Rittal SV 9686.536 busbar - DIN EN 13 601 with punchings

Part Number: 9686536

Quick Summary

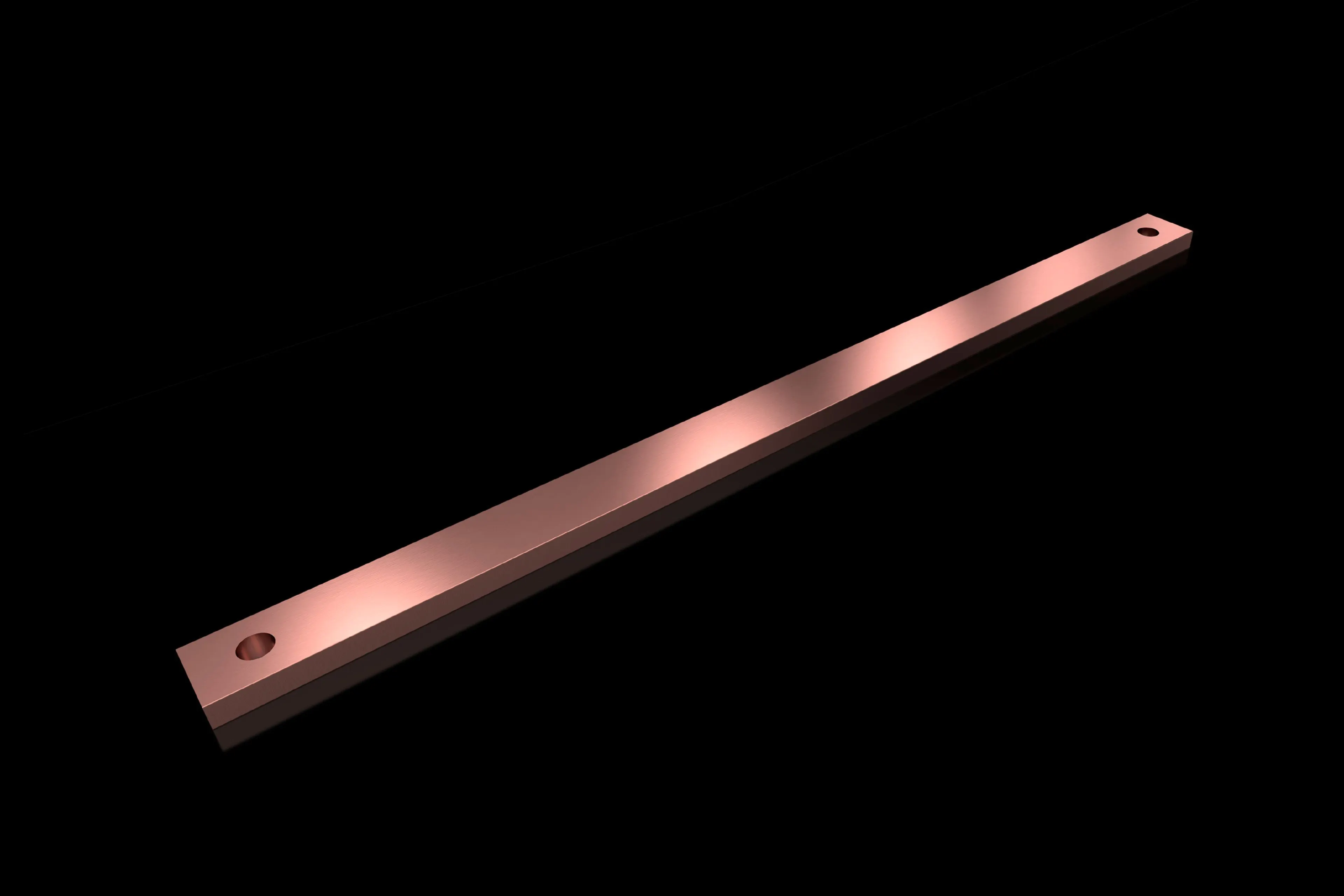

Rittal SV 9686.536 busbar is a copper distribution conductor for control cabinets and switchgear. Engineers often struggle with mismatched width, limited mounting options, and lengthy installation lead times. Standards-compliant to DIN EN 13 601, ETIM EC000329, and ECLASS 27400605, it simplifies sourcing and cross‑vendor compatibility. For manufacturers, the combination of PE/PEN busbar capability, copper conductivity, and integral holes supports faster assembly and reliable performance in automation environments. The product's 500 mm length and 30x10 mm cross-section align with common enclosure layouts, reducing custom fabrication. With a pack of two and a defined copper weight per piece, planners model cost and logistics with confidence. In practice, integrators report smoother commissioning and fewer field modifications when standard components like SV 9686.536 are used.

Product Information

Extended Description

9686536 Rittal: SV PE/PEN busbar E-Cu, WH: 30x10 mm, L: 500 mm

Article number

SV 9686.536

Product description

With integral holes.

Material

E-Cu

Ø hole

11.5 mm

Dimensions

Length: 500 mm

To fit

Width: = 600 mm

Cross-section

30 mm x 10 mm

Packs of

2 pc(s).

Weight/pack

2.66 kg

Copper weight (kg per piece)

1.32

Customs tariff number

74071000

EAN

4028177934795

ETIM 9

EC000329

ECLASS 8.0

27400605

Product description

SV PE/PEN busbar E-Cu, WH: 30x10 mm, L: 500 mm

Copper conductor with E-Cu material delivers high conductivity and lower resistance, translating to improved efficiency and reduced heat in high-current distribution within control panels. This directly supports energy savings and longer component life in demanding automation environments. The 30x10 mm cross-section, combined with a 500 mm length, provides predictable current-carrying capacity while fitting common 600 mm wide enclosures, minimizing install-time adjustments and waste. Integral mounting holes (Ø 11.5 mm) enable fast, drill-free mounting, lowering labor costs and speeding up panel assembly. Packs of two with a total weight of 2.66 kg per pack and 1.32 kg copper per piece enable accurate logistics planning and consistent stock management. PE/PEN busbar construction enhances safety and reliability in shared grounding schemes, simplifying compliance and procurement. Standards alignment to DIN EN 13 601, coupled with ETIM EC000329 and ECLASS 27400605 classifications, reduces procurement ambiguity and improves cross‑vendor compatibility. These features collectively support faster commissioning, reduced field modifications, and predictable performance in modern switchgear.

Get a Quick Quote for a Rittal 9686536

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9686536?

Enquire Now

FAQs

Yes. The SV 9686.536 is designed for standard control cabinet spaces and includes integral mounting holes with a 11.5 mm diameter, enabling straightforward, drill-free installation within typical enclosure widths. This reduces modification time and ensures a secure, vibration-resistant connection in high-current layouts.

The busbar features a 30x10 mm cross-section and a length of 500 mm. It is sold in packs of two pieces, with a total pack weight of about 2.66 kg and copper weight of 1.32 kg per piece, enabling precise logistics and inventory planning for assembly lines.

This PE/PEN copper busbar is ideal for high-current distribution and grounding schemes in control cabinets and switchgear. Its E-Cu construction, 30x10 mm profile, and integral holes support rapid wiring, reliable current paths, and clean, compliant grounding connections in automation installations.

The component is designed to DIN EN 13 601 compliant hardware, and is classified under ETIM EC000329 and ECLASS 27400605, facilitating consistent sourcing and interoperability across vendors. The customs tariff number is 74071000, aiding import and duty planning for international projects.

Integral holes eliminate on-site drilling, speeding assembly and reducing labor costs. The explicit copper weight per piece and pack size enable accurate material budgeting, while reliable conductivity improves system efficiency and reduces thermal issues. Overall, you gain faster commissioning, predictable logistics, and lower total cost of ownership in panel builds.