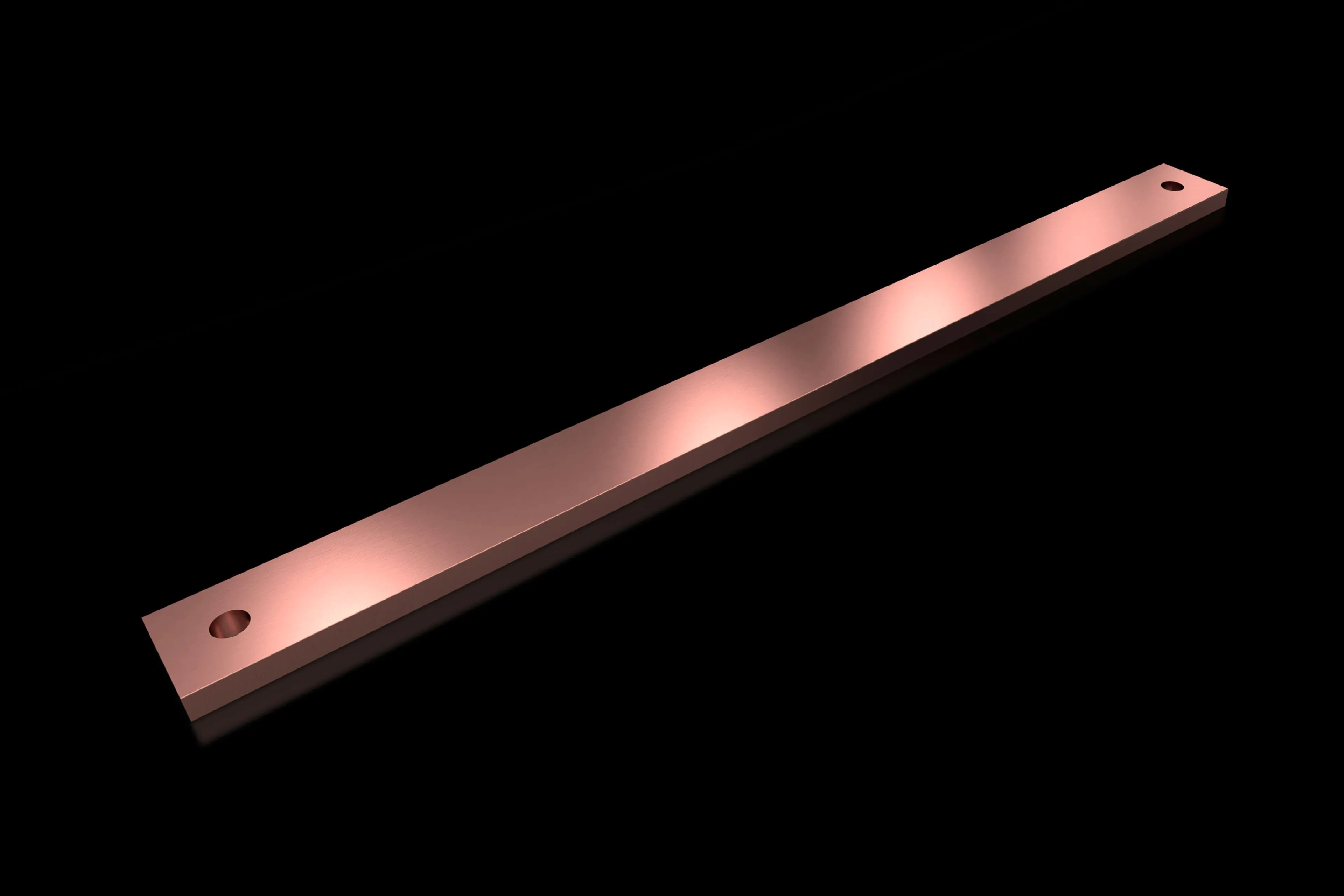

Rittal 9686546 Busbar - DIN EN 13 601, Integral punchings

Part Number: 9686546

Quick Summary

Rittal busbar 9686546 is a copper busbar designed for reliable current distribution in switchgear and control panels. Engineers often struggle with hole misalignment and inconsistent copper weights that slow installation and complicate stocking. The solution complies with DIN EN 13 601 and aligns with ETIM EC000329 and ECLASS 27400605, supporting accurate procurement data. By offering a 40x10 mm cross-section, 500 mm length, and integral punchings, it enables scalable, repeatable installations and easier stocking. This combination translates to reduced commissioning time and lower lifecycle costs, making it ideal for control panels, distribution blocks, and machine builds.

Product Information

Extended Description

9686546 Rittal: SV PE/PEN busbar E-Cu, WH: 40x10 mm, L: 500 mm

Article number

SV 9686.546

Product description

With integral holes.

Material

E-Cu

Ø hole

11.5 mm

Dimensions

Length: 500 mm

To fit

Width: = 600 mm

Cross-section

40 mm x 10 mm

Packs of

2 pc(s).

Weight/pack

3.58 kg

Copper weight (kg per piece)

1.77

Customs tariff number

74071000

EAN

4028177934863

ETIM 9

EC000329

ECLASS 8.0

27400605

Product description

SV PE/PEN busbar E-Cu, WH: 40x10 mm, L: 500 mm

Feature: E-Cu copper material with a 40x10 mm cross-section delivers high electrical conductivity, reducing resistance and heat generation. Business Impact: Lowers operating temperatures and improves energy efficiency in dense panel layouts. Application: Suitable for switchgear and control cabinets where space is at a premium. Feature: Integral holes with 11.5 mm Ø and overall length of 500 mm simplify mounting and alignment. Business Impact: Speeds installation, reduces hardware requirements, and minimizes misalignment risk. Application: Fits standard mounting patterns in modular enclosures and Rittal systems. Feature: Packs of 2 with a weight per pack of 3.58 kg and copper weight of 1.77 kg per piece provide predictable handling and inventory planning. Business Impact: Streamlines procurement, improves logistics, and supports batch traceability. Application: Ideal for stocking in distribution bays and procurement catalogs. Feature: Dimensional data specify WH 40x10 mm and L 500 mm with a width-fit specification of 600 mm. Business Impact: Ensures compatibility with enclosure widths and reduces need for cutting or rework. Application: Widely applicable to DIN-standard enclosures and modular assemblies. Feature: Certifications and classifications, including DIN EN 13 601 alignment and ETIM/ECLASS references, support compliance and data-driven purchasing. Business Impact: Improves supplier qualification and procurement accuracy, reducing risk in enterprise projects. Application: Used across industrial automation projects, from machine builders to panel manufacturers.

Get a Quick Quote for a Rittal 9686546

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9686546?

Enquire Now

FAQs

Yes. The SV 9686.546 uses a 40x10 mm cross-section with 11.5 mm diameter holes and a 500 mm length, designed to fit common DIN EN 13 601 compliant panels and standard enclosure cutouts. The integral punchings streamline mounting, reducing the need for custom fabrication.

The busbar is made of E-Cu with a cross-section of 40x10 mm and length of 500 mm. Copper weight per piece is 1.77 kg, and each pack weighs 3.58 kg. Holes are 11.5 mm in diameter, enabling reliable fastening in typical distribution applications.

This busbar is ideal for electrical distribution in switchgear and control panels, machine builds, and distribution blocks where a robust copper current path is required. Its 500 mm length and 40x10 mm cross-section support compact, scalable installations in mid-to-large panels.

The product aligns with DIN EN 13 601 for structural and dimensional compliance and includes ETIM 9 EC000329 and ECLASS 8.0 27400605 classifications, aiding data-driven sourcing and ERP integration. Specific CE or IP certifications are not listed in the provided data.

The integral holes and precise dimensions reduce assembly time and fastening hardware, while the copper’s high conductivity lowers heat losses. Packaged in standard lengths and weights, it simplifies stocking, reduces risk of mismatched components, and supports longer maintenance intervals in dense panel environments.