Rittal 9686540 Busbar - With integral holes DIN EN 13601

Part Number: 9686540

Quick Summary

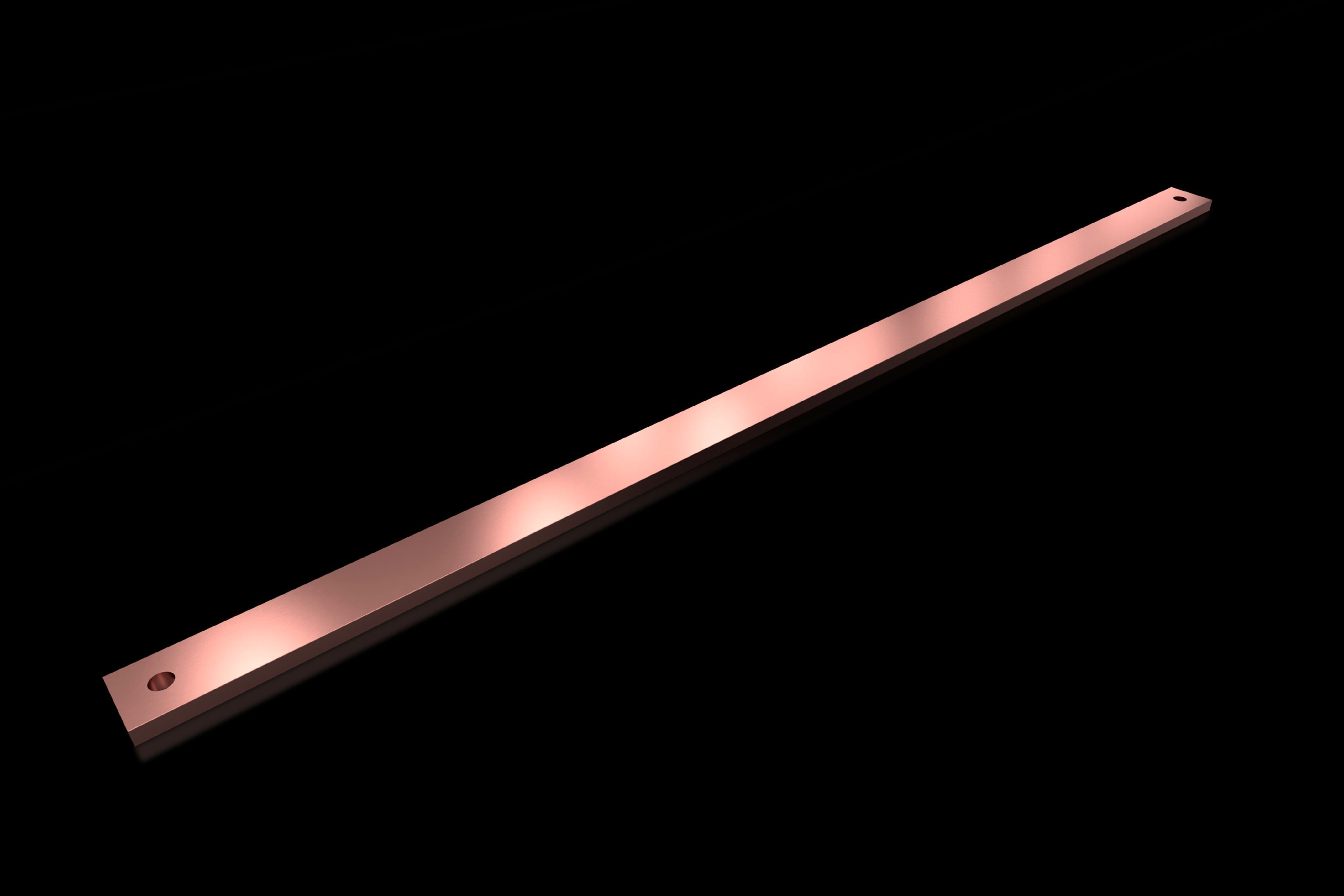

The Rittal 9686540 busbar is a copper conductor designed for reliable electrical distribution inside control cabinets. It provides a compact, rigid connection path that helps maximize enclosure space while maintaining low resistance. Engineers often struggle with mounting precision and installation speed; this busbar’s 40x10 mm cross-section, 900 mm length, and integral holes streamline alignment and rapid mounting. The product aligns with DIN EN 13 601 and is catalogued under ETIM EC000329 and ECLASS 27400605, offering traceability in procurement systems. By standardizing on this component, panels gain predictable copper weight, fewer part variants, and easier stocking, improving lead times and maintenance planning. This supports efficiency gains and cost-effective spare parts management in manufacturing environments.

Product Information

Extended Description

9686540 Rittal: SV PE/PEN busbar E-Cu, WH: 40x10 mm, L: 900 mm

Article number

SV 9686.540

Product description

With integral holes.

Material

E-Cu

Ø hole

11.5 mm

Dimensions

Length: 900 mm

To fit

Width: = 1,000 mm

Cross-section

40 mm x 10 mm

Packs of

2 pc(s).

Weight/pack

6.44 kg

Copper weight (kg per piece)

3.2

Customs tariff number

74071000

EAN

4028177934900

ETIM 9

EC000329

ECLASS 8.0

27400605

Product description

SV PE/PEN busbar E-Cu, WH: 40x10 mm, L: 900 mm

Feature: E-Cu copper construction offers excellent electrical conductivity. Business Impact: Low resistance reduces voltage drop and heat, improving efficiency in power distribution. Application: Ideal for control cabinets and industrial panels where reliable copper conductors are required. Feature: 40x10 mm cross-section supports a balanced balance of current capacity and compact footprint. Business Impact: Enables denser layouts without sacrificing performance. Application: Suitable for modular cabinet designs where space is at a premium. Feature: 900 mm length with 11.5 mm holes provides standardized mounting and easy integration. Business Impact: Pre-punched holes ensure precise alignment and faster assembly, reducing panel build time. Application: Fast installation in enclosures with defined mounting points and hole patterns. Feature: Pack of two with total weight 6.44 kg simplifies procurement and stock management. Business Impact: Reduces downtime for replacements and lowers carrying costs. Application: Useful for projects needing redundancy and quick part replacement in manufacturing lines. Feature: Copper weight per piece 3.2 kg and DIN EN 13 601 compliance with ETIM/ECLASS classification. Business Impact: Improves procurement traceability and regulatory alignment, easing BOM integration. Application: Fits standard ERP and cataloging workflows, accelerating purchasing and job setup.

Get a Quick Quote for a Rittal 9686540

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9686540?

Enquire Now

FAQs

SV 9686.540 is designed for Rittal control cabinets with a 40x10 mm cross-section and 900 mm length, featuring 11.5 mm holes for straightforward mounting. It is supplied as a two‑pack and fits widths up to 1,000 mm, with integral punchings to speed installation.

Key specs include material E-Cu, cross-section 40x10 mm, length 900 mm, hole diameter 11.5 mm, weight per piece 3.2 kg, weight per pack 6.44 kg, and a two-piece pack. Customs tariff code is 74071000 and EAN is 4028177934900.

Yes, the product is documented to align with DIN EN 13 601 and is catalogued under ETIM EC000329 and ECLASS 27400605 for reliable procurement and technical classification.

Copper weight is 3.2 kg per piece, with a pack weight of 6.44 kg. Higher copper mass supports lower resistance and better current carrying capacity, contributing to lower heat generation in high‑demand panels.

The busbar features a 40x10 mm cross-section, 900 mm length, and 11.5 mm diameter holes. These integral holes enable precise, repeatable mounting in standardized cabinet layouts and simplify alignment during assembly.