Rittal SV 9686.586 busbar - To DIN EN 13 601

Part Number: 9686586

Quick Summary

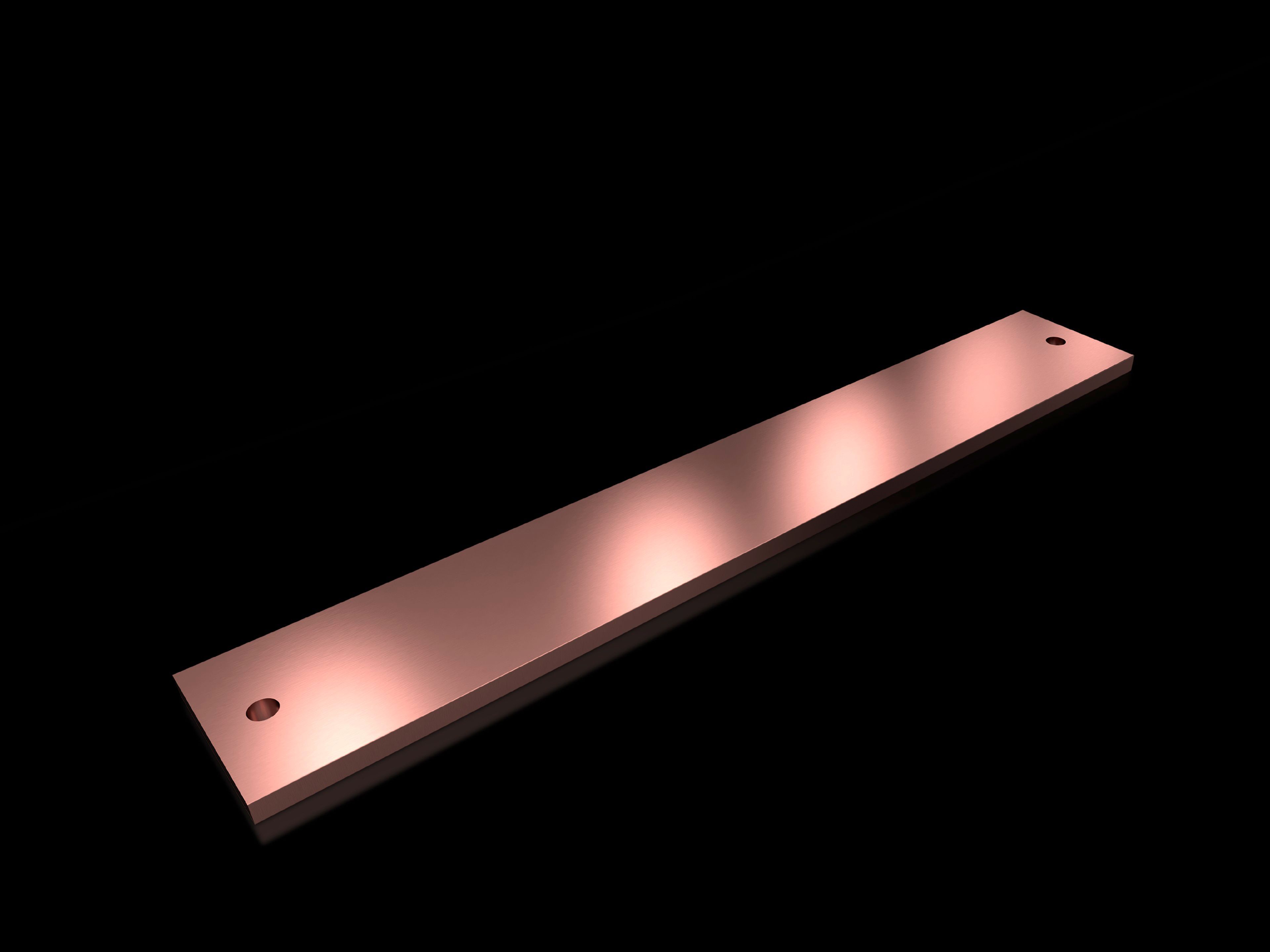

Rittal SV 9686.586 busbar enables efficient power distribution inside electrical cabinets. Upgrade projects often stumble over space constraints, corrosion risk, and mounting compatibility, driving downtime. Key standards include DIN EN 13 601 compliance, ETIM 9 EC000329, and ECLASS 8.0 27400605 to support procurement and interoperability. This copper busbar, WH: 80x10 mm, L: 500 mm, delivers reliable current paths with integral holes, simplifying installation, reducing maintenance, and lowering total cost of ownership for panel builders and system integrators.

Product Information

Extended Description

9686586 Rittal: SV PE/PEN busbar E-Cu, WH: 80x10 mm, L: 500 mm

Article number

SV 9686.586

Product description

With integral holes.

Material

E-Cu

Ø hole

11.5 mm

Dimensions

Length: 500 mm

To fit

Width: = 600 mm

Cross-section

80 mm x 10 mm

Packs of

2 pc(s).

Weight/pack

7.18 kg

Copper weight (kg per piece)

3.56

Customs tariff number

74071000

EAN

4028177934788

ETIM 9

EC000329

ECLASS 8.0

27400605

Product description

SV PE/PEN busbar E-Cu, WH: 80x10 mm, L: 500 mm

Feature: E-Cu copper provides excellent electrical conductivity and thermal performance. This translates to lower resistance, reduced energy loss, and cooler operating temperatures under high-current loads. In practice, panel builders see improved reliability and longer service life when wiring busbars in control cabinets, especially in dense layouts where heat management is critical. Feature: Dimensions and cross-section 80x10 mm with a 500 mm length. These dimensions enable straightforward integration into standard enclosure widths up to 600 mm and align with common mounting patterns, reducing custom fabrication and accelerating project timelines. Feature: Integral holes with Ø 11.5 mm and punched design. Installation becomes faster with pre-punched holes, minimizing hardware handling and misalignment while improving mechanical robustness in vibration-prone environments. Feature: Packaging and weight details. Packs of 2 pieces, with a weight of 7.18 kg per pack and 3.56 kg per piece. This supports accurate shipping planning, stock control, and predictable lead times for large cabinet rollouts. Feature: Certifications and classifications. DIN EN 13 601 compliance, ETIM 9 EC000329, and ECLASS 8.0 27400605 streamline procurement data management, enabling efficient ERP integration and cross-brand compatibility in industrial automation projects.

Get a Quick Quote for a Rittal 9686586

Chat with us on WhatsApp - fast responses guaranteed

Need to speak with someone? We'll call you back within 2 hours during business hours

Interested in Rittal 9686586?

Enquire Now

FAQs

The SV 9686.586 busbar is designed for 80×10 mm cross-section with a 500 mm length and 11.5 mm holes, suitable for integration in electrical cabinets and control panels up to standard enclosure widths. Its copper E-Cu construction supports reliable current paths and easy mounting within typical enclosure frameworks.

It features integral punchings and pre-drilled holes, reducing assembly steps and avoiding additional drilling onsite. The pieces come in packs of two with a total pack weight of 7.18 kg, facilitating straightforward logistics and faster commissioning in panel upgrade projects.

Key classifications include DIN EN 13 601 compliance, ETIM 9 EC000329, and ECLASS 8.0 27400605. These standards support consistent procurement data, cross-brand compatibility, and easier ERP integration, ensuring your cabinet assemblies meet industry expectations.

Yes. The E-Cu material and 80×10 mm cross-section deliver good conductivity and structural robustness for typical control cabinet power paths. With a weight of 3.56 kg per piece, it provides reliable current handling while maintaining manageable install weight and space within standard enclosures.

Each order contains packs of 2 busbars, with a total pack weight of 7.18 kg. Individual pieces weigh 3.56 kg. This packaging supports predictable shipping costs, efficient inventory planning, and smooth deployment in multi-unit cabinet projects.