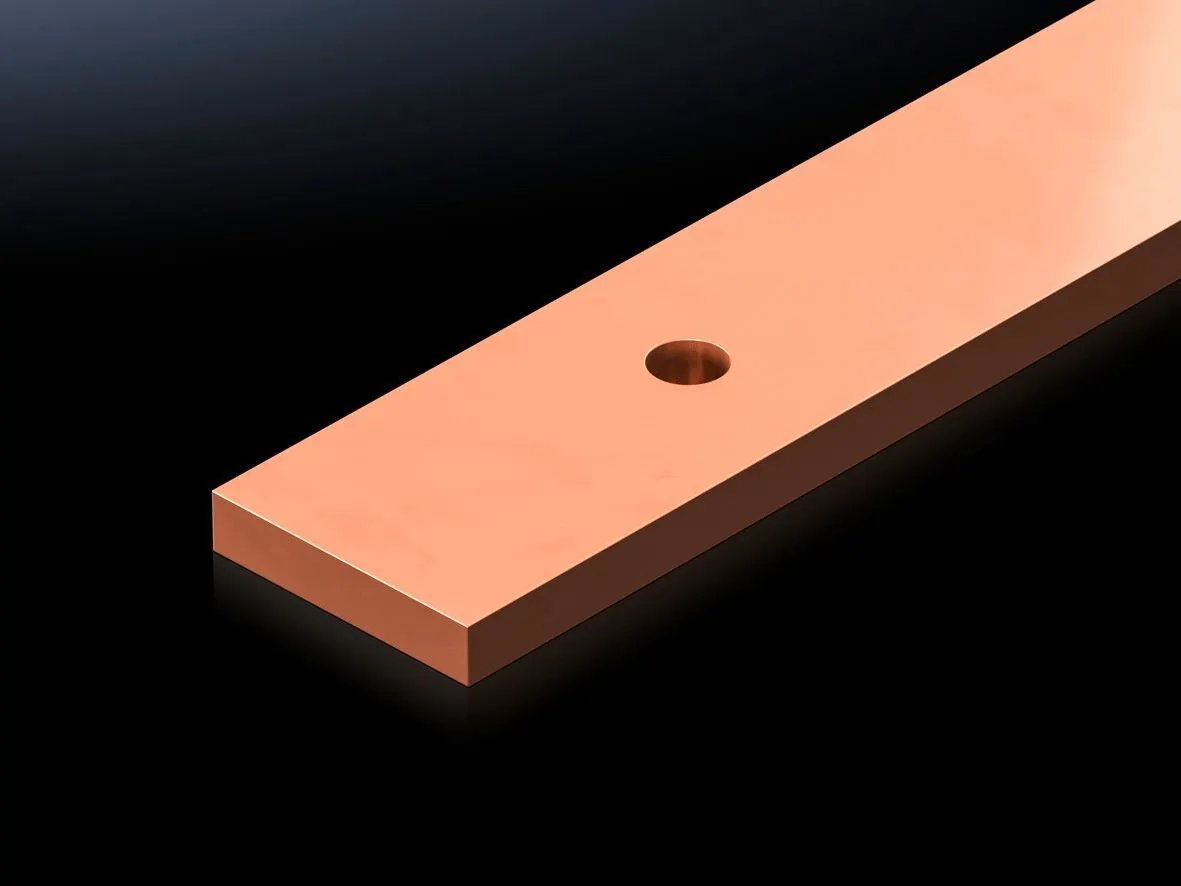

Rittal busbars 9684012 provide robust copper current distribution for switchgear and control panels. In practice, engineers face challenges with nonstandard punchings, misaligned mounting points, and time-consuming fabrication. This solution is designed to simplify assembly while maintaining high electrical performance, thanks to integral punchings and a consistent 1,185 mm length. It complies with DIN EN 13 601, uses E-Cu F30 for low resistivity, and offers a clearly defined cross-section of 50 mm x 10 mm with 11.5 mm hole diameter. The product ships as 1 pc per pack with a total weight of 5.44 kg, helping predict delivered mass and facilitating transport planning. By standardizing components, businesses reduce spare parts variety and speed up panel construction while ensuring reliability in power distribution applications.

Product Information

Extended Description

9684012 Rittal: SV busbars E-Cu with integral punchings, length 1185 mm

Article number

SV 9684.012

Product description

Busbars with integral punchings.

Material

E-Cu F30

Length

1,185 mm

Standards

DIN EN 13 601

Cross-section

50 mm x 10 mm

Hole diameter

11.5 mm

Packs of

1 pc(s).

Weight/pack

5.44 kg

Copper weight (kg per piece)

5.34

Customs tariff number

74071000

EAN

4028177951228

ETIM 9

EC001522

ECLASS 8.0

27370303

Product description

SV busbars E-Cu with integral punchings, length 1185 mm

Feature: Integral punchings simplify mounting and alignment. Business Impact: Reduces assembly time and drilling errors, improving panel build throughput. Application: Especially valuable in switchgear assemblies and control panels where quick, repeatable mounting is critical. Feature: E-Cu F30 material delivers low resistivity and high conductivity. Business Impact: Improves overall efficiency and reduces heating in conductors under load. Application: Ideal for high-current distribution in compact cabinet spaces and modular power distributions. Feature: Precise geometry—1,185 mm length with a 50 mm x 10 mm cross-section and 11.5 mm holes. Business Impact: Enables standardized fastener patterns and predictable thermal behavior, easing procurement and stock management. Application: Supports modular enclosure designs and scalable panel layouts. Feature: Copper weight 5.34 kg per piece and total pack weight 5.44 kg. Business Impact: Facilitates accurate logistics planning and cost control for bulk shipments. Application: Helpful for planning material handling in manufacturing lines and service programs. Feature: Pack of 1 piece per pack, DIN EN 13 601 compliant. Business Impact: Reduces waste and simplifies replacement strategies while ensuring regulatory alignment. Application: Suitable for single-service replacements and modular refurbishment projects.

Get a Quick Quote for a Rittal 9684012

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9684012?

Enquire Now

FAQs

Install by aligning the 50x10 mm cross-section with the enclosure’s fastening points, insert through the 11.5 mm punched holes, and secure with standard hardware. The 1,185 mm length is designed for consistent fit within typical switchgear frames, reducing the need for trimming or custom fabrication and speeding up panel assembly.

The busbars use E-Cu F30 copper, delivering low resistivity and reliable conductivity under load. They are manufactured to the DIN EN 13 601 standard, with punchings that ensure precise hole placement and consistent electrical paths, supporting safe and compliant power distribution in control panels and switchgear.

Yes. The cross-section is 50 mm by 10 mm and the holes have a 11.5 mm diameter, matching standard mounting patterns for many enclosure families. This compatibility simplifies installation, reduces bespoke fabrication, and improves interchangeability across multiple projects.

Each piece weighs 5.34 kg, with packs listed as 1 piece per pack and a total pack weight of 5.44 kg. This predictable weight assists logistics, warehousing, and cost planning for routine replacements or stock replenishment in service contracts.

Integral punchings enable rapid mounting without additional drilling, reducing assembly time and potential misalignment. The standardized length and hole pattern improve sourcing and reduce spare parts variety, delivering lower total cost of ownership and faster project turnover in panel fabrication and maintenance programs.