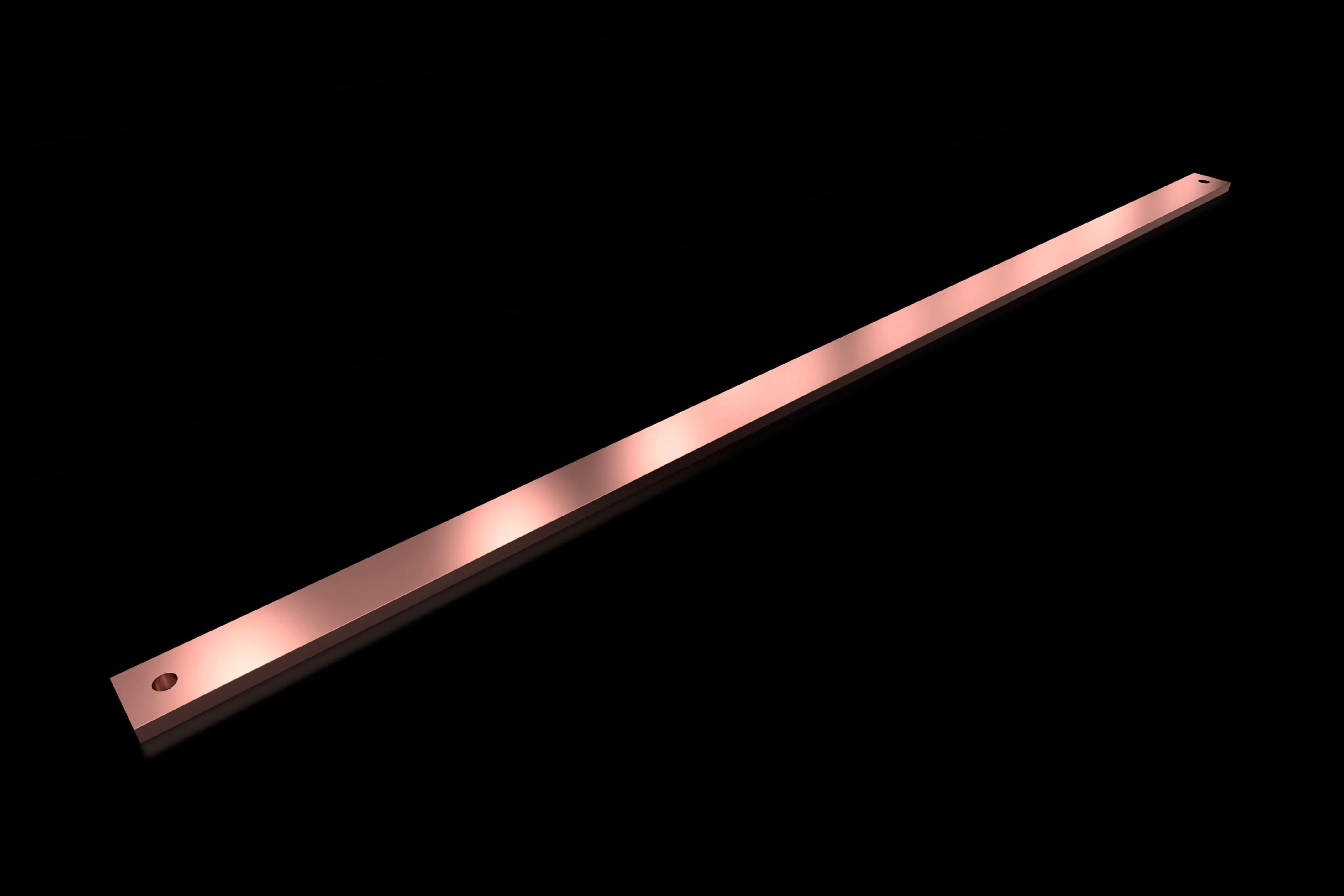

Rittal 9686542 Busbar E-Cu - DIN EN 13 601 integral holes

Part Number: 9686542

Quick Summary

Rittal busbar SV 9686.542 provides a copper distribution path for reliable power transfer inside industrial enclosures and control cabinets. Engineers often face misaligned punched holes, insufficient current capacity, and extended installation times; this busbar addresses those pain points through integral holes and a precise 1,100 mm length. It aligns with DIN EN 13 601, ETIM EC000329, and ECLASS 27400605, supporting accurate procurement, data exchanges, and regulatory compliance. With a 40x10 mm cross-section and copper weight of 3.92 kg per piece, the design delivers high conductivity while the 2 pc per pack packaging simplifies stocking and maintenance in demanding environments.

Product Information

Extended Description

9686542 Rittal: SV PE/PEN busbar E-Cu, WH: 40x10 mm, L: 1100 mm

Article number

SV 9686.542

Product description

With integral holes.

Material

E-Cu

Ø hole

11.5 mm

Dimensions

Length: 1,100 mm

To fit

Width: = 1,200 mm

Cross-section

40 mm x 10 mm

Packs of

2 pc(s).

Weight/pack

7.9 kg

Copper weight (kg per piece)

3.92

Customs tariff number

74071000

EAN

4028177934832

ETIM 9

EC000329

ECLASS 8.0

27400605

Product description

SV PE/PEN busbar E-Cu, WH: 40x10 mm, L: 1100 mm

The SV PE/PEN busbar uses a copper E-Cu cross-section of 40 mm by 10 mm, delivering low electrical resistance to reduce I²R losses while supporting compact enclosure layouts. This feature translates directly into measurable efficiency gains and cooler operating temperatures in power distribution paths. Practical installation benefits include integral punched holes (Ø 11.5 mm) that speed mounting and ensure precise alignment with minimal field drilling, reducing project build times and the risk of misfit components. The 1,100 mm length is designed to fit standard enclosures while maintaining ample contact area for robust connections; two-piece packaging streamlines stock management and service planning for high-demand assemblies. Compatibility with standard enclosure widths (to fit around 1,200 mm) simplifies procurement and reduces engineering rework. Data-grade compatibility is enhanced by ETIM and ECLASS classifications that ease ERP integration and supplier onboarding. Overall, the busbar supports compliance, traceability, and long-term maintenance in industrial environments.

Get a Quick Quote for a Rittal 9686542

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9686542?

Enquire Now

FAQs

To install the SV 9686.542 busbar, align the 40x10 mm copper bar with the enclosure mounting points and insert the 11.5 mm holes over compatible fasteners. Use the two-hole pattern to secure the piece firmly, ensuring the L1100 length fits within the available depth. The pre-punched holes reduce on-site drilling and help maintain precise alignment for reliable connections.

The 40x10 mm cross-section in E-Cu provides low resistance and high conductivity suitable for power distribution within control cabinets. While actual current depends on voltage, temperature rise, and connection quality, users can expect improved current carrying capacity over smaller conductors, reduced I²R losses, and cooler operating temperatures, supporting longer component life and fewer service interruptions.

Yes. The busbar is designed to fit standard enclosure widths around 1,200 mm, with integral holes that align to common mounting patterns. Its 1,100 mm length provides flexibility in enclosure designs, and the 11.5 mm holes facilitate quick, repeatable mounting. Always verify enclosure internal clearance and connector spacing for your specific installation.

Procurement references include DIN EN 13 601 for safety and interoperability. Data classifications align with ETIM EC000329 and ECLASS 27400605, supporting accurate cataloging and ERP integration. The product carries GTIN 4028177934832 and EAN 4028177934832, with a two-pack packaging that aids stock control and replenishment in purchasing workflows.

The copper weight per piece is 3.92 kg, with a 2-piece pack that reduces stocking complexity. Pre-punched holes speed installation and minimize field modifications, lowering maintenance downtime. Improved conductivity and reduced resistance translate to energy savings and cooler equipment operating conditions, contributing to faster project ramp-up, fewer reworks, and a favorable return on investment over the system’s life cycle.